High-resolution Barkhausen noise and incremental permeability scanning imaging system

An incremental permeability, high-resolution technology, used in permeability measurement, material analysis, measurement devices, etc. The structure is not suitable for problems such as small-sized ferromagnetic blocks or magnetic thin-film materials, so as to achieve the effect of improving spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and beneficial effect of the present invention clearer, the following will further describe in detail the embodiments of the present invention in conjunction with the accompanying drawings.

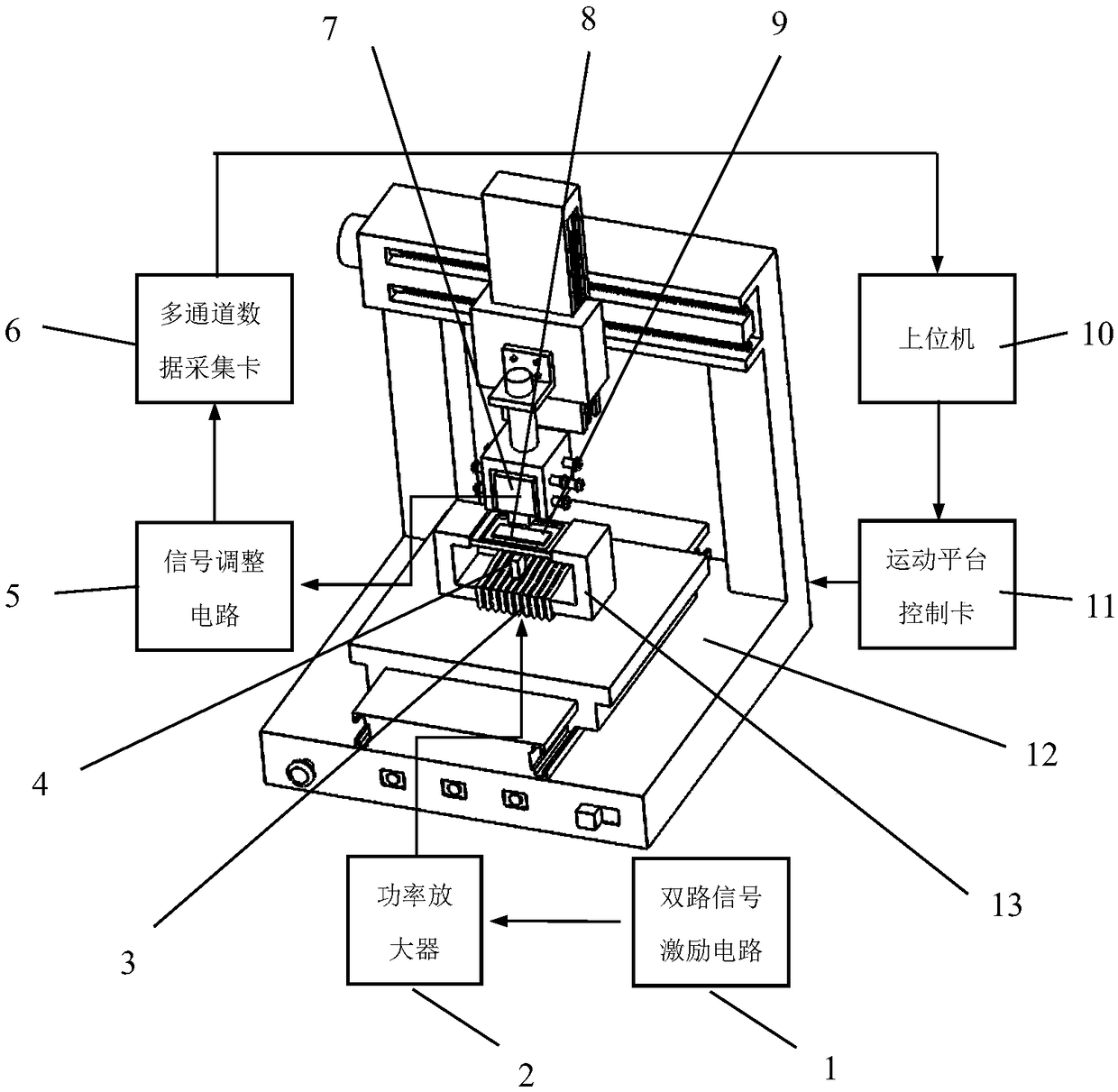

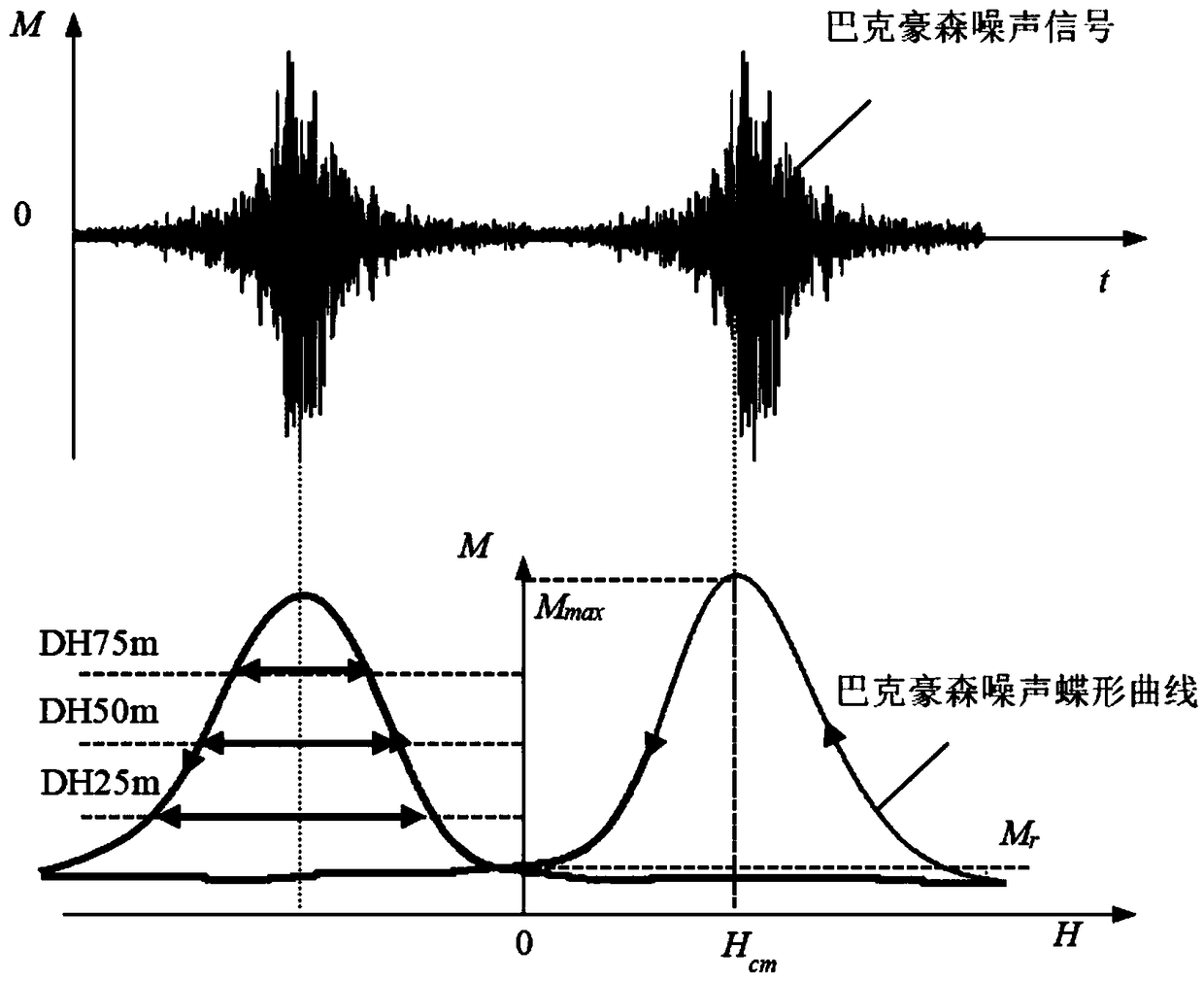

[0017] like figure 1 Connect the devices as shown. The two-way signal excitation circuit 1 generates a low-frequency sinusoidal excitation signal (0.5-200 Hz), which is output to the excitation coil 3 through the power amplifier 2, and the generated alternating magnetic field is coupled to the object placed in the stage 9 through the excitation core 13. On the surface of the test piece 8, the Hall element 4 fixedly placed on the lower surface of the material to be tested detects the tangential magnetic field intensity signal.

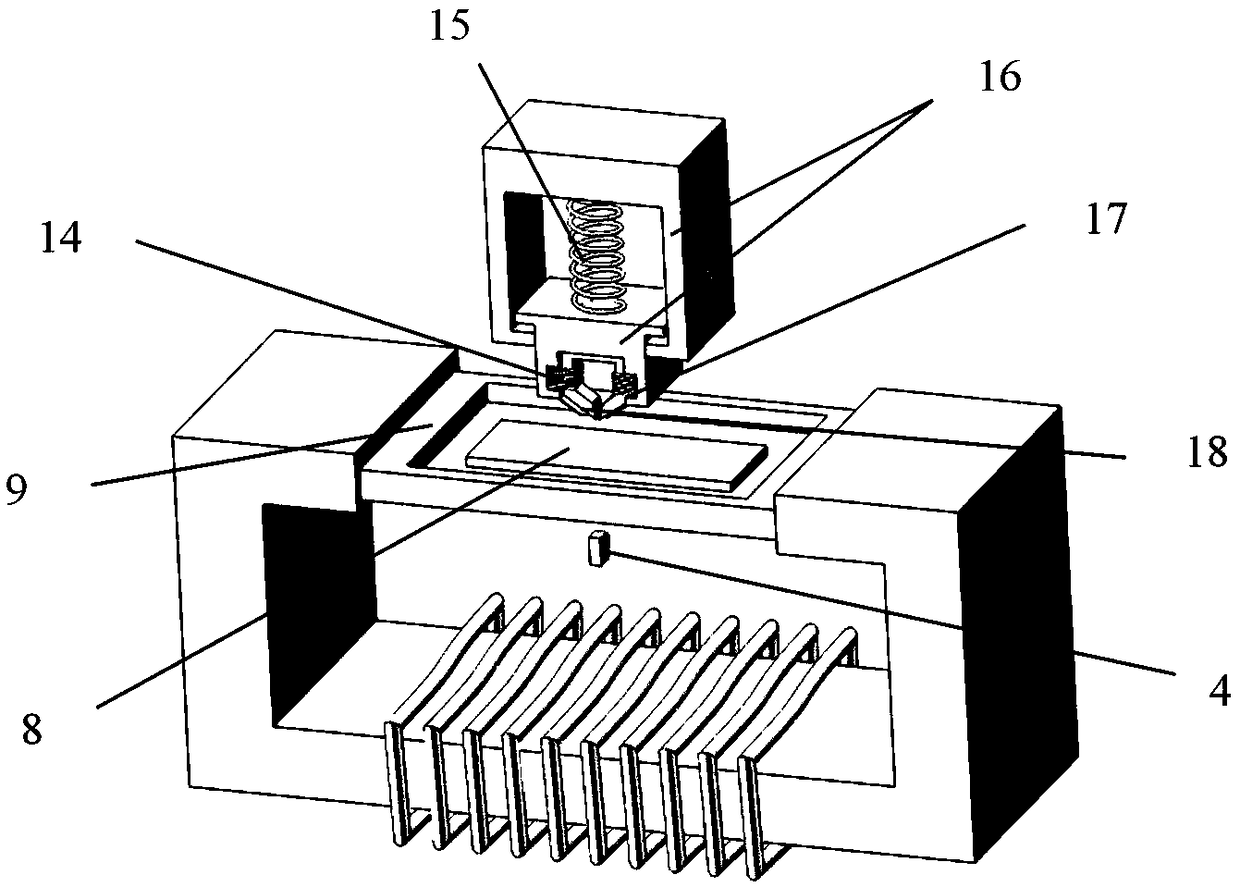

[0018] Magnetic head 7 is mainly made up of induction coil 17, detection coil 14, magnetic core 18, spring 15 and sensor housing 16 (as figure 2 As shown), the magnetic head 7 is closely attached to the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com