An ethylene cracking furnace

A technology of ethylene cracking furnace and furnace tube, which is applied in the direction of cracking, hydrocarbon cracking to hydrocarbon, non-catalytic thermal cracking, etc. It can solve the problems of difficult elimination and furnace tube bending, and achieve the effects of avoiding bending, simple connection and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

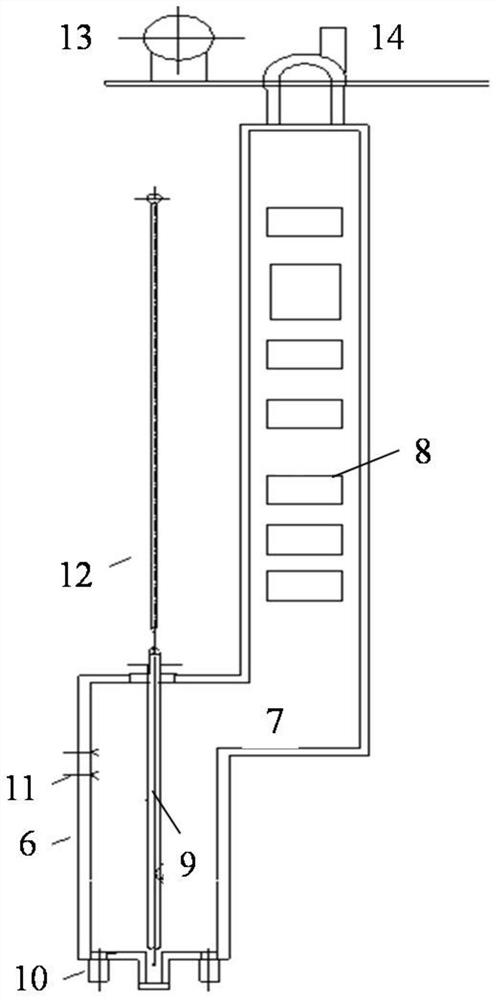

[0065] The invention provides an ethylene cracking furnace, such as figure 1 As shown, the ethylene cracking furnace includes: at least one radiant section 6, a convection section 8, a transition section 7 between the radiant section and the convection section, a quench boiler 12, a high-pressure steam drum 13 and an induced draft fan 14;

[0066] Bottom burners 10 and / or side wall burners 11 are arranged in the radiant section 6, and multiple groups of radiant furnace tubes 9 are vertically arranged;

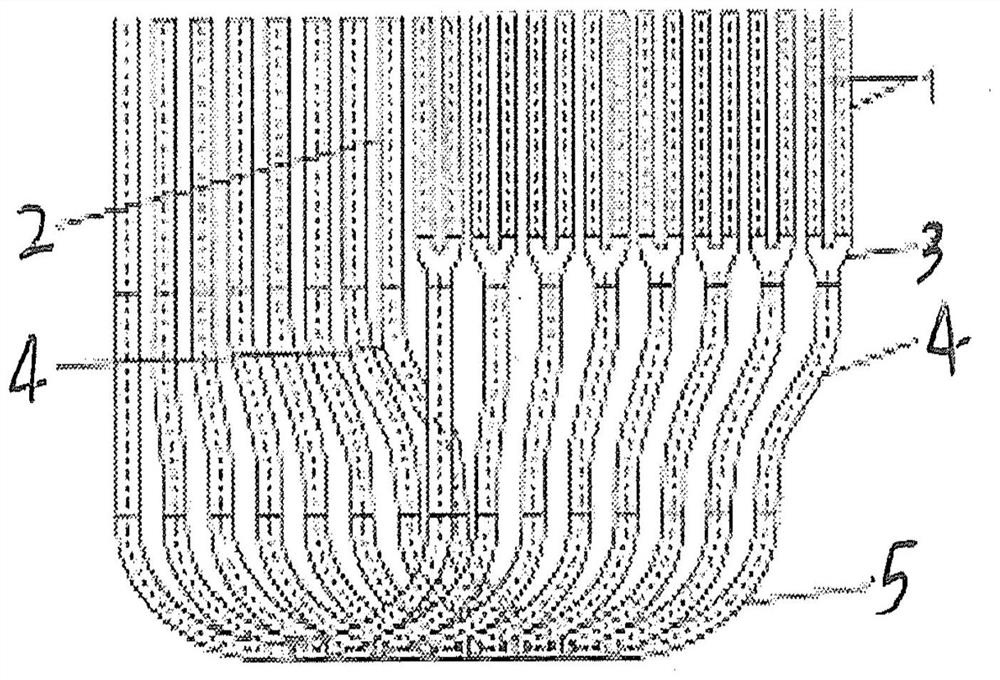

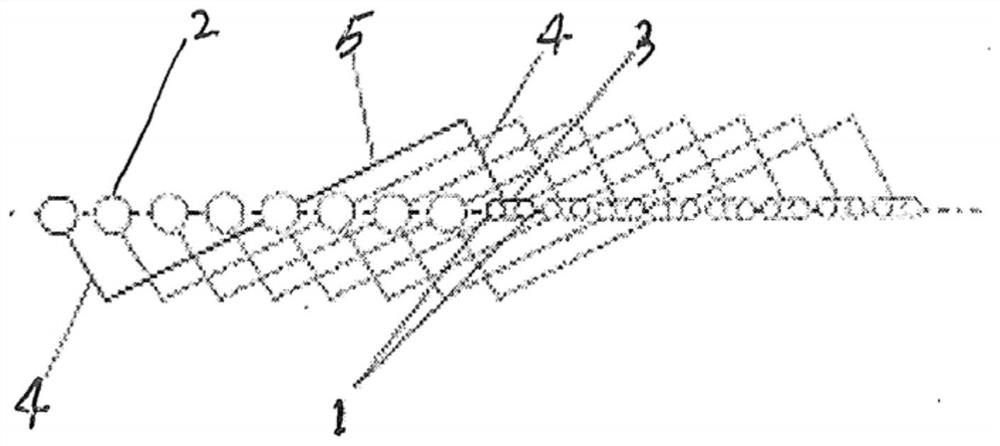

[0067] like Figure 5-1 As shown, the radiation furnace tube 9 is a two-pass 2-1 type branched and reduced-diameter radiation furnace tube, and each two-pass 2-1 type branched and reduced-diameter radiation furnace tube includes a first-pass furnace tube 1, a second-pass The furnace tube 2 and the elbow assembly formed by the symmetrical elbow 5 and the S-shaped elbow 4 connecting the first-stage furnace tube 1 and the second-stage furnace tube 2; the symmetrical elbow 5 is i...

Embodiment 2

[0072] The present invention also provides a kind of ethylene cracking furnace, such as figure 1 As shown, the ethylene cracking furnace includes: at least one radiant section 6, a convection section 8, a transition section 7 between the radiant section and the convection section, a quench boiler 12, a high-pressure steam drum 13 and an induced draft fan 14;

[0073] Bottom burners 10 and / or side wall burners 11 are arranged in the radiant section 6, and multiple groups of radiant furnace tubes 9 are vertically arranged;

[0074] like Figure 6-1 As shown, the radiation furnace tube 9 is a two-pass 2-1 type branched and reduced-diameter radiation furnace tube, and each two-pass 2-1 type branched and reduced-diameter radiation furnace tube includes a first-pass furnace tube 1, a second-pass The furnace tube 2 and the elbow assembly formed by the symmetrical elbow 5 and the S-shaped elbow 4 connecting the first-stage furnace tube 1 and the second-stage furnace tube 2; the symm...

Embodiment 3

[0080] The invention provides an ethylene cracking furnace, such as figure 1 As shown, the ethylene cracking furnace includes: at least one radiant section 6, a convection section 8, a transition section 7 between the radiant section and the convection section, a quench boiler 12, a high-pressure steam drum 13 and an induced draft fan 14;

[0081]Bottom burners 10 and / or side wall burners 11 are arranged in the radiant section 6, and multiple groups of radiant furnace tubes 9 are vertically arranged;

[0082] like Figure 7-1 As shown, the radiation furnace tube 9 is a two-pass 2-1 type branched and reduced-diameter radiation furnace tube, and each two-pass 2-1 type branched and reduced-diameter radiation furnace tube includes a first-pass furnace tube 1, a second-pass The furnace tube 2 and the elbow assembly formed by the symmetrical elbow 5 and the S-shaped elbow 4 connecting the first-stage furnace tube 1 and the second-stage furnace tube 2; the symmetrical elbow 5 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com