Oxygen-containing coal bed gas low-temperature rectification system and method capable of avoiding explosion limits

A low-temperature rectification and explosion limit technology, which is used in liquefaction, solidification, cold treatment and separation, etc., can solve problems such as reducing the safety of rectification towers, and achieve the effect of avoiding explosion limit and perfect functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

[0019] Examples.

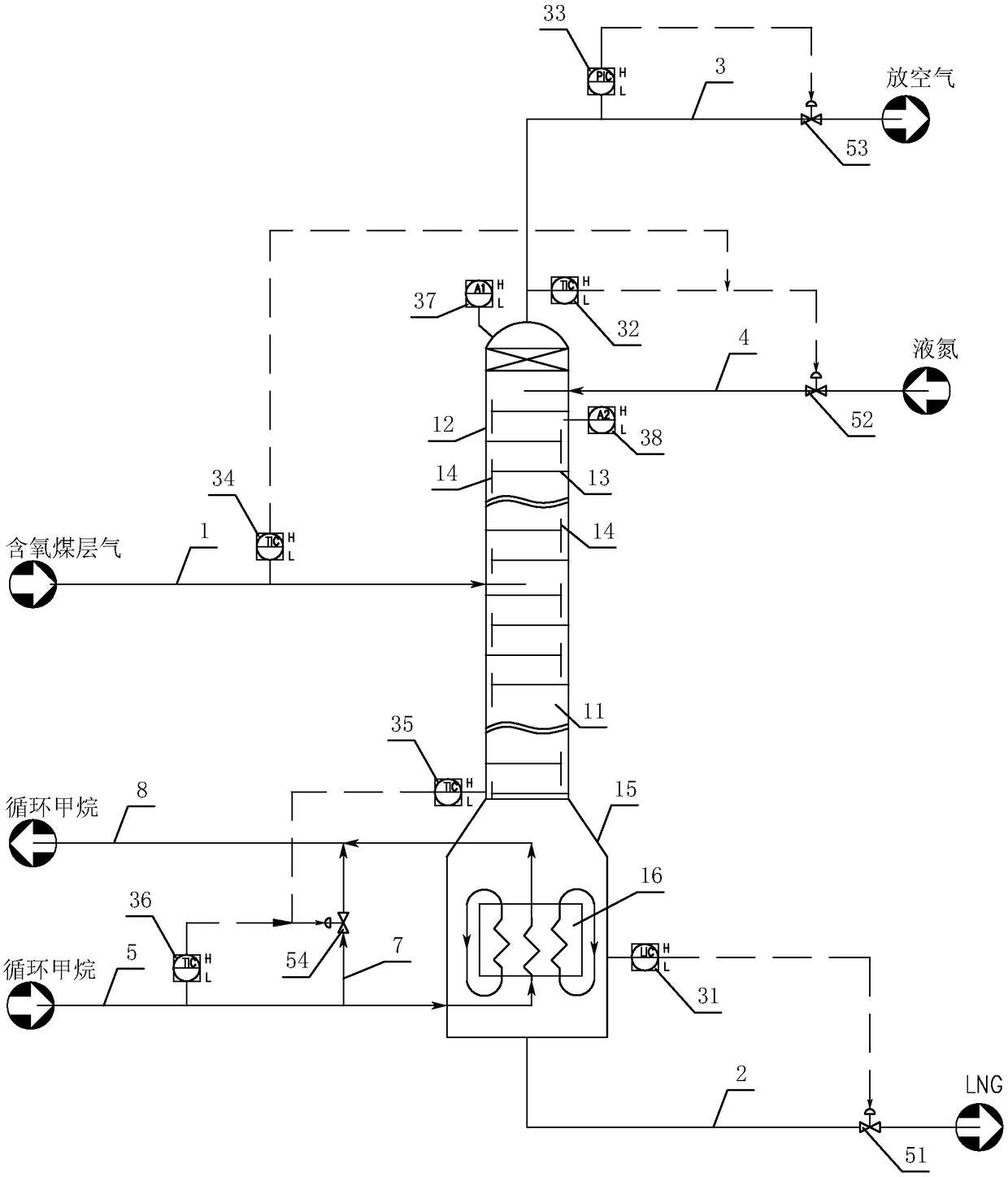

[0020] See figure 1 .

[0021] This embodiment is an oxygen-containing coalbed methane cryogenic rectification system that avoids the explosion limit, including a rectification tower 11, a reboiler 16, a coalbed methane input pipeline 1, a liquid nitrogen input pipeline 4, a circulating methane pipeline, Exhaust pipe 3 and liquid methane output pipe 2.

[0022] In this embodiment, the rectification tower 11 is a plate tower, including a tower body 12 and a tower base cavity 15 located at the bottom of the tower body 12 and used to collect liquid. The tower body 12 is provided with a number of trays 13 from top to bottom. The top one is the first tray, and the other trays are sorted from top to bottom. An overf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com