A kind of preparation method of physical metamorphic semi-solid die-casting of high thermal conductivity baking pan

A high thermal conductivity, semi-solid technology, applied in the field of baking pan manufacturing technology, can solve problems such as copper precipitation, achieve the effect of small crystal nucleus, avoid the use of ultra-high pressure, and uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

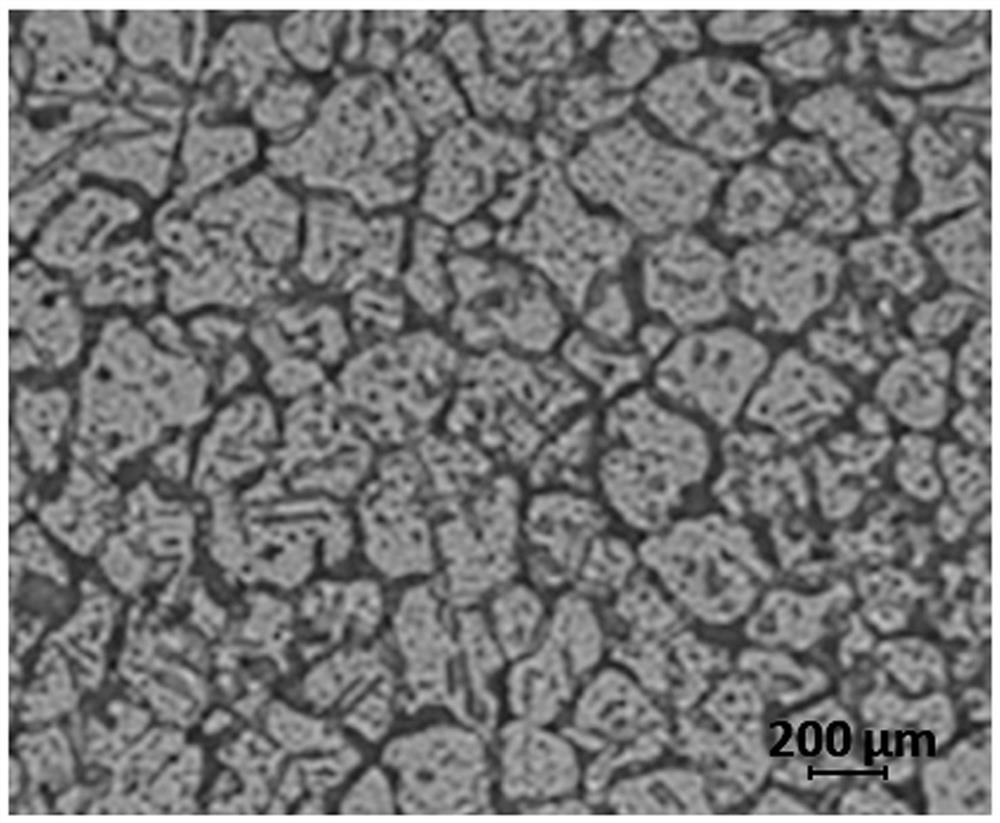

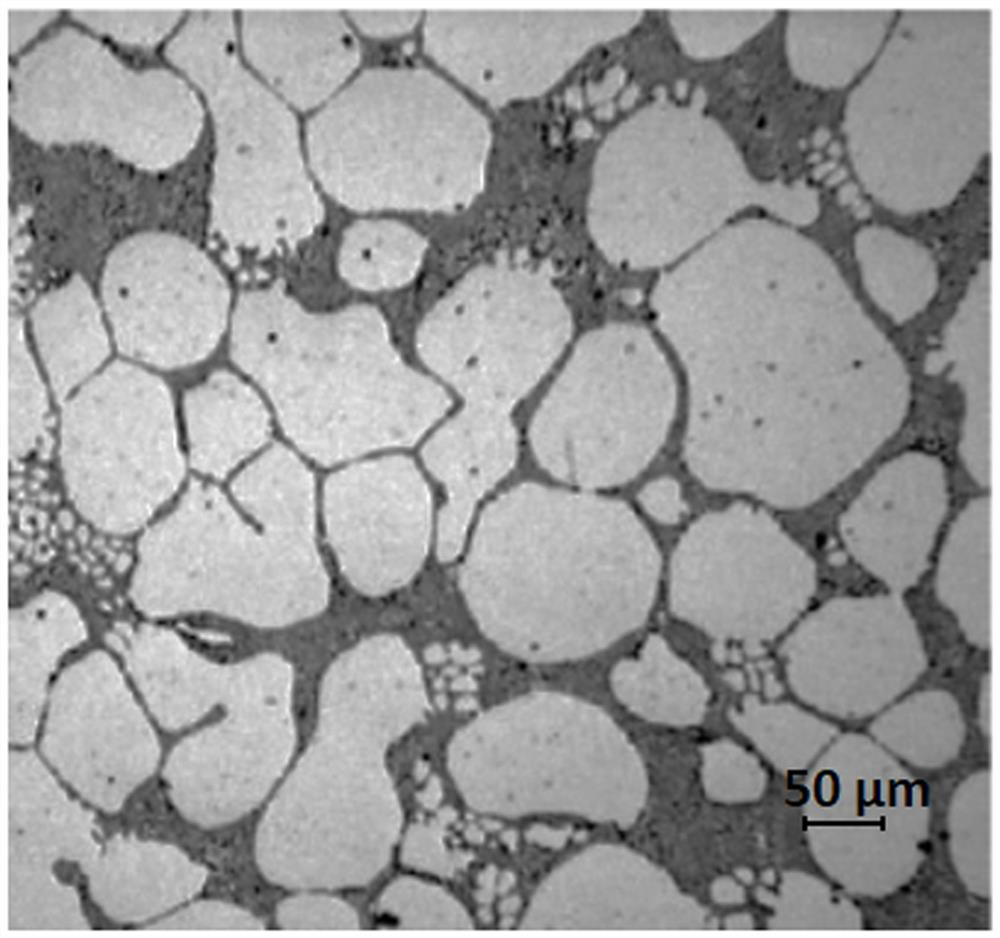

Image

Examples

Embodiment

[0035] In a preferred embodiment of the present invention, the physical modification semi-solid die-casting preparation method of the high thermal conductivity bakeware includes:

[0036] a. Put 40-60wt% of the total amount of aluminum alloy ingot into the melting furnace for melting, rapidly raise the temperature to 900-920°C, keep it for 15-20min, and the heating rate is 4~5°C / min;

[0037] b. Put the remaining aluminum alloy ingot into another melting furnace for melting, control the melting temperature at 640-660°C, and keep it warm for 0.5-1h;

[0038] c. Pour the molten aluminum in step a into the molten aluminum in step b to carry out metamorphic treatment;

[0039] d. Add the Al-5B alloy to the molten aluminum after the metamorphic treatment in step c, and keep it warm for 0.2-0.5h;

[0040] e. Add the Al-10Sr alloy to the molten aluminum obtained in step d, and keep it warm for 0.2-0.5h;

[0041] f. Refining, degassing and slag removal of molten aluminum;

[0042...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com