Lithium air battery

A lithium-air battery and lithium-ion technology, applied in the direction of fuel cells, battery electrodes, hybrid battery components, etc., can solve problems such as difficult charging reactions, lack of electronic conductivity of lithium peroxide, and hinder the cycle characteristics of lithium-air batteries. Improvement of cycle characteristics and effect of lowering charge potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

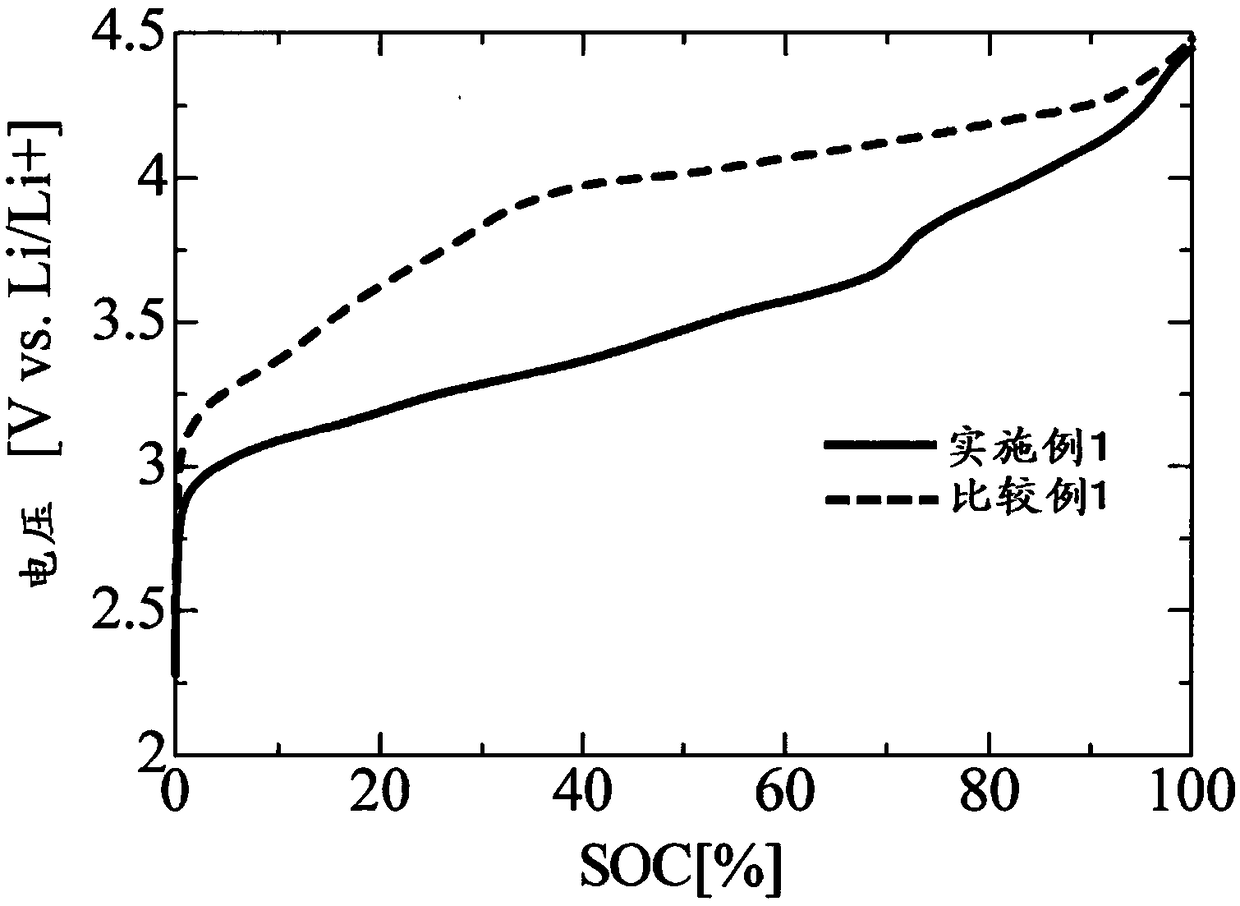

Embodiment 1

[0097] Ketjen Black (manufactured by Lion King Corporation) powder was used as the carbon material. As the binder, powder of PTFE (manufactured by Daikin Industry Co., Ltd.) was used. The carbon material, the powder of cuprous iodide (CuI), and the binder were kneaded using an ethanol solvent in a mass ratio of 40:15:10 to obtain a mixture. The mixture is rolled by rolling to produce electrode sheets. The obtained electrode sheet was cut to obtain a positive electrode (positive electrode layer).

[0098] LiTFSA (lithium bistrifluoromethanesulfonamide; manufactured by Kishida Chemical Co., Ltd.) was mixed and dissolved in tetraglyme (TEGDME; manufactured by Kishida Chemical Co., Ltd.) at a concentration of 1 mol / liter. The mixed solution is stirred for 24 hours in a dry gas atmosphere with a dew point of -50 degrees or less to obtain a non-aqueous electrolyte.

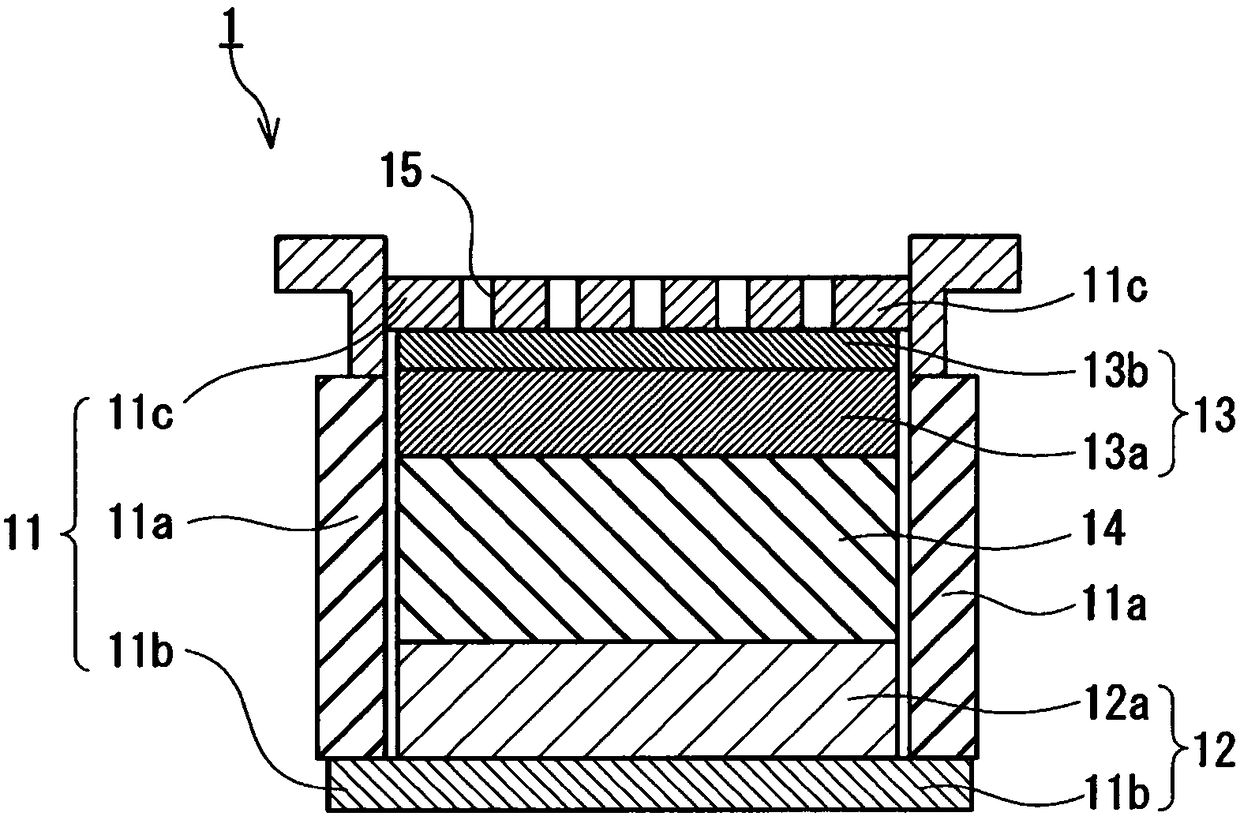

[0099] As the diaphragm, a glass fiber diaphragm is prepared. A SUS304 mesh (manufactured by Nilac Co., Ltd.) as a cur...

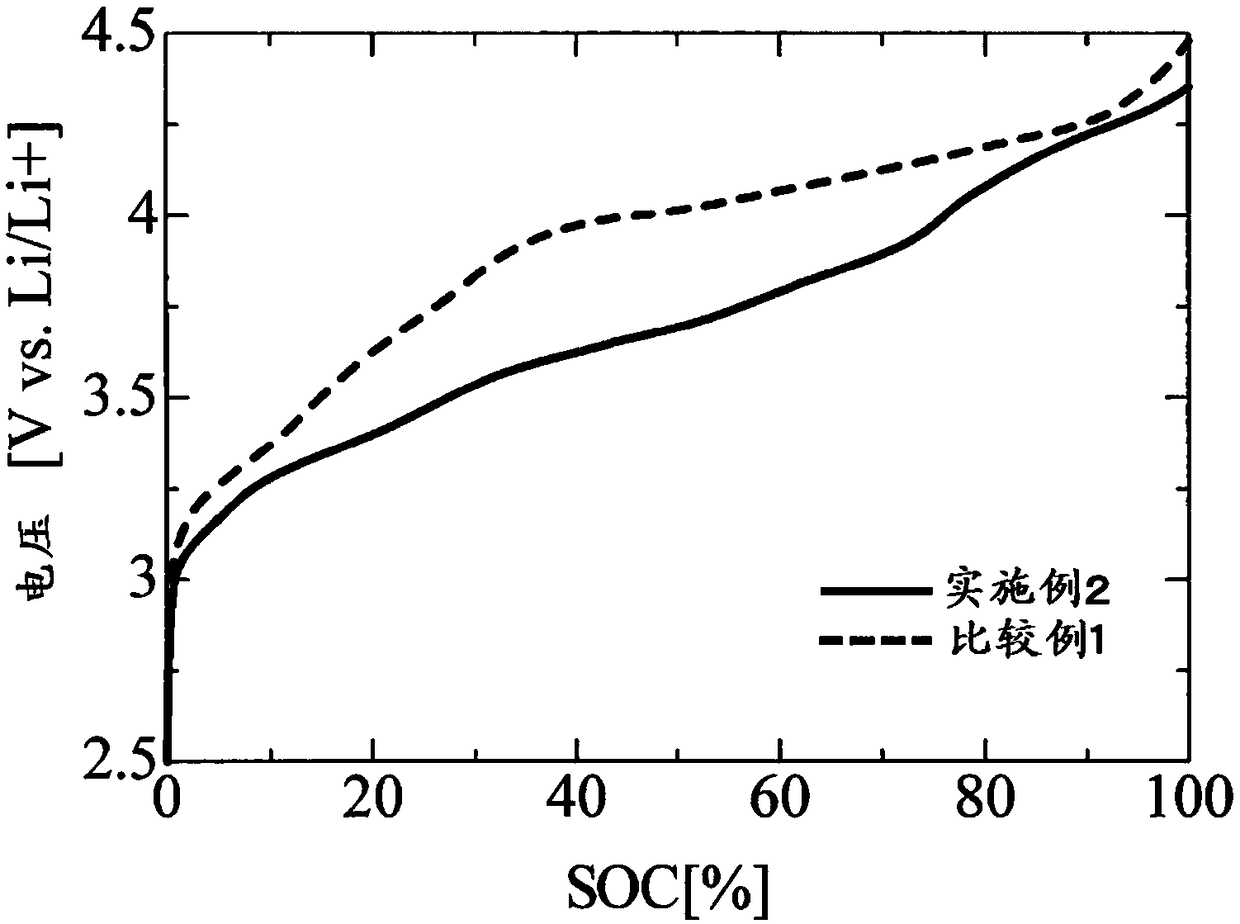

Embodiment 2

[0101] Except that CuBr powder was used instead of CuI powder, the same method as in Example 1 was used to produce a lithium air battery.

Embodiment 3

[0103] Except for using CuSCN powder instead of CuI powder, the same method as in Example 1 was used to produce a lithium air battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com