Global time optimal trajectory programing method of industrial robot dynamic speed regulation

An industrial robot, time-optimized technology, applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problem of not realizing the track dynamic speed regulation exceeding the limit and normal operation, so as to achieve high-efficiency movement, improve operating accuracy and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, the Cartesian spatial linear planning of an industrial robot is taken as an example to describe in detail. A global time optimal trajectory planning method for dynamic speed regulation of an industrial robot, comprising the following steps:

[0057] S1: Input the starting point and ending point data of the motion trajectory of the industrial robot, and input the maximum linear velocity Max_Velo in Cartesian space, the maximum acceleration Max_Accel in Cartesian space, the maximum angular velocity Max_jointVelo in joint space, and the maximum angular acceleration Max_jointAccel in joint space.

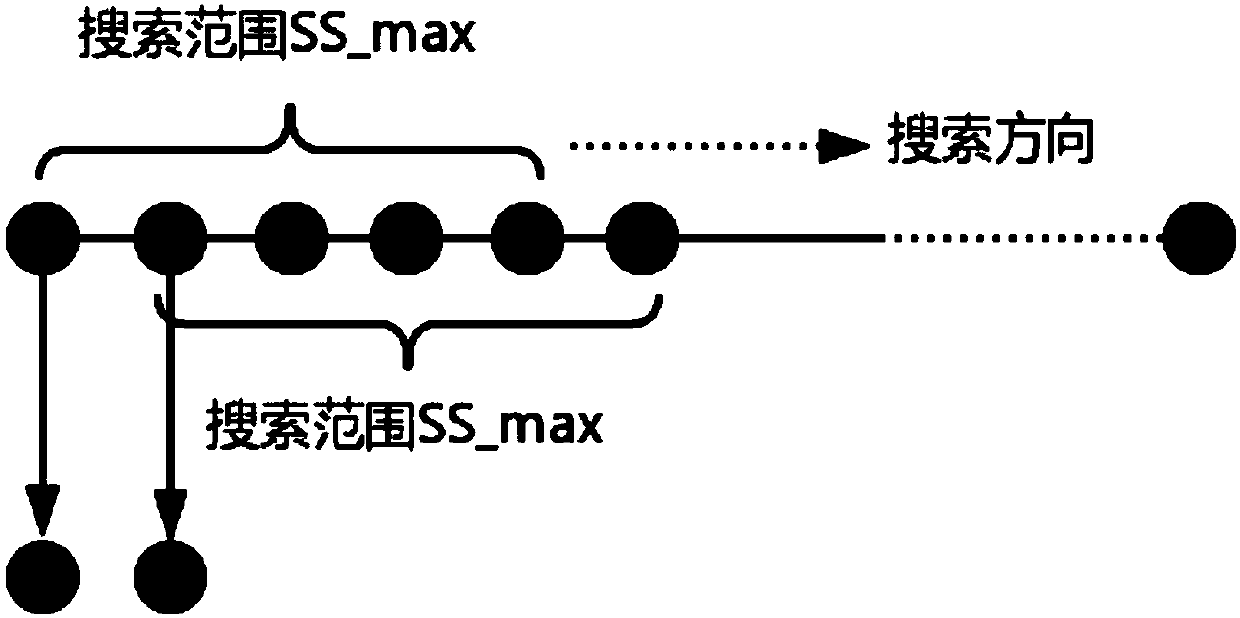

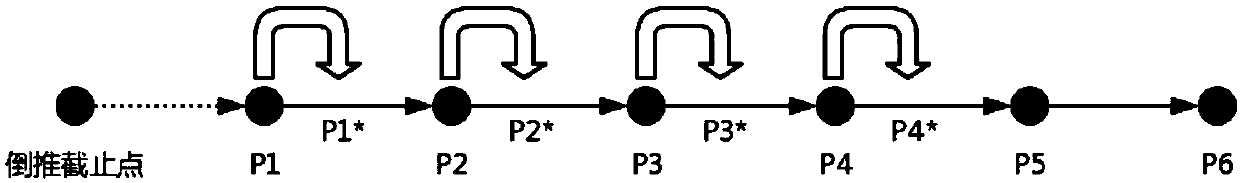

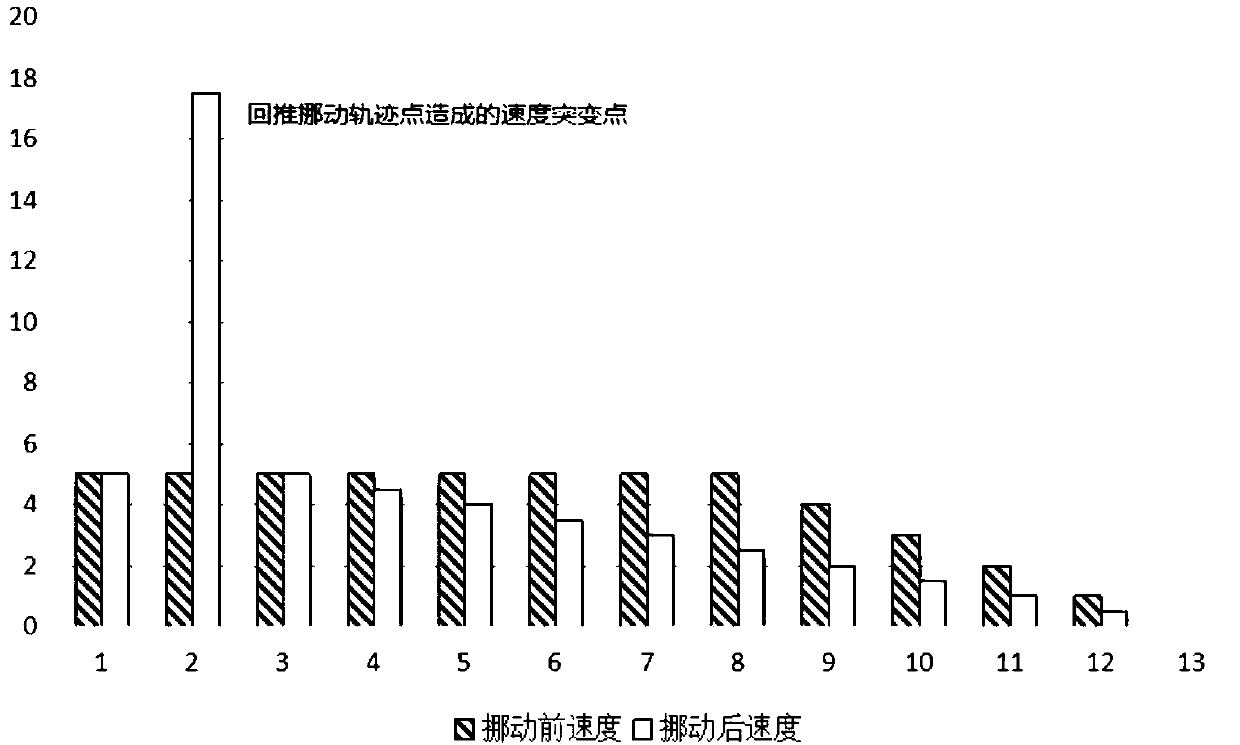

[0058] S2: Pre-calculate the motion trajectory of the robot according to the above constraints: In this embodiment, the trapezoidal acceleration and deceleration method is used to pre-calculate the motion trajectory. The pose vectors (α, β, γ) are jointly represented to obtain a set of Cartesian space trajectory points represented by 6 degrees of freedom pose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com