Waterborne system DLP 3D printing photosensitive resin

A photosensitive resin, 3D printing technology, applied in the direction of additive processing, can solve the problem of photosensitive resin pollution, and achieve the effect of solving the bad elongation at break, improving the elongation at break, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a water-based system DLP type 3D printing photosensitive resin, the preparation steps are:

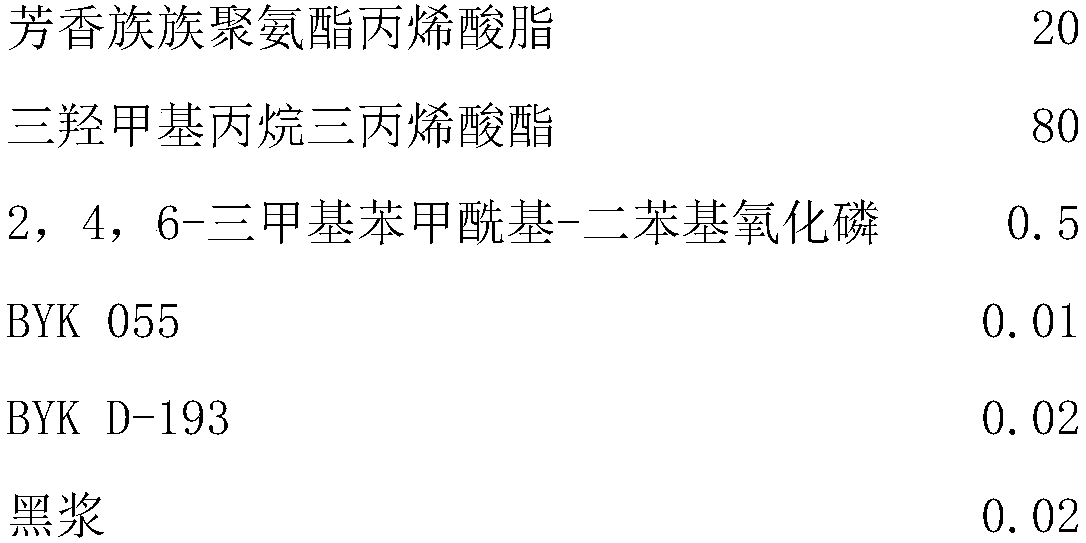

[0036] Step 1, content proportioning by weight parts:

[0037]

[0038] Step 2. Add monomers, resins, photoinitiators, defoamers, emulsifying dispersants, and pigments that have been weighed in proportion to the mixer in sequence, and mix them at a low speed to obtain a premixed solution. It is 400r / min, and the stirring time is 15min.

[0039] Step 3, high-speed stirring: after the premixed liquid in the stirrer is stirred at high speed for 15 minutes, a uniform mixed liquid is obtained, and the rotating speed of high-speed stirring is 1500 r / min.

[0040] Step 4. Filtration: After filtering the obtained mixed solution, a 3D printing photosensitive resin is obtained, and the mesh number of the filter is 100 mesh.

[0041] Use DLP equipment to print the model of the photosensitive resin prepared in the above steps, the surface of the model is smooth a...

Embodiment 2

[0043] A method for preparing a water-based system DLP type 3D printing photosensitive resin, the preparation steps are:

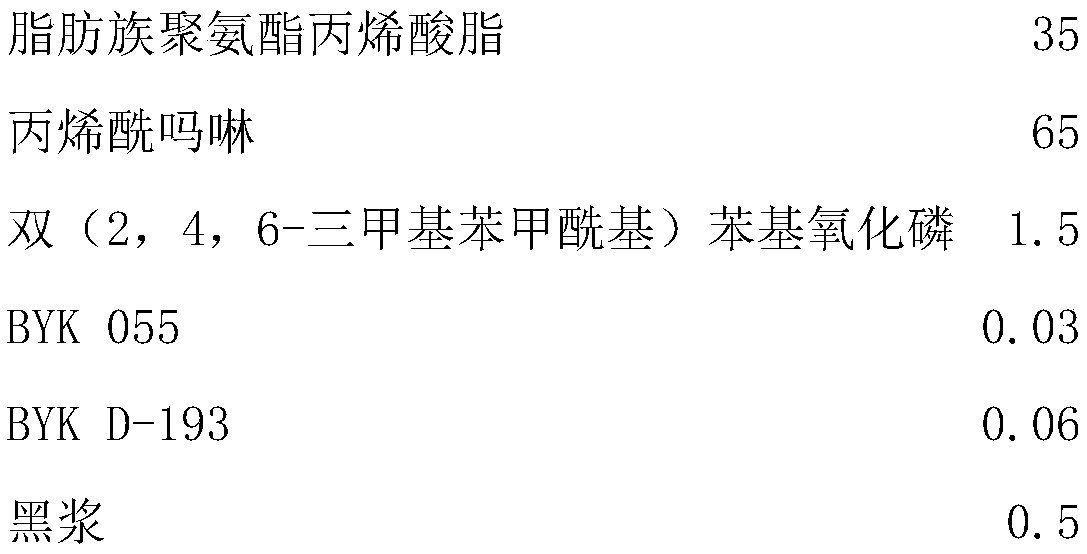

[0044] Step 1, content proportioning by weight parts:

[0045]

[0046] Step 2. Add monomers, resins, photoinitiators, defoamers, emulsifying dispersants, and pigments that have been weighed in proportion to the mixer in sequence, and mix them at a low speed to obtain a premixed solution. 500r / min, stirring time is 20min.

[0047] Step 3, high-speed stirring: after the premixed solution in the agitator is stirred at high speed for 15 minutes, a uniform mixed solution is obtained, and the rotating speed of the high-speed stirring is 1800 r / min.

[0048] Step 4. Filtration: After filtering the obtained mixed solution, a 3D printing photosensitive resin is obtained, and the mesh number of the filter is 100 mesh.

[0049] Use DLP equipment to print the model of the photosensitive resin prepared in the above steps, the surface of the model is smooth and th...

Embodiment 3

[0051] A method for preparing a water-based system DLP type 3D printing photosensitive resin, the preparation steps are:

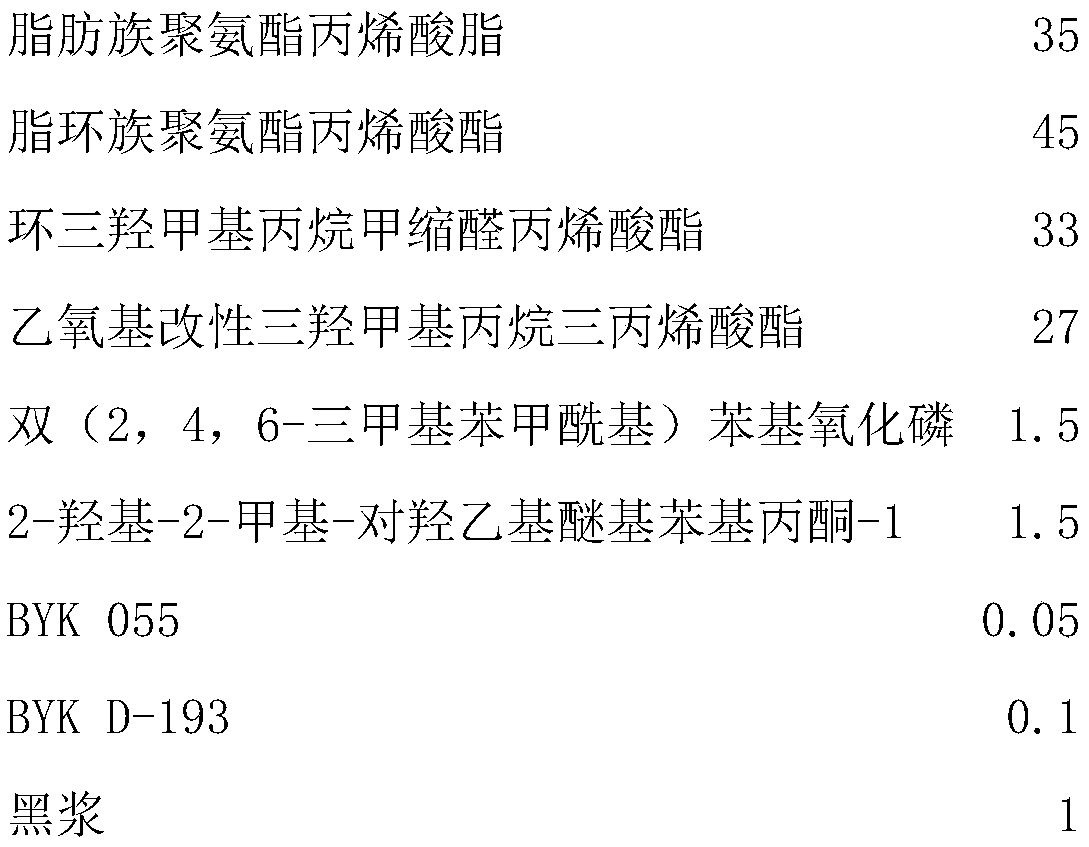

[0052] Step 1, content proportioning by weight parts:

[0053]

[0054] Step 2. Add monomers, resins, photoinitiators, defoamers, emulsifying dispersants, and pigments that have been weighed in proportion to the mixer in sequence, and mix them at a low speed to obtain a premixed solution. It is 600r / min, and the stirring time is 25min.

[0055] Step 3, high-speed stirring: after the premixed solution in the agitator is stirred at a high speed for 20 minutes, a uniform mixed solution is obtained, and the rotating speed of the high-speed stirring is 2200 r / min.

[0056] Step 4. Filtration: After filtering the obtained mixed solution, a 3D printing photosensitive resin is obtained, and the mesh number of the filter is 100 mesh.

[0057] Use DLP equipment to print the model of the photosensitive resin prepared in the above steps, the surface of the model ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com