High-density and high-stripping deer fiber velvet synthetic leather

A high-peeling, high-density technology, applied in the direction of synthetic resin layered products, coatings, special surfaces, etc., to achieve the effects of fastening, good air permeability, softness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

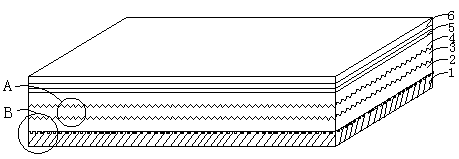

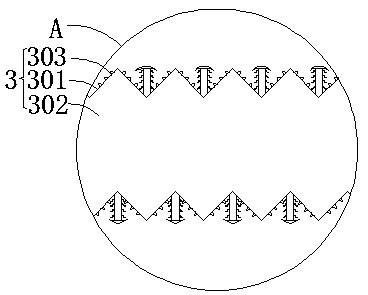

[0032] A high-density and high-stripping deer fiber synthetic leather, comprising a base fabric layer 1, the upper end surface of the base fabric layer 1 is set as a dry-process polyurethane layer 2, and the upper end surface of the dry-process polyurethane layer 2 is provided with an elastic layer 3, the elastic layer 3 Including an elastic skin layer 301 and an inner cavity layer 302, the elastic skin layer 301 has a v-shaped wave structure, the surface of the elastic skin layer 301 is provided with raised particles 303, the dry-process polyurethane layer 2 and the elastic layer 3 have a pore structure, and the elastic The upper end of the layer 3 is coated with a nano-organic fluorine-silicon film layer 4 , and the upper surface of the nano-organic fluorine-silicon film layer 4 is provided with a waterproof membrane 5 , and the upper surface of the waterproof membrane 5 is a handle treatment layer 6 .

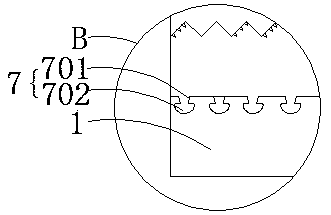

[0033] The upper surface of the base cloth layer 1 is evenly provided wi...

Embodiment 2

[0044] A high-density and high-stripping deer fiber synthetic leather, comprising a base fabric layer 1, the upper end surface of the base fabric layer 1 is set as a dry-process polyurethane layer 2, and the upper end surface of the dry-process polyurethane layer 2 is provided with an elastic layer 3, the elastic layer 3 Including an elastic skin layer 301 and an inner cavity layer 302, the elastic skin layer 301 is a v-shaped wave structure, the surface of the elastic skin layer 301 is provided with raised particles 303, and the upper end of the elastic layer 3 is coated with a nano-organic fluorine silicon film layer 4 , the upper surface of the nano-organic fluorosilicon film layer 4 is a handle treatment layer 6 .

[0045] The upper surface of the base cloth layer 1 is evenly provided with fastening grooves 7, the fastening grooves 7 include liquid ester channels 701, the liquid ester channels 701 are trumpet-shaped structures with a large opening at the upper end and a sma...

Embodiment 3

[0056] A high-density and high-stripping deer fiber synthetic leather, comprising a base fabric layer 1, the upper end surface of the base fabric layer 1 is set as a dry-process polyurethane layer 2, and the upper end surface of the dry-process polyurethane layer 2 is provided with an elastic layer 3, the elastic layer 3 Including an elastic skin layer 301 and an inner cavity layer 302, the elastic skin layer 301 has a v-shaped wave structure, the surface of the elastic skin layer 301 is provided with raised particles 303, the dry-process polyurethane layer 2 and the elastic layer 3 have a pore structure, and the elastic The upper end of the layer 3 is coated with a nano-organic fluorine-silicon film layer 4 , and the upper surface of the nano-organic fluorine-silicon film layer 4 is provided with a waterproof membrane 5 , and the upper surface of the waterproof membrane 5 is a handle treatment layer 6 .

[0057] Production of dry polyurethane layer:

[0058] a: On the release...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com