Mold with high-efficiency cooling water line

A technology for cooling water channels and water channels, applied in the field of thermoplastic molding molds, can solve the problems of reducing production efficiency, different cooling degrees, and increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

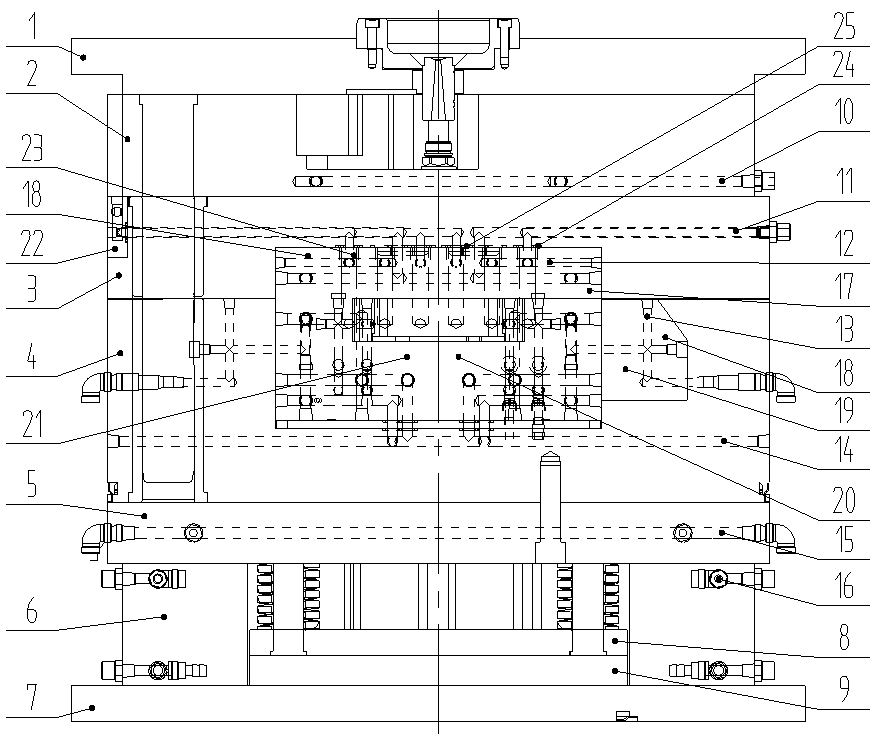

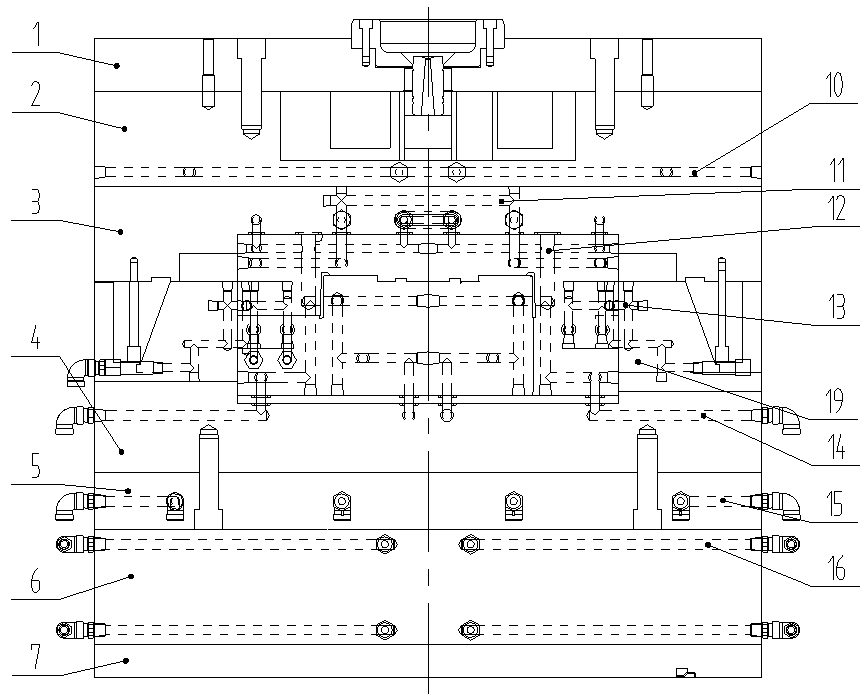

[0017] Specific embodiments of the invention will be described in detail below in conjunction with technical text and accompanying drawings.

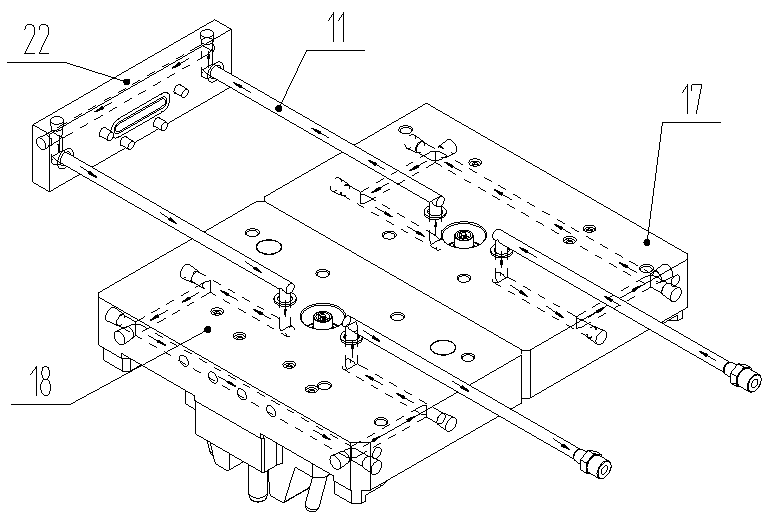

[0018] During the processing of mold inserts, when the first fixed mold insert 17 and the second fixed mold insert 18 are processed for the waterway, use the drilling machine to process the straight-through waterway, use the milling machine to process the cooling water well, and use the machining center to process the U-shaped connection groove and sealing ring groove ; During water transport block 22 waterway processing, utilize drilling machine to process the straight-through waterway of the second waterway 11, utilize machining center to process parallel waterway channel and sealing ring groove (see image 3 , 4 , 6, 7).

[0019]When assembling the mold, the guide post is fitted in the guide post hole processed by the runner plate 2, and the bolt passes through the bottom plate 1 of the fixed mold to lock and fix it with the runner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com