Heat pump type tube bundle drier

A tube bundle drying and heat pump technology, which is used in heat pumps, dryers, drying solid materials, etc., to relieve energy shortages, improve drying thermal efficiency, and reduce the probability of running failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

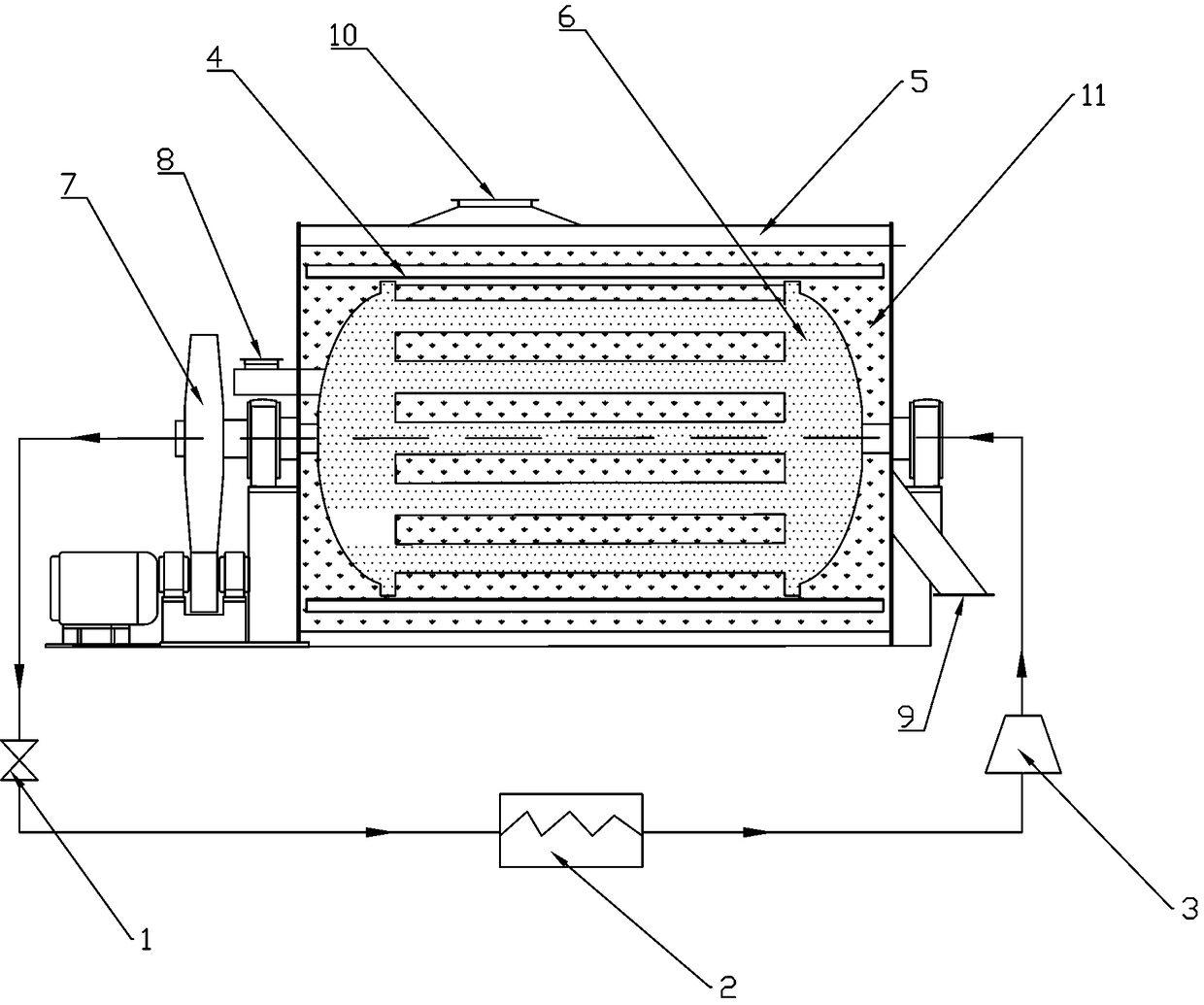

[0025] Such as figure 1 figure 2 As shown, a heat pump tube bundle dryer includes a heat pump unit and a tube bundle dryer unit. The heat pump unit is a closed circuit, and the heat pump unit includes an expansion valve 1, an evaporator 2, a compressor 3 and a dryer unit connected in sequence. The shared tube bundle condenser 6, the heat pump working fluid inlet of the expansion valve 1 is connected to the heat pump working fluid outlet of the tube bundle condenser 6, the heat pump working fluid outlet of the compressor 3 is connected to the heat pump working fluid inlet of the tube bundle condenser 6; the tube bundle dryer The unit includes a tube shell 5, a lifting plate 4, a transmission mechanism 7, a material inlet 8, a material outlet 9, an exhaust gas outlet 10, and a tube bundle condenser shared with the heat pump unit. The tube bundle condenser 6 and the lifting plate 4 are installed in the tube shell Inside 5, the tube bundle condenser 6, as a common part of the he...

Embodiment 2

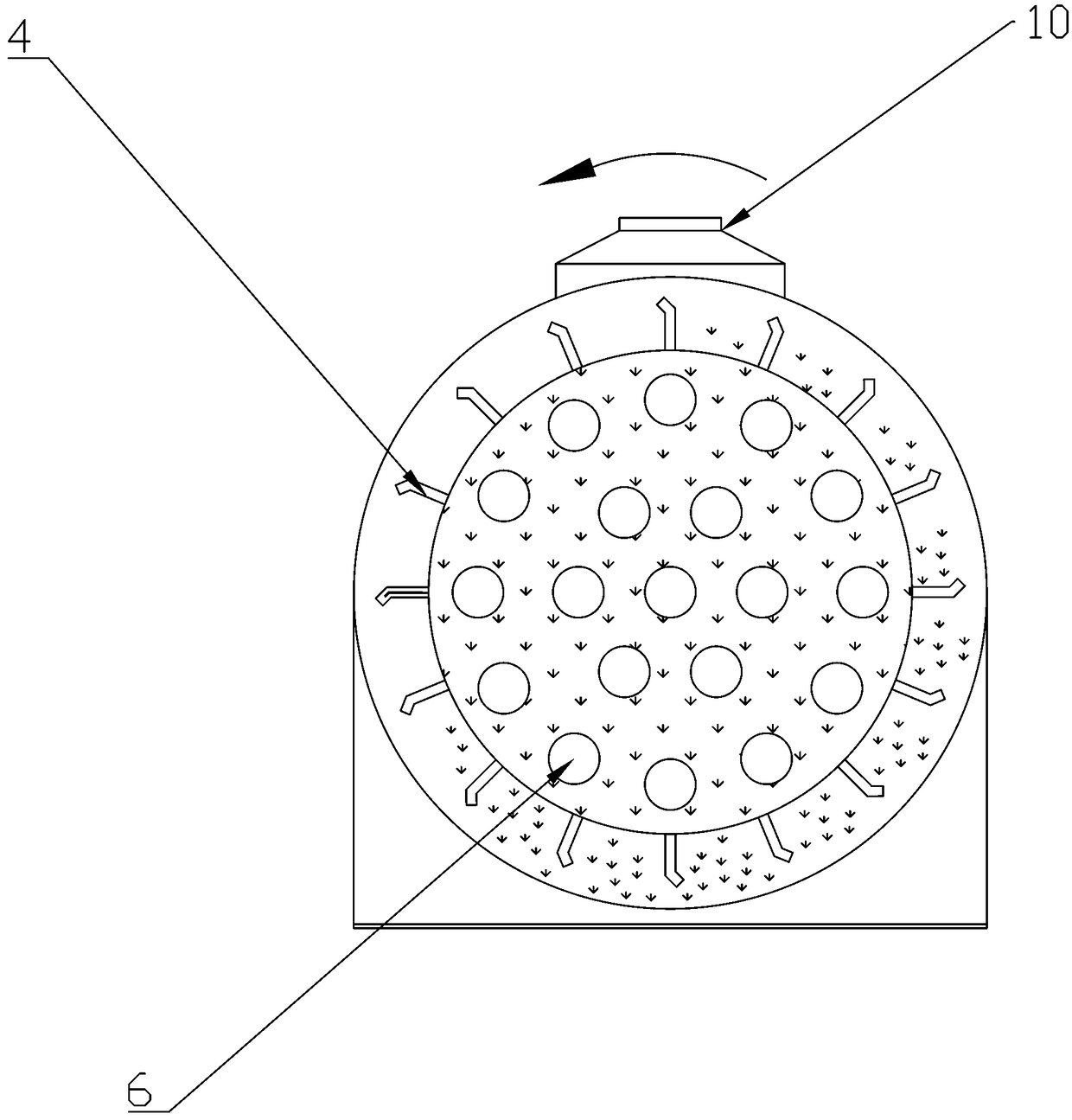

[0029] Embodiment 1 is basically the same as Embodiment 2, except that the tube bundle condenser 6 is arranged in a circular arrangement with a single tube pass, and multiple central exhaust pipes are arranged, and the exhaust gas outlet 10 can be connected to an exhaust gas suction fan. Through multiple central pipes, the heating area of the material can be increased, and the drying efficiency of the material can be improved. Through the waste gas suction fan, the water vapor generated by material drying can be sucked away in time, and the drying efficiency of the dryer can be improved.

Embodiment 3

[0031] The rotating mechanism 7 is connected with the central rotating shaft of the tube bundle condenser 6 and the lifting plate 4, and the rotating mechanism 7 is provided with a speed change transmission. The speed of the rotating mechanism is adjusted by the speed-adjusting transmission, so as to control the speed of the lifting board, to control the flow speed of the material, and to realize the sufficient drying of the material.

[0032] As a person skilled in the art, it needs to be explained that the moving direction of the material can also be in phase with the direction in which the heat pump working fluid enters.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap