Nano coating for inhibiting surface charge accumulation of epoxy resin and preparation method

A technology of nano-coating and epoxy resin, applied in the direction of coating, etc., can solve the problems of corroding metal, changing chemical composition, corrosion, etc., and achieve the effect of increasing DC flashover voltage, reducing surface charge accumulation, and easy migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

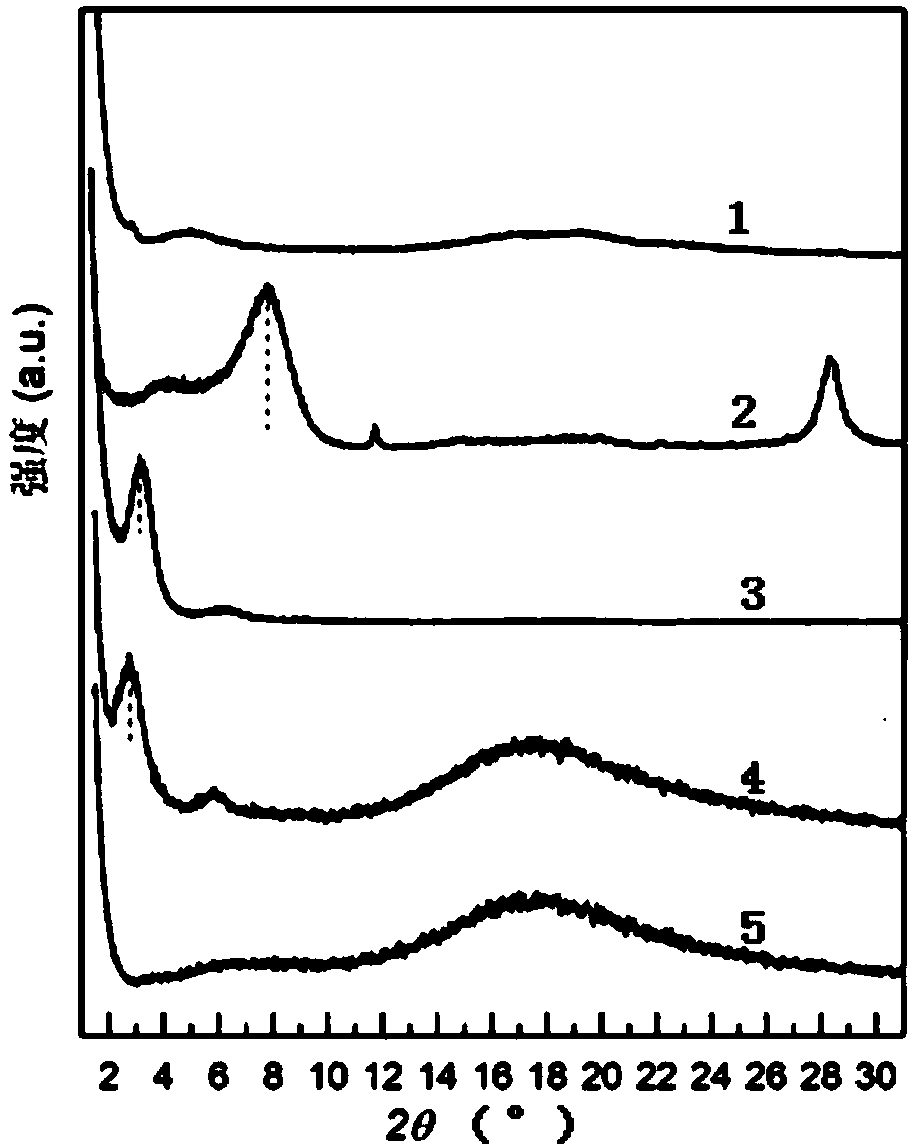

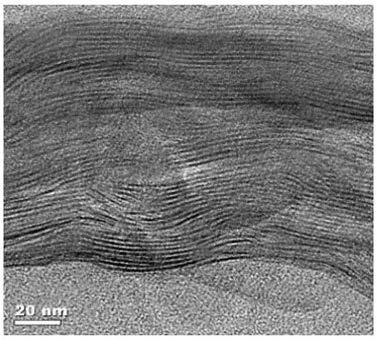

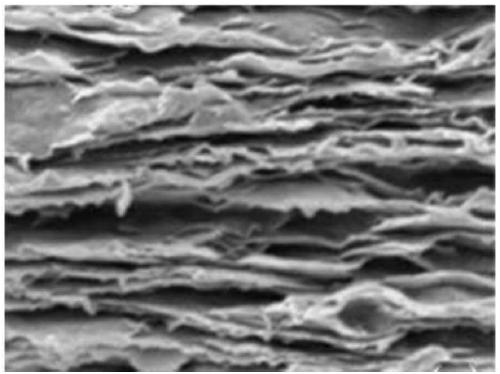

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a nano-coating dipping solution, comprising the following steps:

[0038] S1. Weigh MMT10g, disperse in 990g deionized water to form a suspension with a mass concentration of 1wt%, then stir at high speed for 5min, and use ultrasonic treatment for 15min;

[0039] S2. Add 6.67g PVA and deionized water to the suspension prepared in step S1, so that the PVA quality accounts for 40wt% of the total solid mass of PVA and MMT, and the total solid mass fraction in the solution is 1wt%, and the mixture is placed in a water bath , heated up to 90°C while stirring, and ultrasonically dispersed again for 15 minutes;

[0040] S3. After the PVA is completely dissolved, add 0.76g of the crosslinking agent GA, so that the ratio of the number of moles of GA to the total number of hydroxyl groups on the PVA chain is 1:20, and add 0.06g of catalyst HCl for the crosslinking reaction, and the number of moles of catalyst HCl The molar ratio of GA to GA is 1:5, and ult...

Embodiment 2

[0042] S1. Weigh MMT10g, disperse in 990g deionized water to form a suspension with a mass concentration of 1wt%, then stir at high speed for 8min, and use ultrasonic treatment for 20min;

[0043] S2. add 10g PVA and deionized water to the suspension prepared in step S1, make the PVA quality account for 50wt% of the total solid mass of PVA and MMT, the total solid mass fraction in the solution is 1wt%, the mixture is placed in a water bath, Raise the temperature to 90°C while stirring, and ultrasonically disperse again for 20 minutes;

[0044]S3. After the PVA is completely dissolved, add 1.14g of cross-linking agent GA, so that the ratio of the number of moles of GA to the total number of moles of hydroxyl groups on the PVA chain is 1:20, and add 0.06g of catalyst HCl for cross-linking reaction, and the number of moles of catalyst HCl The molar ratio of GA to GA is 1:5, and ultrasonication is performed for 20 minutes at a constant temperature to form a uniform and transparent...

Embodiment 3

[0046] S1. Weigh MMT10g, disperse in 990g deionized water to form a suspension with a mass concentration of 1wt%, then stir at high speed for 10min, and use ultrasonic treatment for 30min;

[0047] S2. add 12g PVA and deionized water to the suspension prepared in step S1, make the PVA quality account for 60wt% of the total solid mass of PVA and MMT, the total solid mass fraction in the solution is 2wt%, the mixture is placed in a water bath, Raise the temperature to 90°C while stirring, and ultrasonically disperse again for 30 minutes;

[0048] S3. After the PVA is completely dissolved, add 1.368g of cross-linking agent GA, so that the ratio of the number of moles of GA to the total number of moles of hydroxyl groups on the PVA chain is 1:20, and add 0.06g of catalyst HCl for the cross-linking reaction, and the number of moles of catalyst HCl The molar ratio of GA to GA is 1:5, and ultrasonication is performed for 30 minutes at a constant temperature to form a uniform and tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com