Environmentally friendly wear-resistant and water-slipping-resistant floor paint for civil air defence and preparation method of environmentally friendly wear-resistant and water-slipping-resistant floor paint

An environmentally friendly, air defense technology, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of not meeting high standards, poor comprehensive performance, poor comprehensive performance, etc., to achieve long service life, anti- The effect of high exfoliation and excellent fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

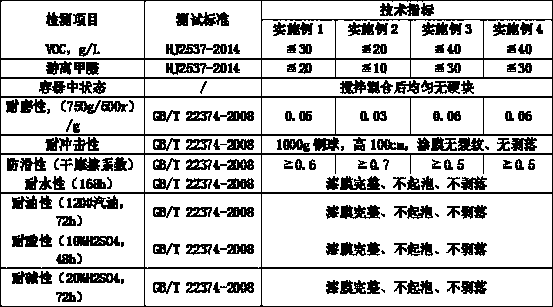

Examples

Embodiment 1

[0039] In this embodiment, each component is calculated in parts by mass.

[0040] An environment-friendly method for preparing wear-resistant, waterproof and slippery floor paint for civil air defense, including the following steps:

[0041] (1) Weigh, and weigh the ingredients according to the composition formula;

[0042] (2) To prepare component A, put 15 parts of epoxy resin, 12 parts of propyl butyrate, 15 parts of propylene oxide butyl ether, 10 parts of selenium oxide, 7 parts of selenium octoate, and 2 parts of iron octoate into the mixing tank , The stirring tank temperature is 75℃, stir for 30min, then add 35 parts of deionized water, continue to stir for 20min, then add 2 parts of phase silica, 1 part of attapulgite, 1 part of titanium dioxide, 3 parts of quartz powder, mica powder After 6 parts, 5 parts of carbon black, continue to stir for 1.5H, the stirring temperature does not change, and the A component is obtained after the stirring is completed;

[0043] (3) Prepar...

Embodiment 2

[0046] In this embodiment, each component is calculated in parts by mass.

[0047] An environment-friendly method for preparing wear-resistant, waterproof and slippery floor paint for civil air defense, including the following steps:

[0048] (1) Weigh, and weigh the ingredients according to the composition formula;

[0049] (2) To prepare component A, put 13 parts of epoxy resin, 13 parts of propyl butyrate, 14 parts of propylene oxide butyl ether, 10.5 parts of selenium oxide, 7.5 parts of selenium octoate, and 2.5 parts of iron octoate into the mixing tank , The stirring tank temperature is 75℃, stir for 30min, then add 37 parts of deionized water, continue to stir for 20min, then add 2.5 parts of phase silica, 0.8 parts of attapulgite, 1.6 parts of titanium dioxide, 3.4 parts of quartz powder, mica powder After 6.5 parts, 4.5 parts of carbon black, continue to stir for 1.5H, the stirring temperature remains unchanged, and the A component is obtained after the stirring is complet...

Embodiment 3

[0053] In this embodiment, each component is calculated in parts by mass.

[0054] An environment-friendly method for preparing wear-resistant, waterproof and slippery floor paint for civil air defense, including the following steps:

[0055] (1) Weigh, and weigh the ingredients according to the composition formula;

[0056] (2) To prepare component A, put 10 parts of epoxy resin, 11 parts of propyl butyrate, 13 parts of propylene oxide butyl ether, 9 parts of selenium oxide, 7 parts of selenium octoate, and 2 parts of iron octoate into the mixing tank , The stirring tank temperature is 75℃, stir for 30min, then add 30 parts of deionized water, continue to stir for 20min, then add 1 part of phase silica, 0.5 part of attapulgite, 1 part of titanium dioxide, 2 parts of quartz powder, mica powder After 5 parts, 4 parts carbon black, continue to stir for 1H, the stirring temperature does not change, and the A component is obtained after the stirring is completed;

[0057] (3) Prepare com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com