Ultrahigh vacuum heating device and heating method thereof

A heating device, ultra-high vacuum technology, applied in the direction of ohmic resistance heating device, electric heating device, measuring device, etc., can solve the problems that it is difficult to have original scientific research results, can not meet the needs, and scientific research is controlled by others, so as to achieve a wide range of sample selection , Heating efficiency and uniformity, the effect of real-time temperature feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

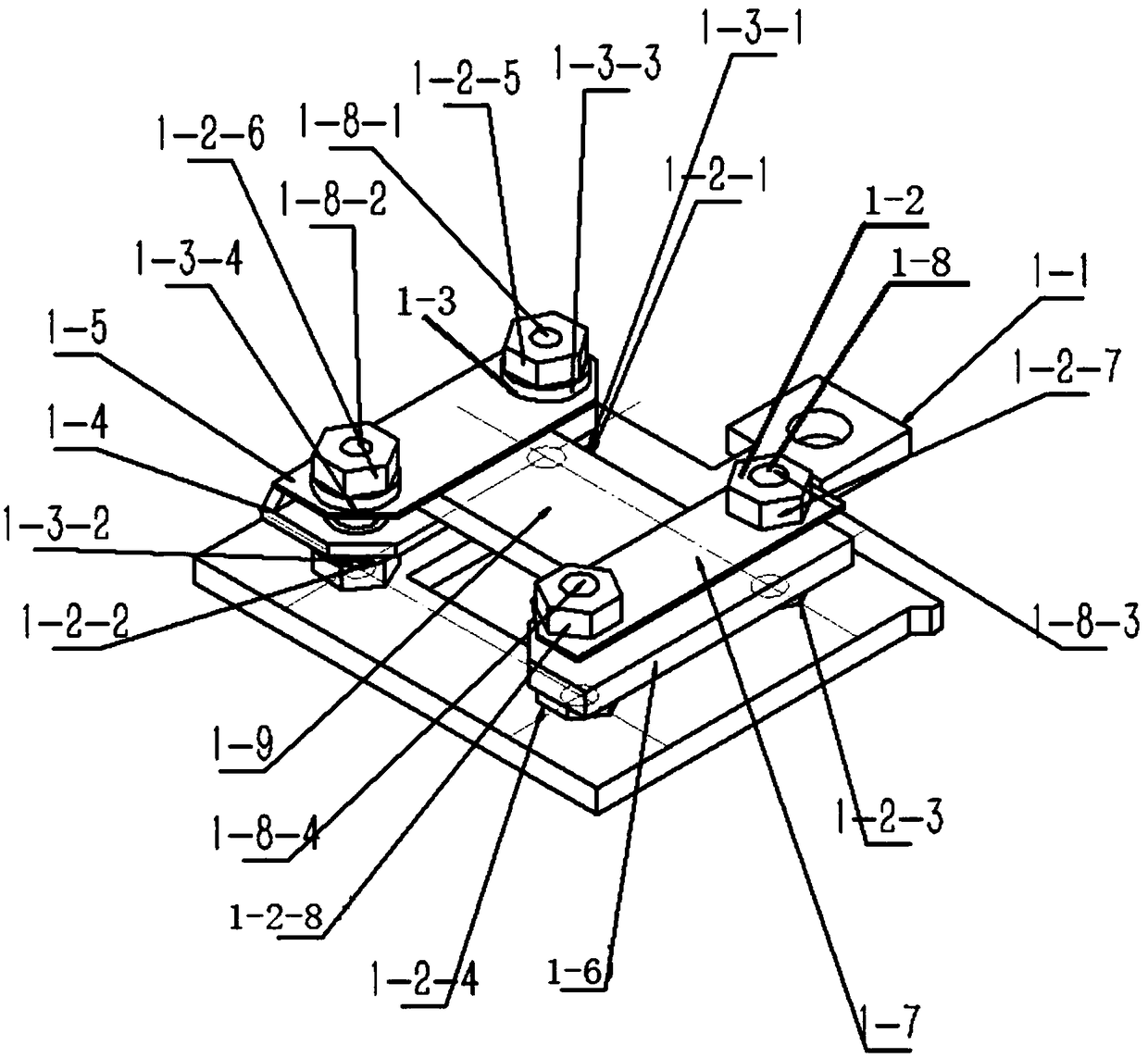

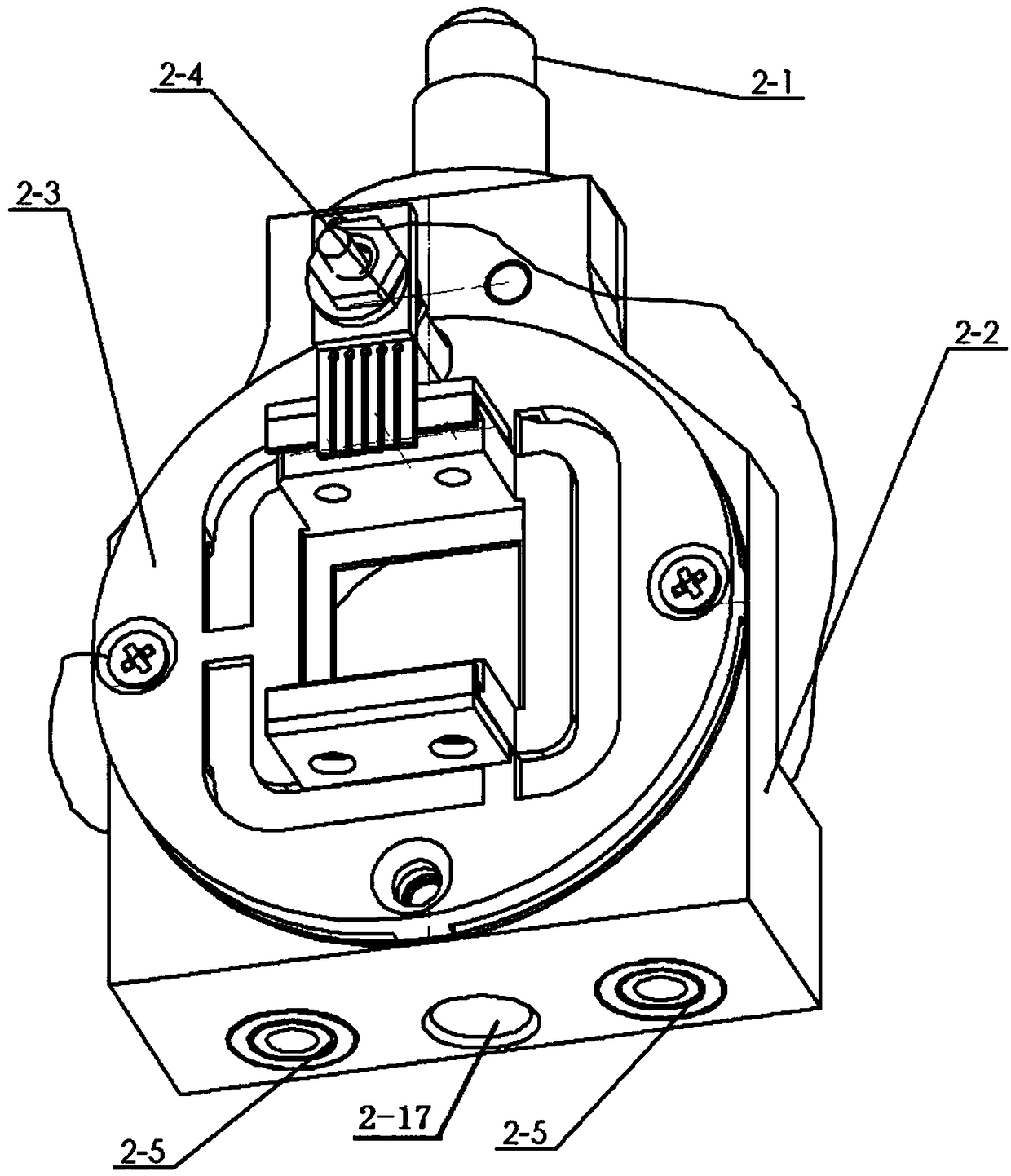

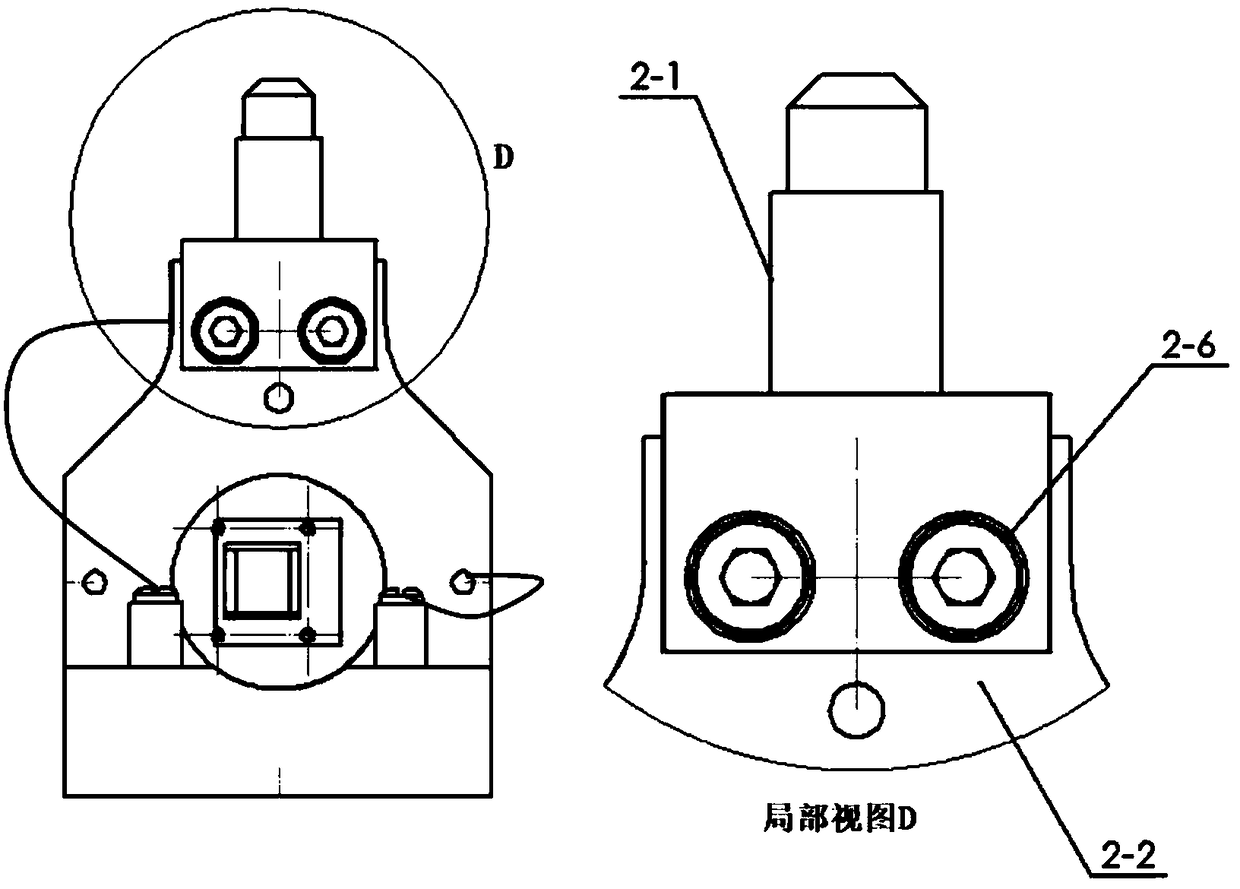

[0040] see Figure 1-11 , an ultra-high vacuum heating device, including a sample holder 1, a heating sample stage 2, and a conductive column positioned in the cavity, wherein:

[0041] to combine figure 1 , sample holder 1 includes hollow sample holder 1-1, nut 1-2, insulating ceramic 1-3, brush electrode piece 1-4, brush electrode pressing piece 1-5, sample holder electrode piece 1-6 1. Connect the sample holder electrode pressing piece 1-7, the sample holder screw rod 1-8, and the sample 1-9 (for example, semiconductor). Build as shown in the schematic diagram, first screw the four sample holder screws 1-8 into the screw holes of the hollow sample holder 1-1, then use the four nuts 1-2 to screw into the sample holder screws 1-8 until fastened to the On the hollow sample holder 1-1; place two insulating ceramics 1-3-1, 1-3-2 on the nut 1-2-1, 1-2 with the small head facing upward on the sample holder screw 1-8 on the right 2-2; put the brush electrode piece 1-4 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com