A kind of polyvinyl alcohol melt with good rheology and its film preparation method

A polyvinyl alcohol-based film and polyvinyl alcohol-based technology are applied in the field of preparation of polyvinyl alcohol-based melts and films, which can solve the problems of easy breakage, uneven dyeing, and poor tensile properties of the film, and avoid The undulation height is too large, which is beneficial to dissolution and modification, and the effect of improving tensile stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

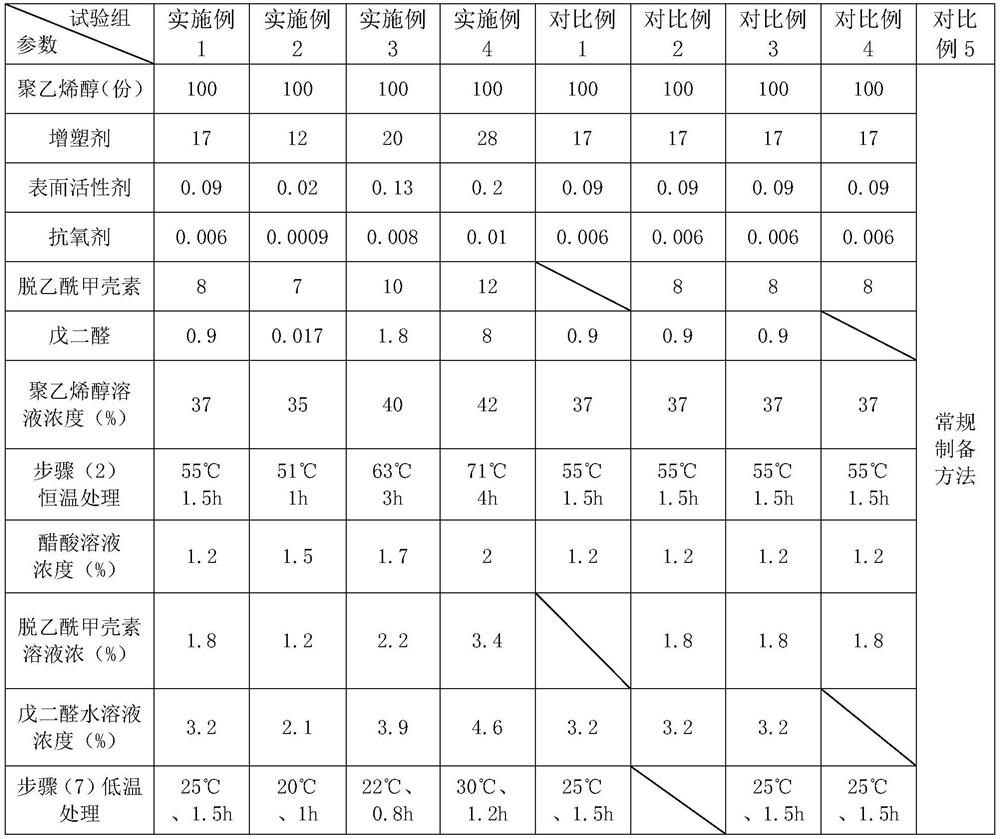

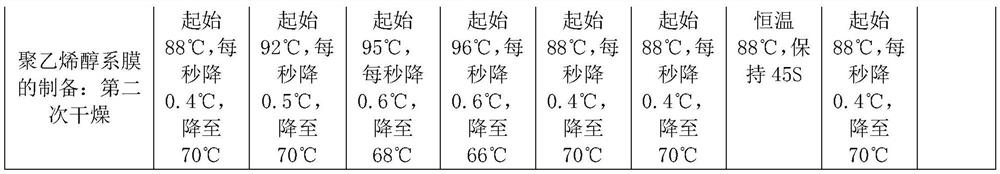

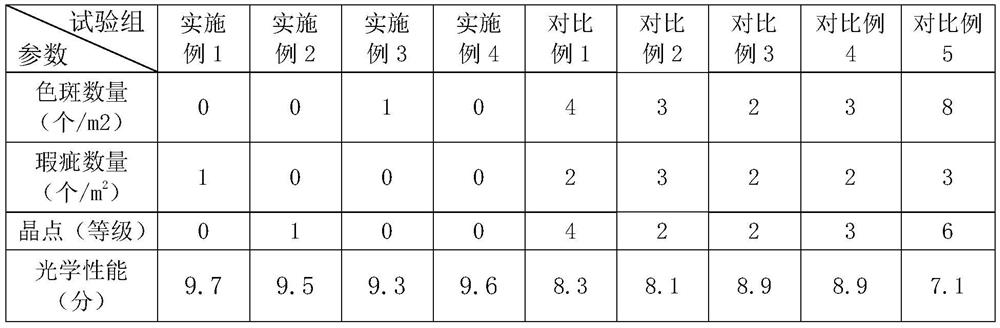

Examples

Embodiment 1

[0042] This embodiment discloses a polyvinyl alcohol melt with good rheological properties, said polyvinyl alcohol melt includes polyvinyl alcohol polymer, water, plasticizer, surfactant and antioxidant, said The temperature of the polyvinyl alcohol melt is 90° C., the load is 2.16 kg, and the melt flow index is 1.0-50 g / min when the water content is 40-70%. After repeated studies by the applicant, it was found that the polyvinyl alcohol film prepared from the polyvinyl alcohol melt has a smooth surface, fewer crystal points, and excellent optical properties; its stretchability and ductility are better than those of polyvinyl alcohol films on the market. Vinyl alcohol-based film, the probability of film breakage during the stretching process is very small; and when dyeing, the dye can be evenly distributed on the polyvinyl alcohol-based film to ensure uniform dyeing of the film.

[0043] The flow index of the polyvinyl alcohol melt is tested on a melt flow rate meter according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com