Preparation method of composite graphite bipolar plate

A technology of composite graphite and bipolar plates, which can be used in flat products, final product manufacturing, sustainable manufacturing/processing, etc., and can solve problems such as insufficient mechanical strength, brittle graphite plates, and proportional contradictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

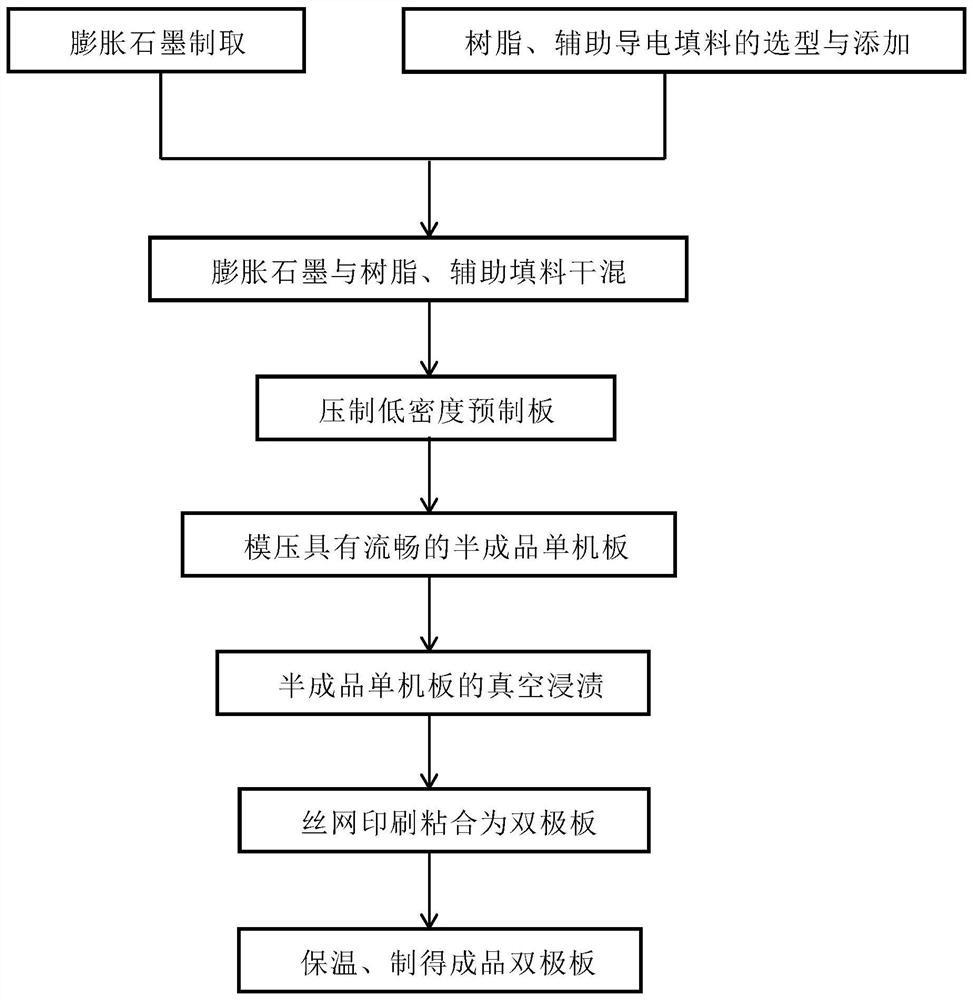

[0026] The present application provides a method for preparing a composite graphite bipolar plate. The method of the present application comprises the following steps: 1. prepare expanded graphite from graphite ore; 2. mix selected resin and auxiliary conductive filler to obtain a mixture of resin and auxiliary conductive filler, which is recorded as the first mixture; 3. prepare the The mixture of expanded graphite, resin and auxiliary conductive filler is uniformly mixed by dry mixing, and is recorded as the second mixture; ④ Press the second mixture into a low-density prefabricated board; ⑤ The low-density prefabricated board is molded into a The unipolar plate of the field, wherein the unipolar plate includes a hydrogen flow field unipolar plate and an oxygen flow field unipolar plate; ⑥ the unipolar plate is vacuum impregnated; ⑦ the hydrogen flow field unipolar plate is mixed with oxygen The flow field unipolar plate is bonded with an adhesive (by molding) by screen prin...

Embodiment 1

[0074] 1) Take 2000g of graphite ore raw material and expand it instantly in a high-temperature furnace at 1050°C until the expansion volume reaches 180ml / g, and the expansion multiple is 270 times. It is shaped by a graphite shaping machine, and the shaping time is 10-15 minutes. After shaping, the long diameter of the expanded graphite is reduced by 40-50%.

[0075] 2) dry-blending 60 wt% of phenolic resin powder meeting the particle size requirement after grinding and sieving with 40 wt% of carbon black / carbon fiber, and mixing uniformly to obtain the first mixture.

[0076] 3) Proportionally mix the first mixture with the existing expanded graphite in an appropriate proportion, wherein the expanded graphite is 50wt%; the mixing time is 10-30min with a mixer to prepare the second mixture.

[0077] 4) Continue to add 8wt% acicular ore powder to the mixture of expanded graphite, phenolic resin, and carbon black / carbon fiber. In this example, calcite powder is used. The averag...

Embodiment 2

[0085] 1) Take 2000g of graphite ore raw material and expand it instantly in a high-temperature furnace at 1200°C until the expansion volume reaches 200ml / g, and the expansion factor is 300 times. It is shaped by a graphite shaping machine, and the shaping time is 10-15 minutes. After shaping, the long diameter of the expanded graphite is reduced by 40-50%.

[0086] 2) Dry-blending the epoxy resin powder (65wt%) meeting the particle size requirements after grinding and sieving with the mesophase carbon microspheres (35wt%), and mixing uniformly to prepare the first mixture.

[0087] 3) Proportionally mix the first mixture with an appropriate proportion and the existing expanded graphite, wherein the expanded graphite is 70wt%, and the mixing time is 10-30min with a mixer to prepare the second mixture.

[0088] 4) Continue to add 7wt% acicular ore powder to the mixture of expanded graphite, phenolic resin, and carbon black / carbon fiber. In this example, calcite powder is used. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com