Internally circulating electrolysis type ozone generation device

An ozone generating device and internal circulation technology, which is applied in the field of electrochemistry, can solve the problems of difficulty in large-scale production of electrolytic ozone generating devices, difficulty in ensuring product quality, and many water pipeline interfaces, and achieves simple structure, easy standardization, and extended operation. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

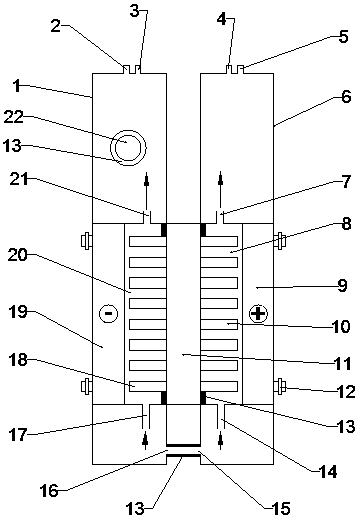

[0034] Such as figure 1 As shown, an internal circulation electrolytic ozone generator includes a cathode water tank and an anode water tank that can be bonded together.

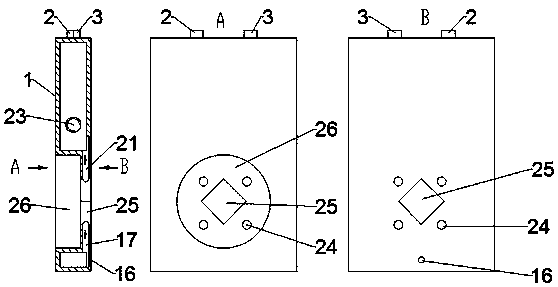

[0035] Such as figure 2 As shown, the lower part of the cathode water tank has an opposite cavity. The cavity is a trapezoidal structure and is composed of a slightly smaller cathode electrolysis cavity and a slightly larger cathode end plate cavity. The bottom of the cathode electrolysis cavity passes through the wall of the cathode water tank. The cathode water inlet hole of the cathode water tank is communicated with the inside of the cathode water tank, and the top is communicated with the inside of the cathode water tank through the cathode water / air outlet hole on the wall of the cathode water tank.

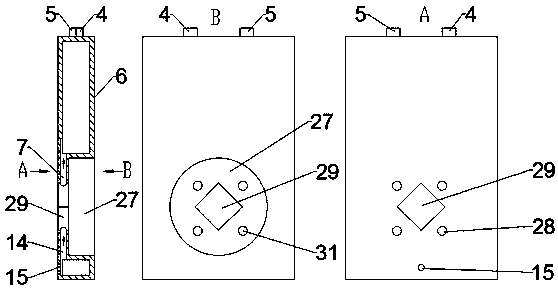

[0036] Such as image 3 As shown, the lower part of the anode water tank has an opposite cavity. The cavity is a trapezoidal structure, which is composed of a slightly smaller anode electrolysis cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com