Tungsten carbide wear-resistant coating spraying process for oil cylinder

A technology of wear-resistant coating and tungsten carbide, which is applied in coatings and devices for coating liquid on the surface, etc., can solve the problems of poor hardness of the oil cylinder body, poor energy saving and environmental protection effects, and low work efficiency, so as to achieve mature technology and improve The effect of the environmental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

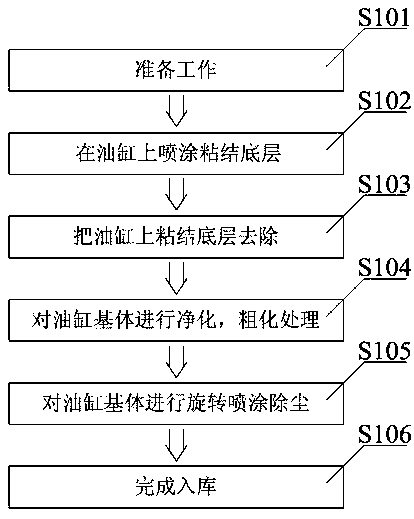

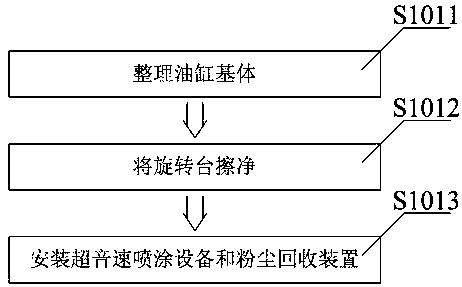

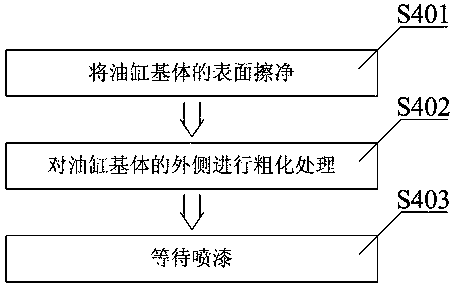

[0073] Embodiment 1: Select and process the oil cylinder substrates to be processed and place them on one side of the rotary table in turn. The diameter of the rotary table is set to 180 cm to 220 cm, and the upper middle position bolt is equipped with a four-jaw single-action chuck. There are also screws installed with handles around the position, manually wipe the table surface of the rotary table with a sponge, install the supersonic spraying equipment and the dust recovery device on the outer side of the rotary table with bolts, and use the nozzle to spray the bonded bottom layer on the cylinder base, Carry out turning on the base body of the oil cylinder, and ensure that the thickness of the base body of the oil cylinder is uniform. A layer of roughening agent with a thickness of 0.1mm to 0.3mm. After the application is completed, wait for the oil cylinder base to be clamped at the upper middle of the rotary table, so that the rotary table can be manually rotated and insta...

Embodiment 2

[0074] Embodiment 2: Select and process the oil cylinder substrates to be processed and place them on one side of the rotary table in turn. The diameter of the rotary table is set to 180 cm to 220 cm, and the upper middle position bolt is equipped with a four-jaw single-action chuck. There are also screws installed with handles around the position, manually wipe the table surface of the rotary table with a sponge, install the supersonic spraying equipment and the dust recovery device on the outer side of the rotary table with bolts, and use the nozzle to spray the bonded bottom layer on the cylinder base, Carry out turning on the base body of the oil cylinder, and ensure that the thickness of the base body of the oil cylinder is uniform. A layer of roughening agent with a thickness of 0.2mm to 0.3mm. After the application is completed, wait for the oil cylinder base to be clamped at the upper middle of the rotary table, so that the rotary table can be manually rotated and insta...

Embodiment 3

[0075] Embodiment 3: Select and process the oil cylinder substrates to be processed and place them on one side of the turntable in sequence. The diameter of the turntable is set at 180 cm to 220 cm, and the upper middle position bolt is equipped with a four-jaw single-action chuck. There are also screws installed with handles around the position, manually wipe the table surface of the rotary table with a sponge, install the supersonic spraying equipment and the dust recovery device on the outer side of the rotary table with bolts, and use the nozzle to spray the bonded bottom layer on the cylinder base, Carry out turning on the base body of the oil cylinder, and ensure that the thickness of the base body of the oil cylinder is uniform. A layer of roughening agent with a thickness of 0.2mm. After the application is completed, wait for the oil cylinder base to be clamped at the upper middle of the turntable, so that the turntable can be manually rotated. The oil cylinder base ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com