Softener capable of imparting strength to fabric

A technology of softener and bone strength, applied in the field of softener, can solve problems such as unstructured appearance, unsatisfactory vision, loss of sense of class, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of softening agent that can make fabric have bone strength, its raw material comprises: multi-component modified silicone oil, octamethyltetrasiloxane, and its production method comprises the following steps:

[0021] Step (1): Fully mix and stir the multi-component modified silicone oil and octamethyltetrasiloxane according to the mass ratio of 1:30;

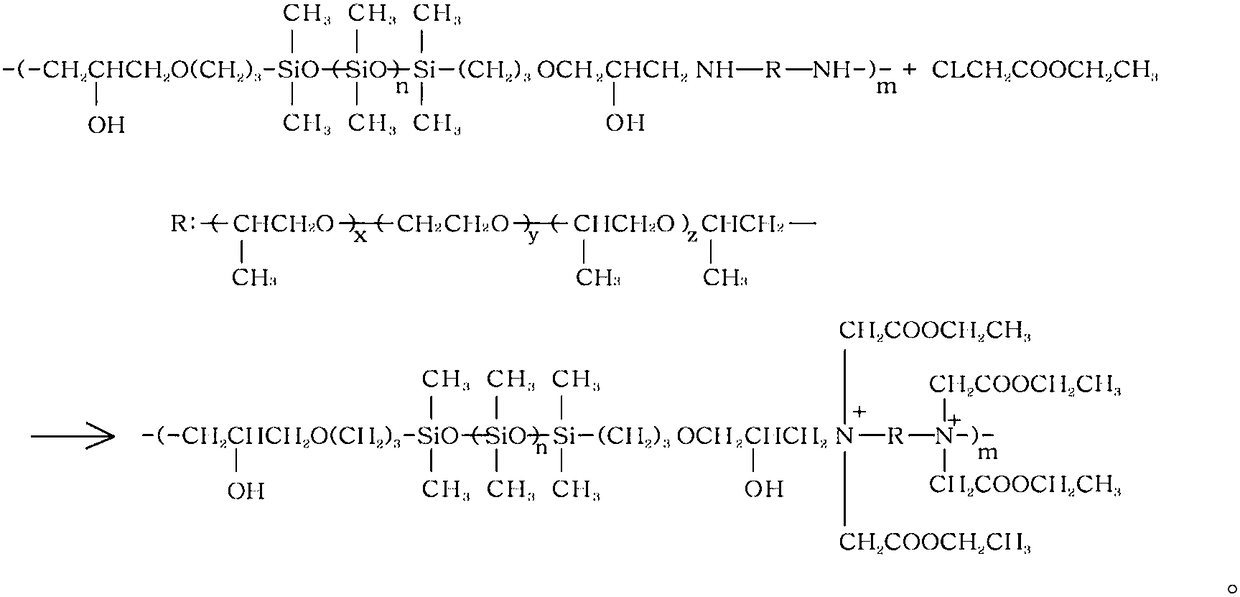

[0022] Step (2): Heat up the mixed multi-component modified silicone oil and octamethyltetrasiloxane to 120°C and keep it warm for 3 hours. The reaction method of multi-component modified silicone oil and octamethyltetrasiloxane is as follows:

[0023]

[0024] Step (3): Cool the raw materials in step (2) to 65°C, and measure the viscosity to 4000r / min;

[0025] Step (4): adding glacial acetic acid to adjust the acidity, stirring for 40 minutes, and adjusting the pH value to 5-6.5;

[0026] Step (5): Add defoamer and stir for 5 minutes to eliminate the air bubbles in the material, and then the material can be ...

Embodiment 2

[0028] A kind of softening agent that can make fabric have bone strength, its raw material comprises: multi-component modified silicone oil, octamethyltetrasiloxane, and its production method comprises the following steps:

[0029] Step (1): Fully mix and stir the multi-component modified silicone oil and octamethyltetrasiloxane according to the mass ratio to 20:1;

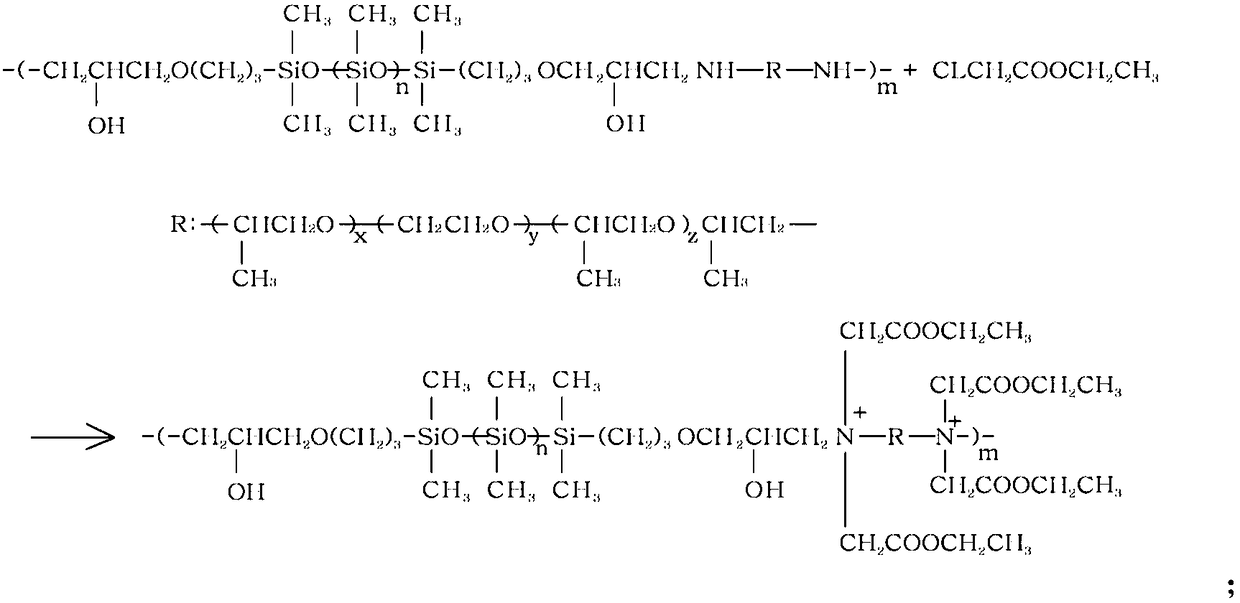

[0030] Step (2): Heat up the mixed multi-component modified silicone oil and octamethyltetrasiloxane to 120°C and keep it warm for 3 hours. The reaction method of multi-component modified silicone oil and octamethyltetrasiloxane is as follows:

[0031]

[0032] Step (3): Cool the raw materials in step (2) to 65°C, and measure the viscosity to 4000r / min;

[0033] Step (4): adding glacial acetic acid to adjust the acidity, stirring for 40 minutes, and adjusting the pH value to 5-6.5;

[0034] Step (5): Add defoamer and stir for 30 minutes to eliminate air bubbles in the material, and then the material can be dis...

Embodiment 3

[0036] A kind of softening agent that can make fabric have bone strength, its raw material comprises: multi-component modified silicone oil, octamethyltetrasiloxane, and its production method comprises the following steps:

[0037] Step (1): Fully mix and stir the multi-component modified silicone oil and octamethyltetrasiloxane according to the mass ratio of 1:30;

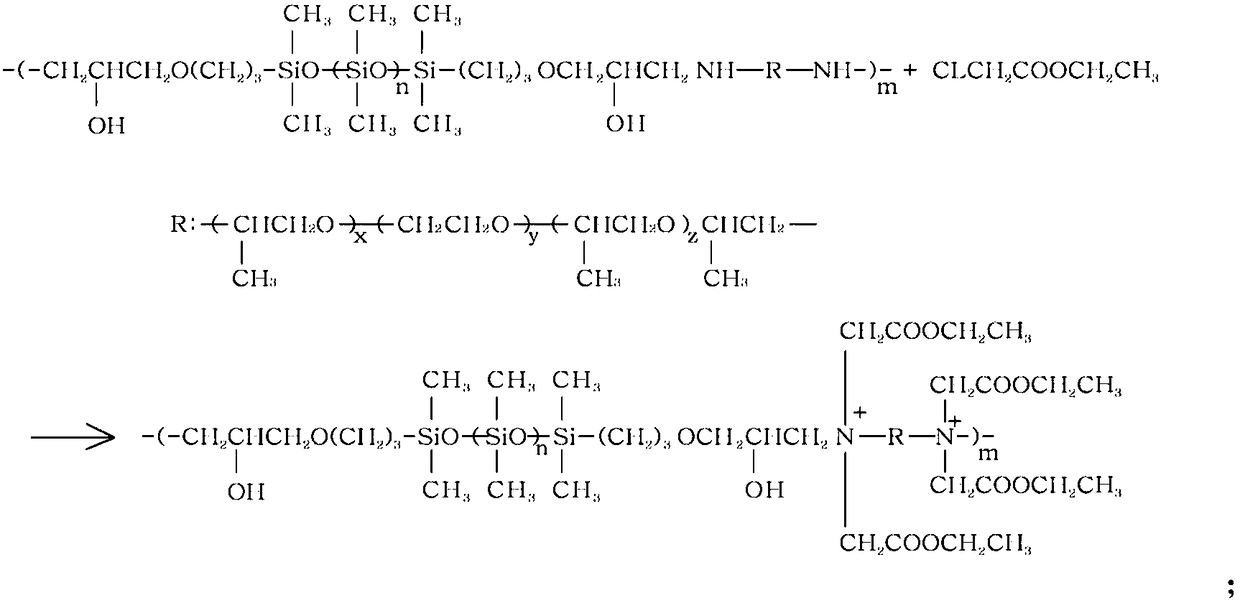

[0038] Step (2): Heat up the mixed multi-component modified silicone oil and octamethyltetrasiloxane to 120°C and keep it warm for 3 hours. The reaction method of multi-component modified silicone oil and octamethyltetrasiloxane is as follows:

[0039]

[0040] Step (3): Cool down the raw material in step (2) to 65°C, and measure the viscosity to 4000r / min;

[0041] Step (4): add glacial acetic acid to adjust the acidity, stir for 20 minutes, and adjust the pH value to 5-6.5;

[0042] Step (5): Add defoamer and stir for 5 minutes to eliminate air bubbles in the material, and then the material can be discharged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com