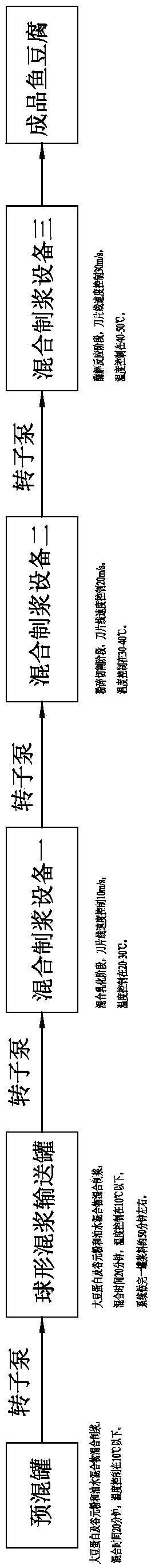

Novel mixing and pulping process for fish tofu and system

A technology of mixing pulp and fish tofu, which is applied to mixers with rotating stirring devices, mixers, dissolving, etc., can solve the problems of backward feeding methods, low production efficiency, poor elasticity of fish tofu, etc., and reduce material overload. The effect of improving the flow area, improving the material conveying efficiency, and evenly mixing the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

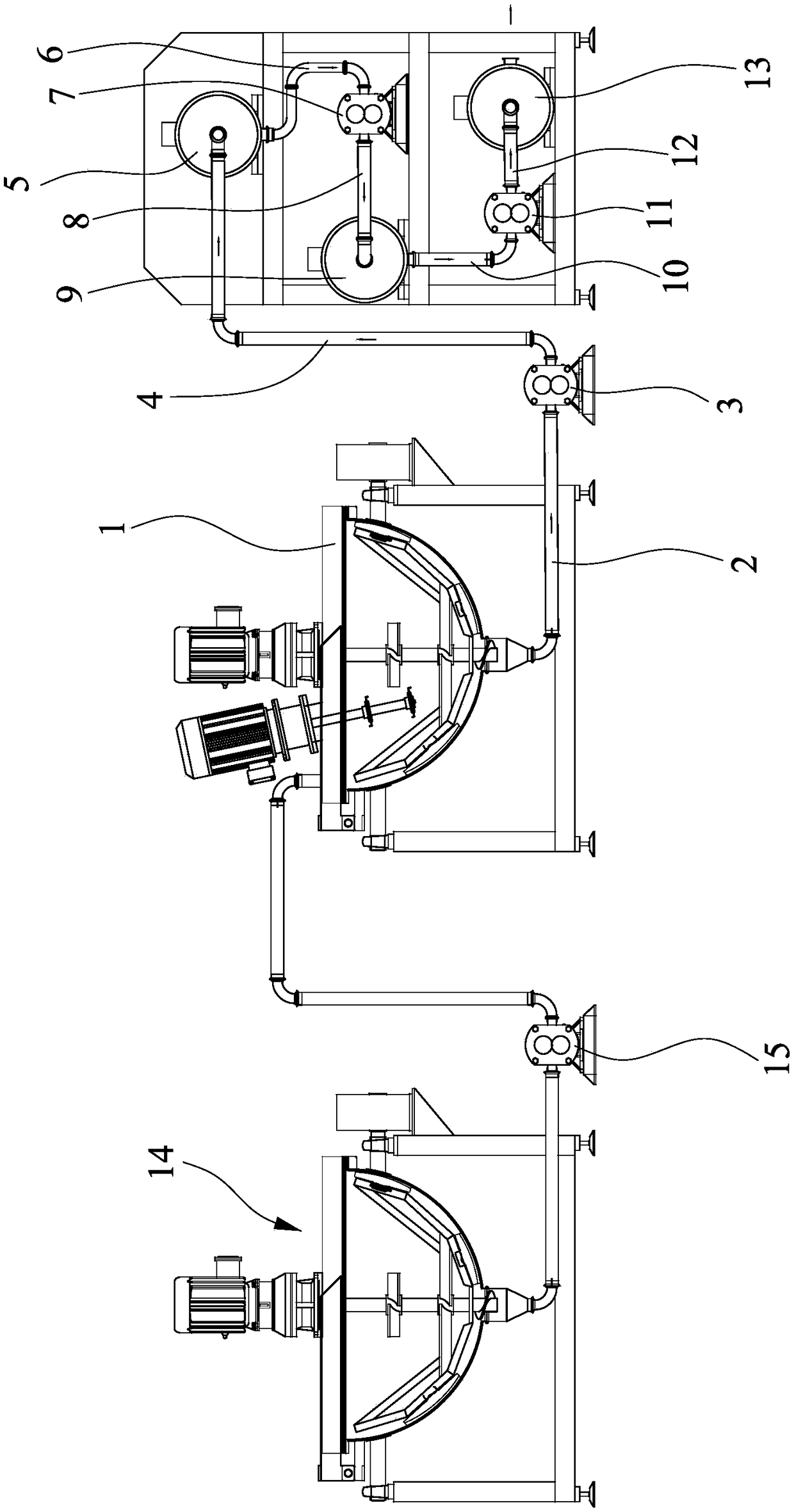

[0035] Such as Figure 1 to Figure 5 As shown, the present invention discloses a novel mixed pulping system for fish tofu, comprising a spherical mixing slurry delivery tank 1, a slurry delivery pipe 2, a cam rotor pump 3, a mixing slurry making equipment 5, a spherical premixing tank 14 and vacuum feeding device 16.

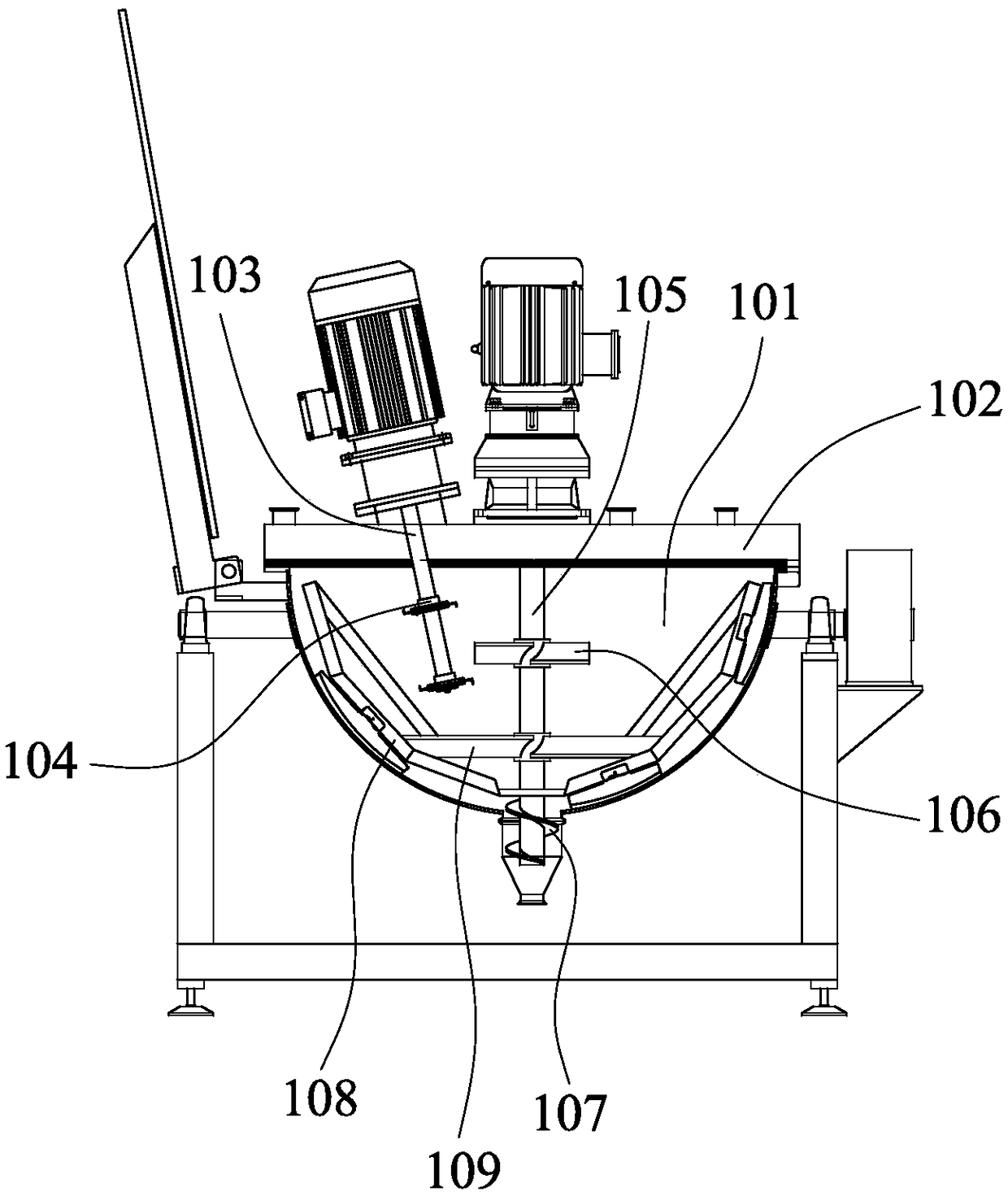

[0036] The spherical slurry mixing tank 1 specifically includes a spherical tank body 101 , a cover plate 102 , a dispersing shaft 103 , a dispersing disc 104 , a stirring shaft 105 , an auxiliary impeller 106 , a screw conveying blade 107 , a PTFE scraper 108 and a stirring paddle 109 . The cover plate 102 is arranged on the top of the spherical tank body 101 , and the cover plate 102 is provided with a feeding port to connect with the vacuum feeding device 16 . Described dispersing shaft 103 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com