Method for representation of surface and interface characteristics of azide polyether elastomer

A technology of interface characteristics, nitrogen polyether, applied in the direction of surface/boundary effect, measurement device, instrument, etc., can solve the big difference between HTPB and NEPE propellant, lack of quantitative characterization method of azide polyether propellant, filler-matrix interface The mechanism of action is difficult to determine and other problems, to achieve the effect of easier instrument conditions, less error in test data, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

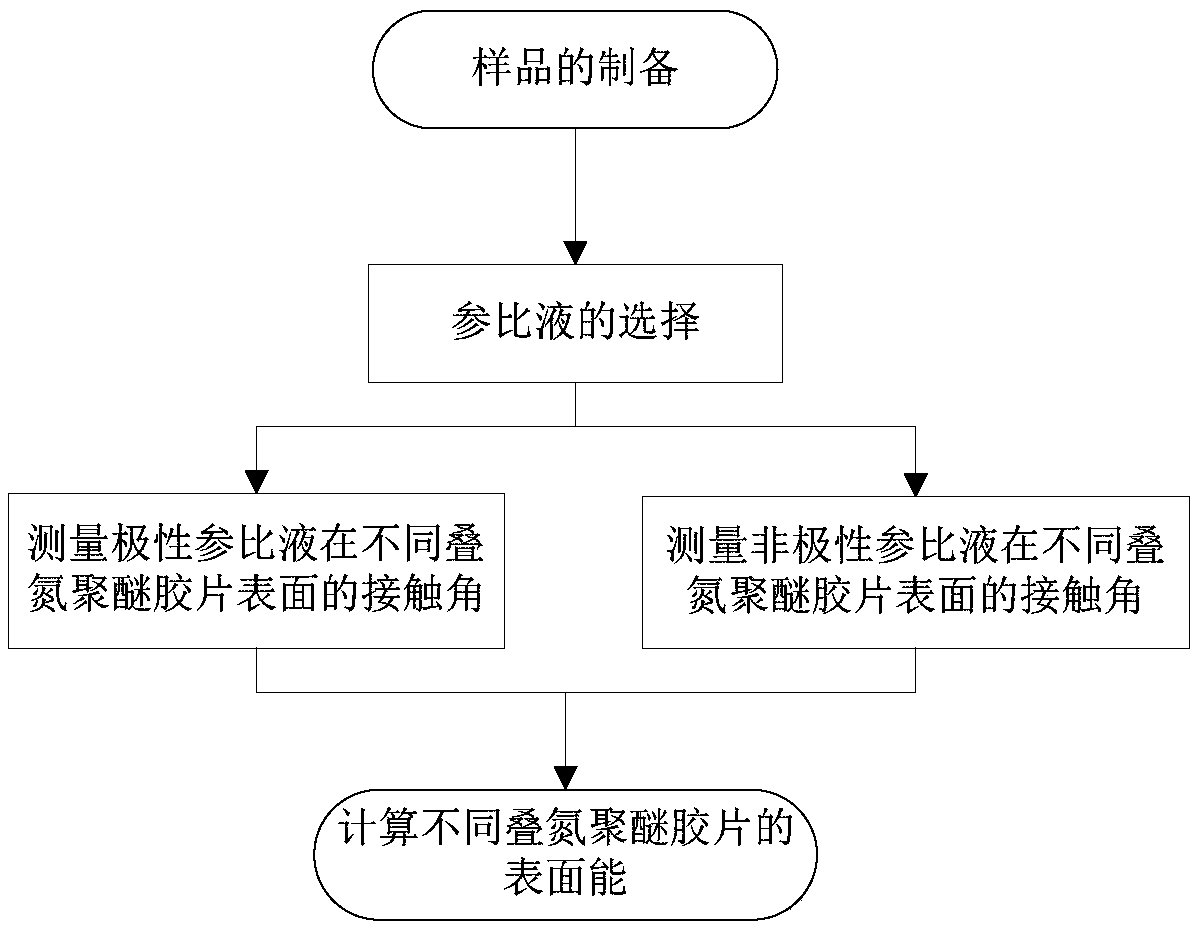

[0013] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention.

[0014] Select the appropriate parameters of the azide polyether system, add different single-component solid fillers (AP, RDX, HMX, aluminum powder) to the azide polyether system, and adopt the conventional solid propellant production process. Mixing, pouring, vacuuming, curing and other processes to prepare azide polyether films containing different fillers.

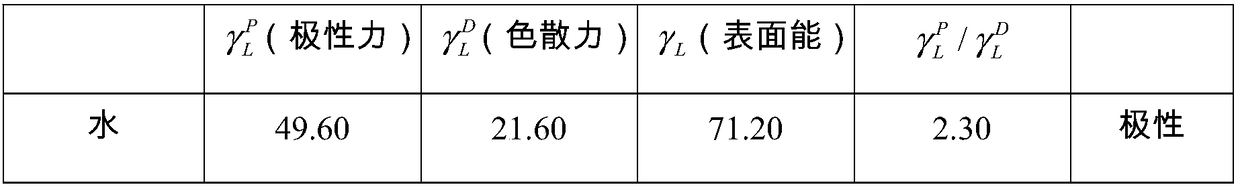

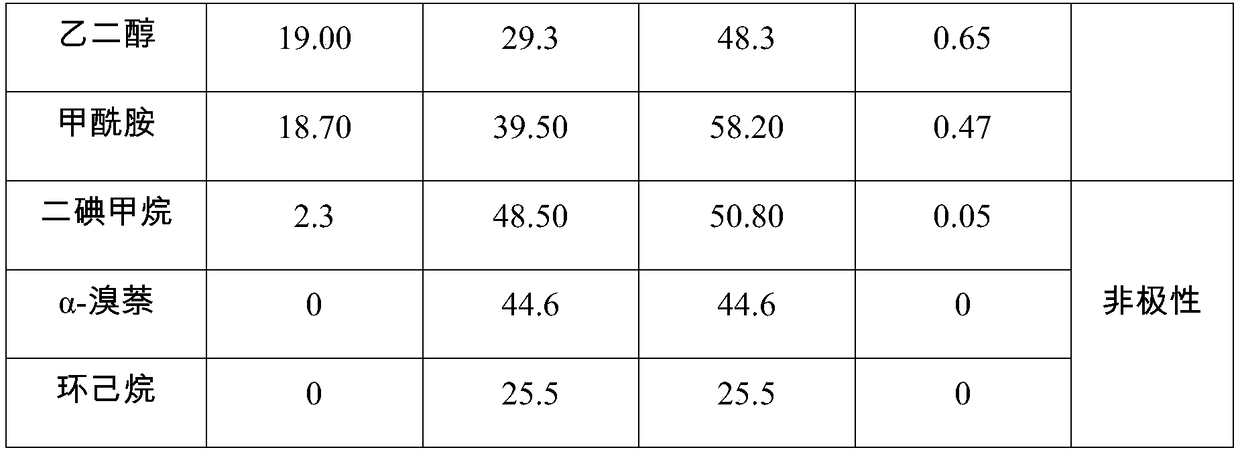

[0015] In order to reduce the maximum relative error of the surface energy of the solid material as much as possible, the reference liquid of the present invention selects three kinds of polar reference liquids and three kinds of non-polar reference liquids, which are respectively water, ethylene glycol, formamide polar reference liquid Ratio liquid, diiodomethane, α-bromonaphthalene, cyclohexane non-polar reference liquid. The surface characteristics and component data o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com