Processing method of scallion-flavor chicken essence

A processing method and technology of chives, applied in the direction of food ingredients as odor improvers, food science, food ingredients as color, etc., can solve the problems of limited production, large particle size, loss of fresh and fresh fragrance of chives, etc., to achieve Improved taste and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

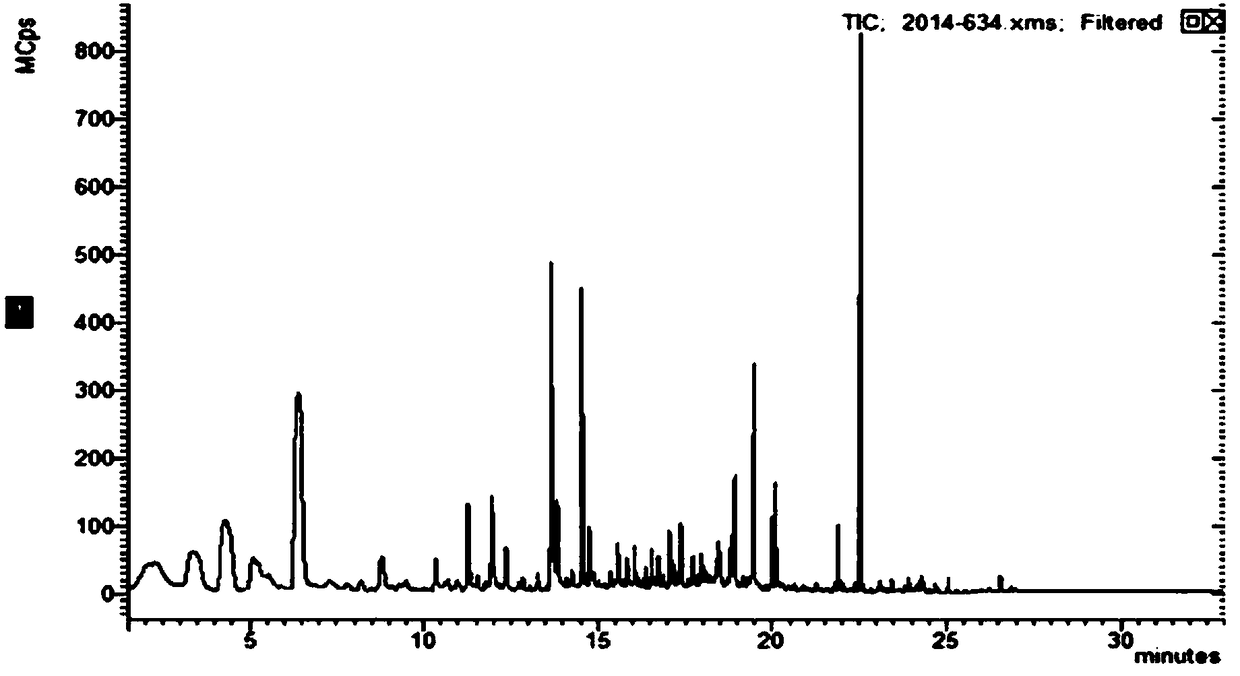

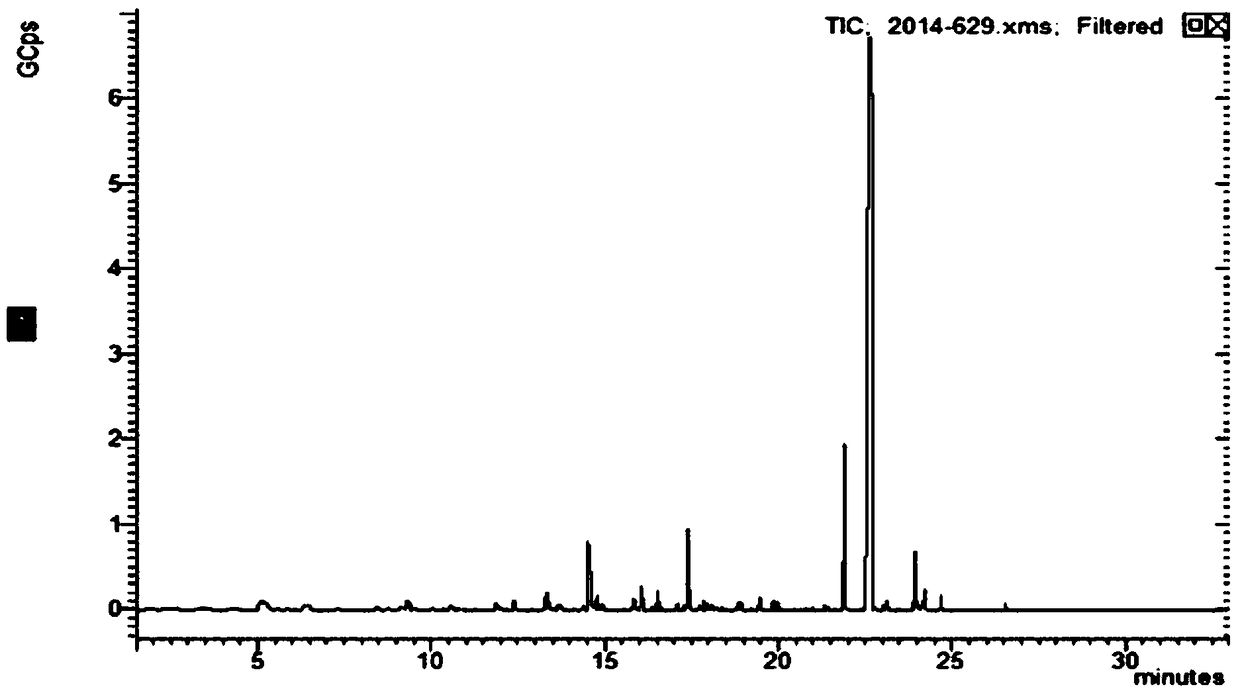

Image

Examples

Embodiment 1

[0026] Example 1: Preparation and detection of savory chicken essence with chives

[0027] The preparation of scallion flavored chicken essence is as follows:

[0028] (1) Shallot pretreatment: select fresh shallots, wash them, drain the water, remove the shallots, and cut them into sections. Blanch at 100°C for 30s, soak in 0.3% sodium carbonate lye for 10 minutes, soak in 0.03% zinc chloride and 0.2% calcium chloride solution for 30 minutes, inactivate enzymes and protect the color of shallots, and drain.

[0029] (2) Vacuum drying of shallots: the pretreated shallots are vacuum-dried at a drying temperature of 60° C., a drying time of 10 h, and a vacuum degree of 8.5-8.9 kPa. After drying, pulverize with a plant pulverizer to obtain vacuum-dried shallot powder;

[0030] (3) Preparing chive and savory chicken essence according to the formula: the formula is as follows in parts by weight: 4-6 parts of white sugar; 1-3 parts of starch; chicken powder (Guangdong Jiahao Food C...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap