Method for controlling brown stains of fresh-cut solanum tuberosum

A technology for fresh-cut potatoes and potatoes, which is applied in the fields of fruit and vegetable preservation, food preservation, food science, etc. It can solve the problems of difficult control of heat treatment time, change of taste of fresh-cut products, and influence on consumers' choice and consumption, etc., so as to achieve easy industrialization Operation and promotion, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Soaking treatment of potatoes in proline solutions with different concentrations: Soak potatoes in proline aqueous solutions with different concentrations (0, 30, 60, 90mmol / L) at a solution temperature of 20°C for 1 hour. Wherein 0mmol / L proline aqueous solution is clear water control group.

[0065] (2) Potato fresh-cut processing: The processed potatoes are peeled, sterilized, cut into slices (3-5mm thick), drained, and then put into polyethylene bags, and the bag mouth is folded. Store in a refrigerator at 3-5°C.

[0066] (3) Treatment of the control group: without any soaking treatment, the potatoes of the same variety and batch were peeled, sterilized, cut into slices (3-5mm thick), drained, and then put into polyethylene bags with the mouth folded. Store in a refrigerator at 3-5°C.

[0067] (4) Browning inhibitory effect: After fresh-cut potatoes were stored in a cold storage at 3-5°C for 4 days, the browning inhibitory effects of different concentrations o...

Embodiment 2

[0069] (1) Soaking treatment of potatoes in proline solutions with different concentrations: Soak potatoes in proline aqueous solutions with different concentrations (0, 100, 110, 120 mmol / L) at a solution temperature of 20°C for 1 hour. Wherein 0mmol / L proline aqueous solution is clear water control group.

[0070] (2) Potato fresh-cut processing: The processed potatoes are peeled, sterilized, cut into slices (3-5mm thick), drained, and then put into polyethylene bags, and the bag mouth is folded. Store in a refrigerator at 3-5°C.

[0071] (3) Treatment of the control group: the same batch of potatoes of the same variety were not subjected to any soaking treatment. Peeled, sterilized, cut into pieces (3-5mm thick), drained, and then put into a polyethylene bag with the mouth folded. Store in a refrigerator at 3-5°C.

[0072] (4) Browning inhibitory effect: After fresh-cut potatoes were stored in a cold storage at 3-5°C for 4 days, the browning inhibitory effects of differe...

Embodiment 3

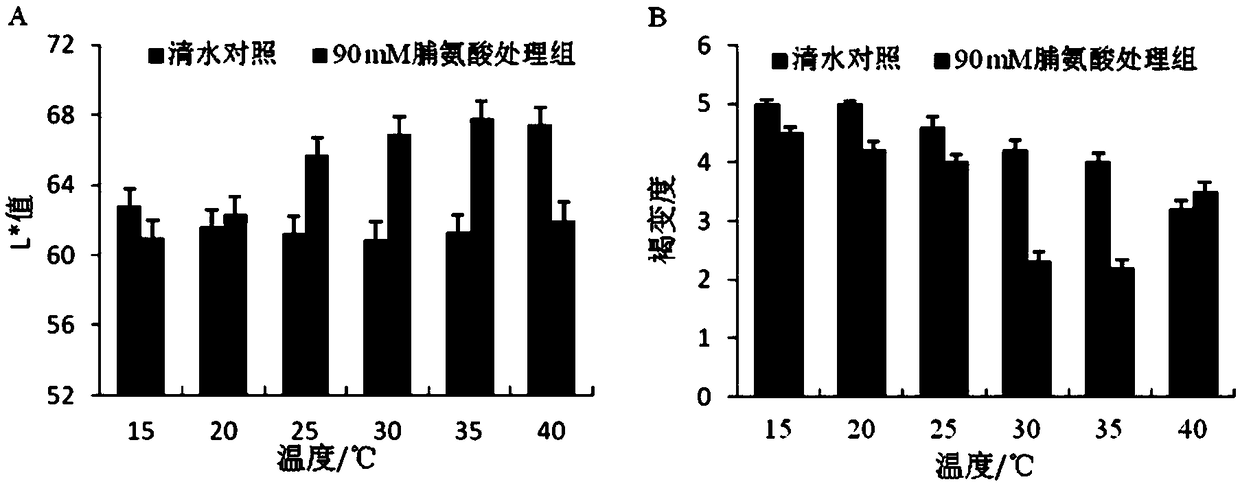

[0074] (1) Soaking treatment of potato proline solution at different temperatures: Soak potatoes in 90mmol / L proline aqueous solution, the solution temperature is 15°C, 20°C, 25°C, 30°C, 35°C, 40°C , Soak for 1h.

[0075] (2) Potato fresh-cut processing: The processed potatoes are peeled, sterilized, cut into slices (3-5mm thick), drained, and then put into polyethylene bags, and the bag mouth is folded. Store in a refrigerator at 3-5°C.

[0076] (3) Clean water control group: soak potatoes of the same variety and batch in clean water at 15°C, 20°C, 25°C, 30°C, 35°C, and 40°C for 1 hour. Peeled, sterilized, cut into pieces (3-5mm thick), drained, and then put into a polyethylene bag with the mouth folded. Store in a refrigerator at 3-5°C.

[0077] (4) Browning inhibitory effect: After fresh-cut potatoes were stored in a cold storage at 3-5°C for 4 days, 90mmol / L proline at 15°C, 20°C, 25°C, 30°C, 35°C, and 40°C respectively The effect of soaking treatment on the browning d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com