Polyurethane paint and preparation method thereof

A polyurethane and paint technology, applied in polyurea/polyurethane coatings, polyester coatings, coatings, etc., can solve problems such as poor yellowing resistance, achieve good yellowing resistance, strong climate adaptability, and bright paint film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

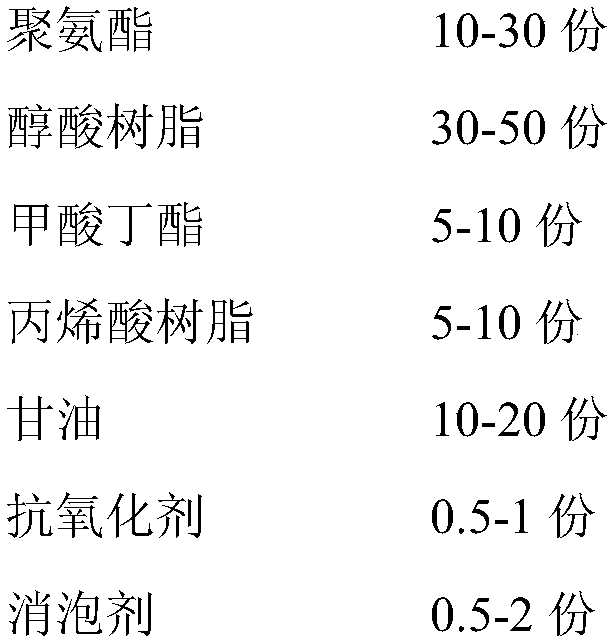

[0025] Described polyurethane paint is made from the raw materials of following parts by weight:

[0026]

[0027] The thickener is hydroxypropylmethylcellulose and hydroxyethylcellulose, and the mass ratio is 2:1.

[0028] The silicone leveling agent is BYK-310.

[0029] Its preparation method is as follows:

[0030] (1) Add butyl formate and glycerin to the reaction kettle, add polyurethane, alkyd resin and acrylic resin, adjust the stirring speed to 650r / min, and stir for 4min;

[0031] (2) Add dibutyl hydroxytoluene, octylphenol polyoxyethylene ether, thickener, and leveling agent, adjust the rotation speed to 1100r / min, and stir for 13 minutes to obtain the product.

Embodiment 2

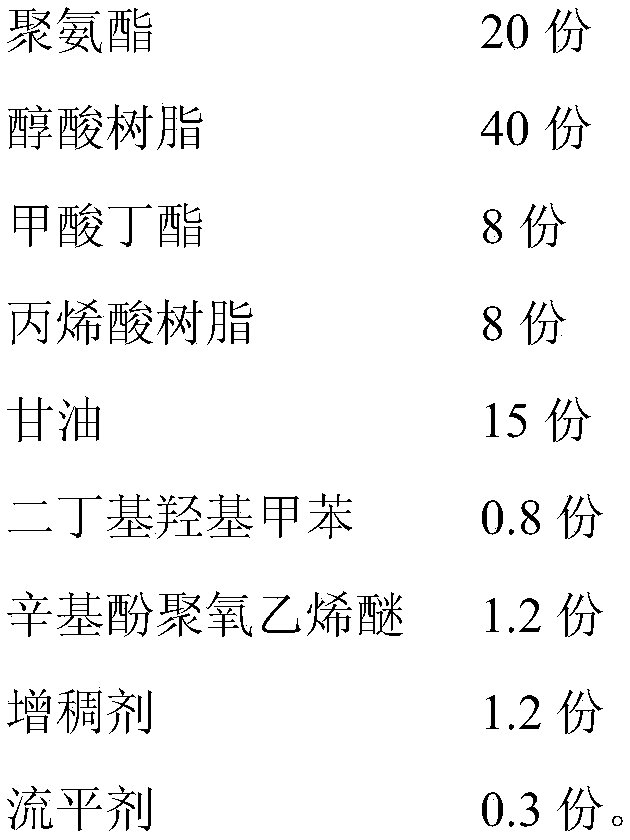

[0033] Described polyurethane paint is made from the raw materials of following parts by weight:

[0034]

[0035] The thickener is hydroxypropylmethylcellulose and hydroxyethylcellulose, and the mass ratio is 2:1.

[0036] The silicone leveling agent is BYK-310.

[0037] Its preparation method is as follows:

[0038] (1) Add butyl formate and glycerin to the reaction kettle, add polyurethane, alkyd resin and acrylic resin, adjust the stirring speed to 500r / min, and stir for 3min;

[0039] (2) Add dibutyl hydroxytoluene, octylphenol polyoxyethylene ether, thickener and leveling agent, adjust the rotation speed to 1000r / min, and stir for 10min to obtain the product.

Embodiment 3

[0041] Described polyurethane paint is made from the raw materials of following parts by weight:

[0042]

[0043]

[0044] The thickener is hydroxypropylmethylcellulose and hydroxyethylcellulose, and the mass ratio is 2:1.

[0045] The silicone leveling agent is BYK-310.

[0046] Its preparation method is as follows:

[0047] (1) Add butyl formate and glycerin to the reaction kettle, add polyurethane, alkyd resin and acrylic resin, adjust the stirring speed to 800r / min, and stir for 5min;

[0048] (2) Add dibutyl hydroxytoluene, octylphenol polyoxyethylene ether, thickener, and leveling agent, adjust the rotation speed to 1200r / min, and stir for 15 minutes to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com