Method for separating positive pole piece from active substance of lithium ion battery

A lithium-ion battery and positive pole piece technology, which is applied in battery recycling, solid waste removal, waste collector recycling, etc., can solve the problem of high energy consumption, achieve the effect of reducing the amount of separation and improving washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

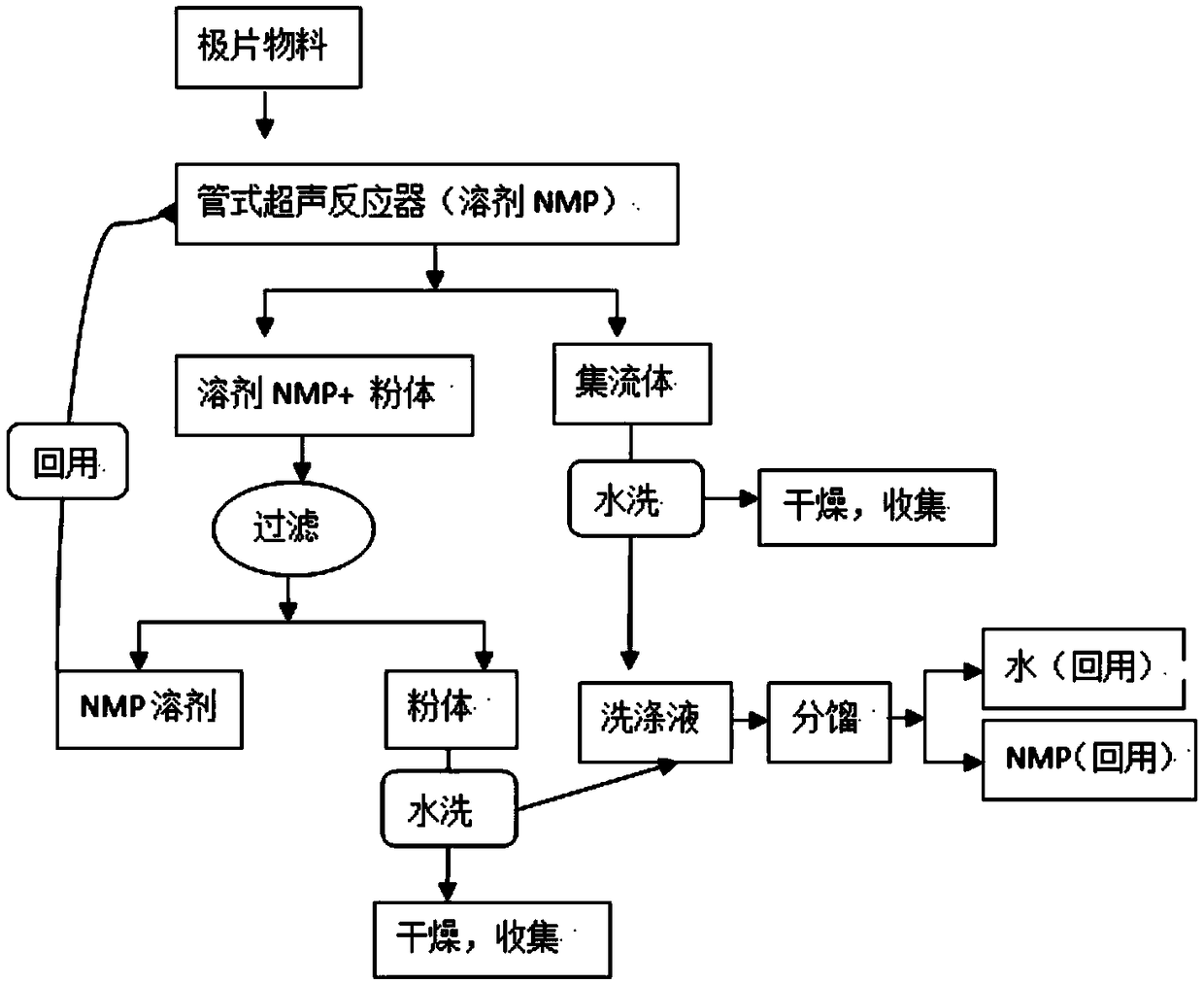

[0034] A method for separating the positive electrode sheet and the active material of a lithium ion battery. First, the positive electrode sheet material is sent into a tubular dissolver provided with an ultrasonic probe, and an organic solvent A is added for dissolution to obtain a first solution; wherein, The organic solvent A can be N-methyl-2-pyrrolidone; the solid-liquid ratio in the tubular dissolver=1g:0.5mL, the dissolution conditions of the tubular dissolver are: the temperature is 80°C; the dissolution time is 0.5 hours; filter the first solution with a filter press to obtain a current collector and a suspension, and filter the suspension to obtain a filtrate and a powder; filter the current collector and the powder with a low boiling point solvent The fractional washing was carried out three times respectively, and the low boiling point solvent was water. The washing liquid and solid matter are obtained, and the obtained solid matter is dried and collected, wherein...

Embodiment 2

[0036] A method for separating the positive electrode sheet and the active material of a lithium ion battery. First, the positive electrode sheet material is sent into a tubular dissolver provided with an ultrasonic probe, and an organic solvent A is added for dissolution to obtain a first solution; wherein, The organic solvent A can be dimethylformamide; the solid-liquid ratio in the tubular dissolver=1g:1.5)mL, and the dissolution conditions of the tubular dissolver are: the temperature is 50°C; the dissolution time is 2 hours ; The first solution is filtered with a filter press to obtain a current collector and a suspension, and the suspension is filtered to obtain a filtrate and a powder; the current collector and the powder are respectively treated with a low boiling point solvent The fractional washing was carried out three times, and the low boiling point solvent was ethanol. The washing liquid and solid matter are obtained, and the obtained solid matter is dried and co...

Embodiment 3

[0038] A method for separating the positive electrode sheet and the active material of a lithium ion battery. First, the positive electrode sheet material is sent into a tubular dissolver provided with an ultrasonic probe, and an organic solvent A is added for dissolution to obtain a first solution; wherein, The organic solvent A can be dimethylacetamide; the solid-liquid ratio in the tubular dissolver=1g:1mL, and the dissolution conditions of the tubular dissolver are: the temperature is 60° C.; the dissolution time is 1 hour; The first solution is filtered with a filter press to obtain a current collector and a suspension, and the suspension is filtered to obtain a filtrate and a powder; the current collector and the powder are respectively graded and washed with a low boiling point solvent Three times, the low boiling point solvent was diethyl ether. The washing liquid and solid matter are obtained, and the obtained solid matter is dried and collected, wherein, during three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com