Laser reactive cladding TiC ceramic reinforced iron matrix composite material and preparation method thereof

An iron-based composite material and cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of uneven coating, cracks, singleness, etc., to improve surface properties, improve bonding strength, and good metallurgical bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

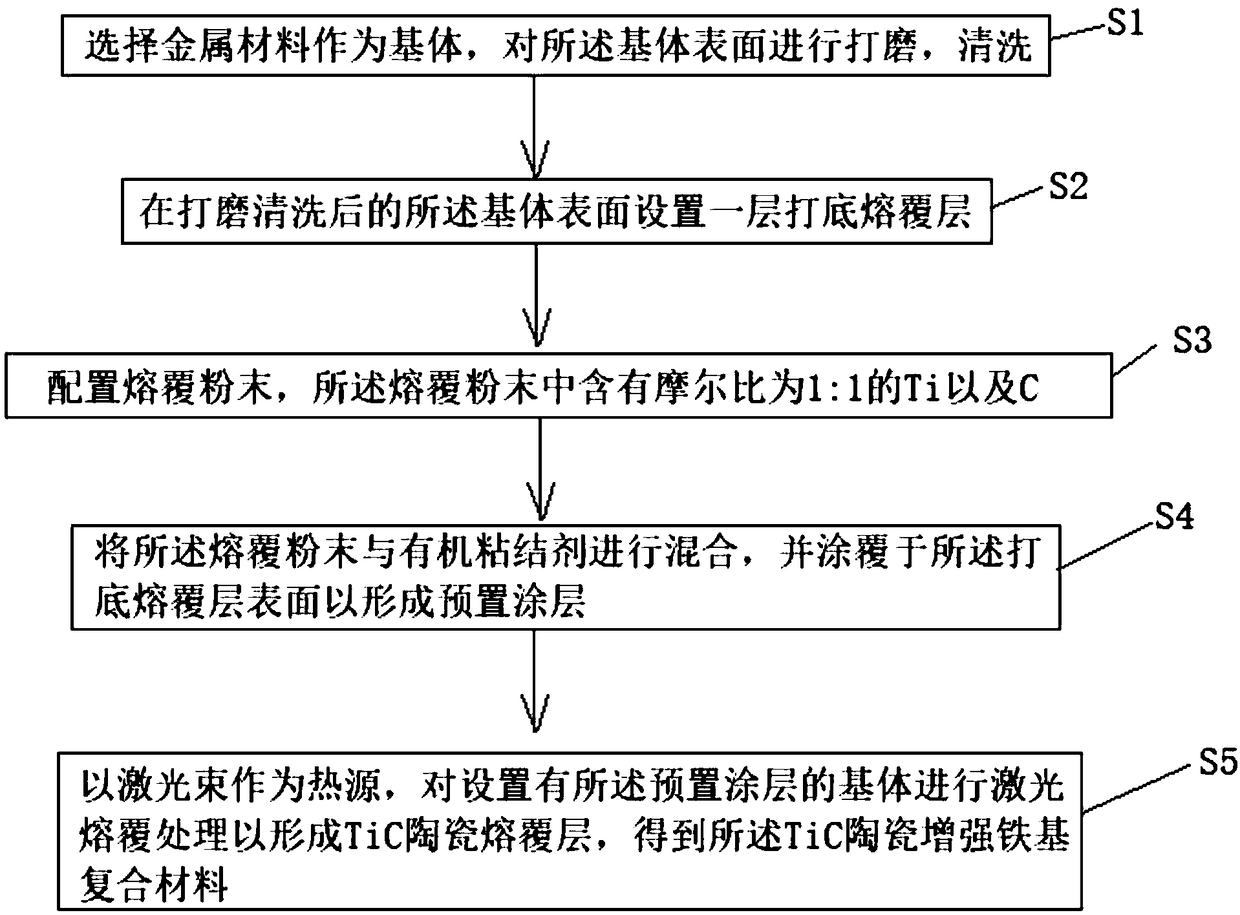

[0037] Such as figure 1 As shown, the preparation method of the laser reactive cladding TiC ceramic reinforced iron-based composite material according to the embodiment of the present invention includes:

[0038] S1, select a metal material as a substrate, and polish and clean the surface of the substrate.

[0039] There is no special limitation on the specific material composition of the substrate, for example, metal steel such as Q235 steel can be used.

[0040] In order to improve the bonding strength and performance between the surface cladding layer and the substrate, the surface of the substrate can be polished with sandpaper to remove oxides and oil stains on the surface, and cleaned with acetone to make the metal material fully contact with the cladding material .

[0041] S2, setting a layer of primer cladding layer on the surface of the ground and cleaned substrate.

[0042] Co-based self-fluxing alloys have excellent heat resistance, corrosion resistance, wear re...

Embodiment 1

[0061] The base material selected in this embodiment is Q235 steel. In order to improve the bonding strength and performance between the surface cladding layer and the substrate, the surface of the substrate was polished with sandpaper to remove oxides and oil stains on the surface, and cleaned with acetone.

[0062] The material of the bottom cladding layer is Co50 self-fluxing alloy. The bottoming cladding layer material is mixed with the alcohol solution of shellac to form a paste, after which the paste is coated on the surface of the substrate, and after being dried for 2 hours at 100 degrees Celsius, laser cladding is carried out (the scanning speed of the laser is 1.5 mm / s), forming a primer cladding layer with a thickness of 0.4mm on the surface of the substrate.

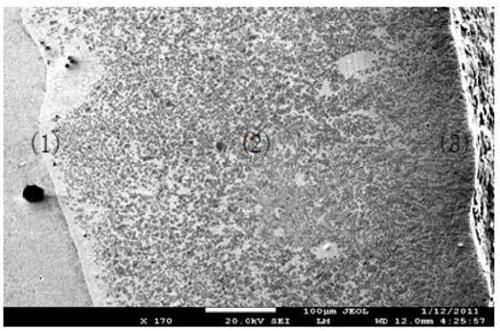

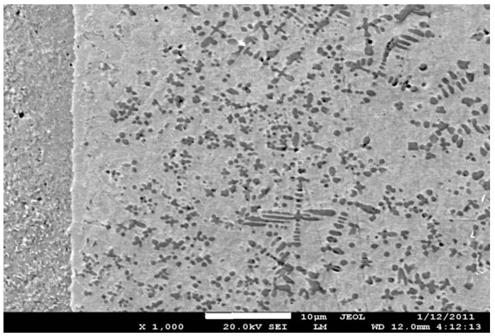

[0063] The cladding powder is Ti powder and C powder. Mix Ti powder and C powder in a molar ratio of 1:1 to form cladding powder, and grind them evenly in a ball mill. After that, use shellac alcohol soluti...

Embodiment 2

[0070] A TiC ceramic reinforced iron-based composite material was obtained in the same manner as in Example 1, except that the scanning speed was changed to 1.0 mm / s during the final laser cladding treatment of the pre-coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com