A lithium-nitrogen secondary battery electrode and lithium-nitrogen secondary battery

A secondary battery, nitrogen technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unsatisfactory nitrogen fixation product concentration, poor economy, expensive equipment and drugs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

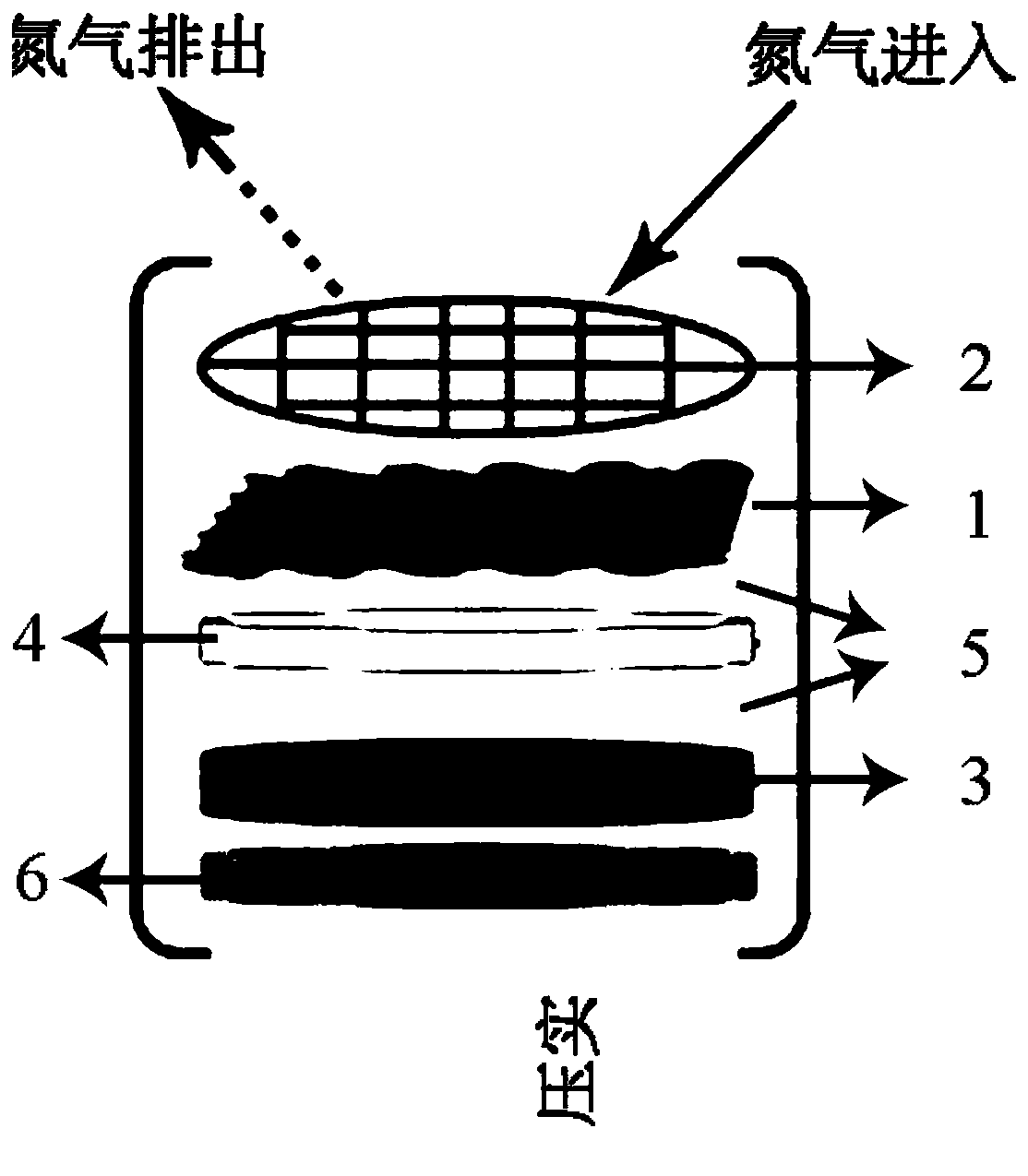

[0058] The present invention has no special limitation on the preparation process of the positive electrode of the lithium-nitrogen secondary battery. Those skilled in the art can select and adjust according to actual production conditions, raw material conditions and product requirements. The positive electrode of the lithium-nitrogen secondary battery described in the present invention The preparation process is preferably:

[0059] First, the carbon cloth is acid-activated with strong acid, washed and dried, then installed in a porous stainless steel sheet, pressed tightly, and used as the positive electrode of the battery.

[0060] In order to improve the electrochemical performance of the lithium-nitrogen secondary battery and better realize artificial nitrogen fixation, the positive electrode preferably includes an active material, or a mixed material of an active material and a binder. The active material, or the mixed material of the active material and the binder, is ...

Embodiment 1

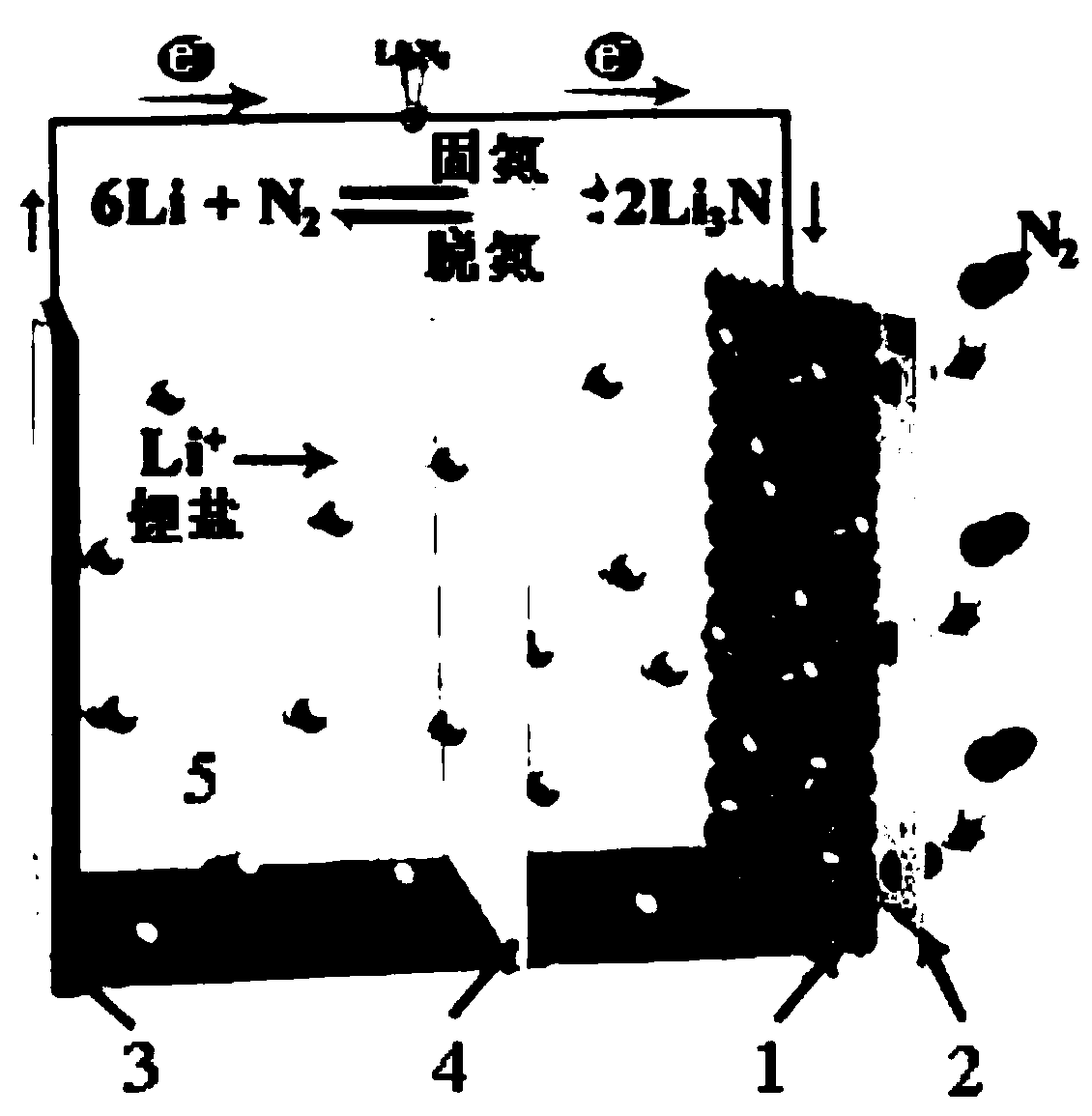

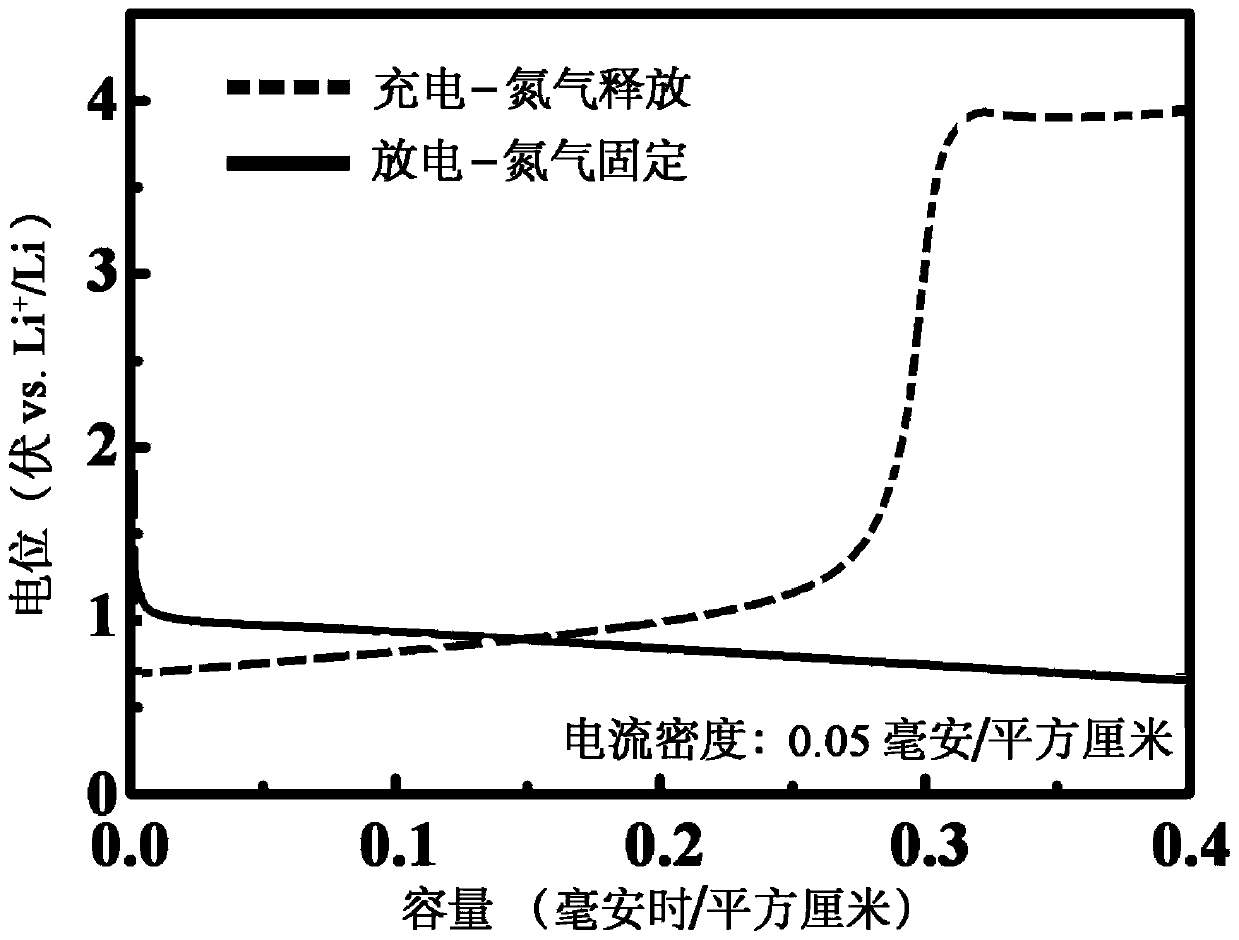

[0079] This embodiment provides a lithium-nitrogen rechargeable battery that can be used for artificial nitrogen fixation, and its structure can be referred to figure 1 As shown, the positive electrode gas (i.e. working gas) used in this embodiment is nitrogen, and the battery number of this embodiment is marked as A1, and its structure includes:

[0080] The negative electrode is composed of metal lithium sheet and stainless steel sheet;

[0081] The gas positive electrode in this embodiment is only composed of carbon cloth. The carbon cloth can act as a current collector and an active material at the same time, and provide electrons to the positive electrode gas. The working gas is nitrogen.

[0082] The electrode interstitial is located between the nitrogen positive electrode (gas positive electrode) and the lithium sheet negative electrode, which is used to isolate the working gas from the negative electrode, and at the same time enables lithium ions to conduct between the...

Embodiment 2

[0094] This embodiment provides a lithium-nitrogen rechargeable secondary battery, denoted as A2, whose structure is basically the same as that of the battery provided in Example 1, except that the structure of the gas electrode is different. The gas positive electrode in this embodiment is only composed of carbon paper. The carbon paper can simultaneously act as a current collector and an active material, and provide electrons to the positive electrode gas. The working gas is nitrogen.

[0095] The gas positive electrode in this example can be made by the following method: first place the carbon paper in a concentrated nitric acid solution at 140°C for 12 hours, then wash it three times with distilled water, absolute ethanol, and acetone, and cut the carbon paper into diameters For a 16mm wafer, dry it in a vacuum oven at 80°C for 24 hours. Finally, the dried carbon paper was placed in a porous stainless steel sheet and compressed under a pressure of 10 MPa to serve as the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com