Method for preparing titanium-rich material with chlorination capacity from low-grade natural rutile

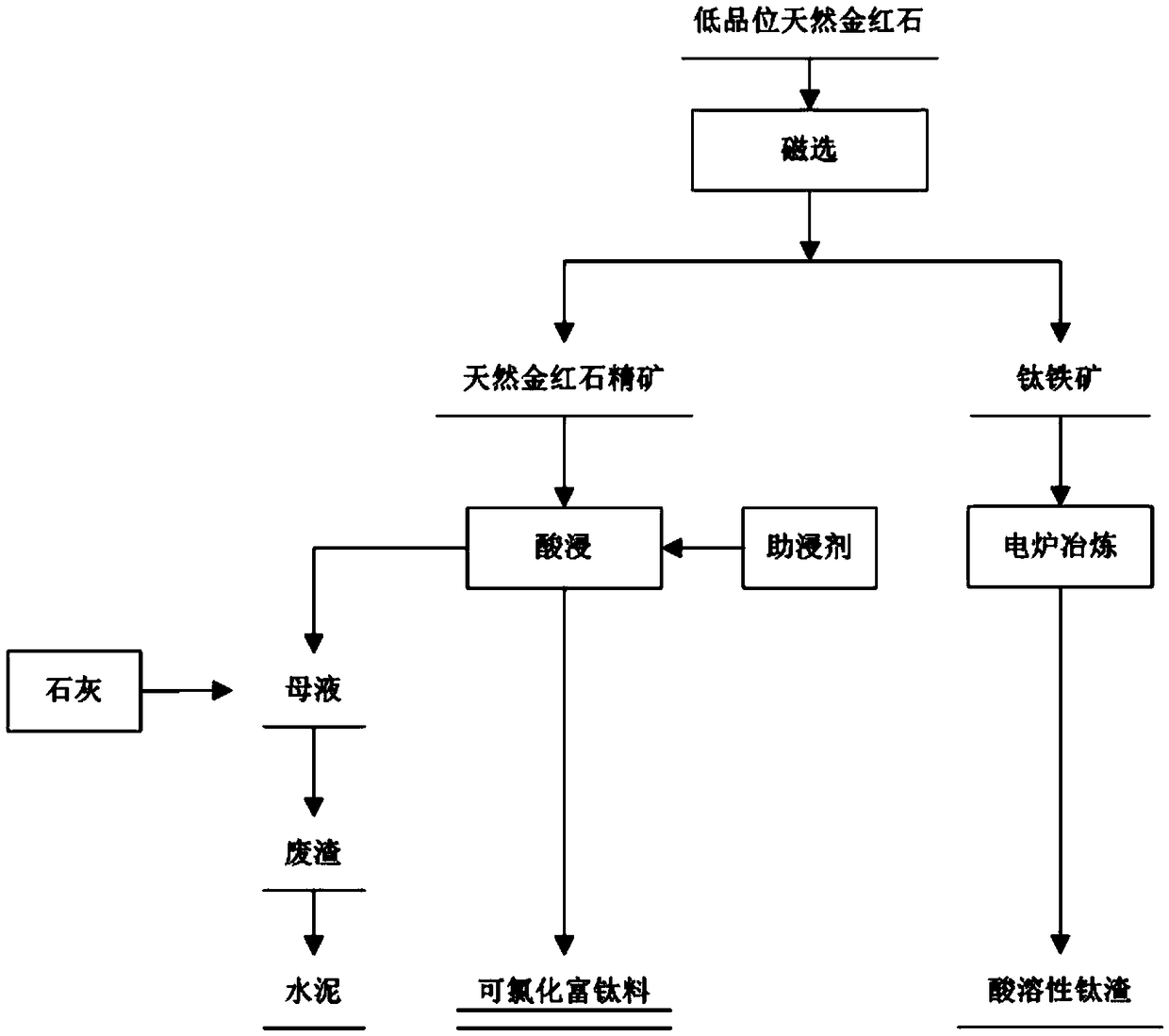

A natural rutile and low-grade technology, applied in the field of titanium chemical industry, can solve problems such as complex process flow, serious equipment corrosion, and high energy consumption, and achieve simple process flow, good impurity removal effect, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The low-grade natural rutile (wherein some component content is: TiO 2 : 60.17%, SiO 2 : 3.16%, CaO: 0.31%, MgO: 0.57%) for strong magnetic separation to separate natural rutile concentrate and ilmenite; weigh 100g of natural rutile concentrate, first add HCl solution with a concentration of 18%, liquid-solid The ratio is 4:1, and then add 40% HF solution and NH 4 F solid is used as leaching aid for leaching, the amount of HF solution is 1.0% of the quality of natural rutile concentrate used, NH 4 The dosage of F solid is 2.5% of the mass of the natural rutile concentrate used, the leaching reaction temperature is 80°C, the leaching reaction time is 2h, the leaching pressure is normal pressure, and then the solid-liquid separation is carried out; the separated solid material is deionized water Washing, the liquid-solid ratio is 3:1, after washing 3 times, filter, and then dry the filtered material at 110°C for 3 hours to obtain the chlorinable titanium-rich material; ...

Embodiment 2

[0034] The low-grade natural rutile (wherein some component content is: TiO 2 : 75.96%, SiO 2 : 3.74%, CaO: 0.24%, MgO: 0.37%) for strong magnetic separation to separate natural rutile concentrate and ilmenite; weigh 100g of natural rutile concentrate, first add H2O with a concentration of 20% 2 SO 4 solution, the liquid-solid ratio is 3:1, and then add HF solution with a concentration of 40% as a leaching agent for leaching. The amount of HF solution is 4.0% of the quality of natural rutile concentrate used. The reaction time is 1h, the leaching pressure is normal pressure, and then the solid-liquid separation is carried out; the separated solid material is washed with deionized water, and the liquid-solid ratio is 3:1. After washing 3 times, filter, and then the filtered material Dry at 110°C for 3 hours to obtain chlorinated titanium-rich material; then add quicklime and 0.1g / L calcium carbide dissolved in the acid leaching mother liquor to the separated acid leaching mot...

Embodiment 3

[0037] The low-grade natural rutile (wherein some component content is: TiO 2 : 68.74%, SiO 2 : 4.20%, CaO: 0.41%, MgO: 0.34%) for strong magnetic separation to separate natural rutile concentrate and ilmenite; weigh 100g of natural rutile concentrate, first add H 2 SO 4 solution and 20% phosphoric acid solution, the liquid-solid ratio is 3:1, and then NaF solid and KF solid are added as leaching aids for leaching. The amount of NaF solid is 2.0% of the quality of the natural rutile concentrate used, and the amount of KF solid It is 23% of the quality of the natural rutile concentrate used, the leaching reaction temperature is 94°C, the leaching reaction time is 1h, the leaching pressure is normal pressure, and then the solid-liquid separation is carried out; the separated solid material is washed with deionized water, and the liquid The solid ratio is 3:1, after washing 3 times, filter, and then dry the filtered material at 110°C for 3 hours to obtain chlorinable titanium-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com