Bainite steel rail welding joint, and post-weld heat treatment method for controlling 'white block' structure of bainite steel rail welding joint

A technology of post-weld heat treatment and welded joints, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as shortening the service life of rails, achieve the effects of controlling abnormal tissue content, avoiding crack expansion, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] In principle, the present invention has no special limitation on the preparation form of the welded joint, and the preparation form of the bainite rail welded joint well known to those skilled in the art can be used. Those skilled in the art can select according to the actual application situation, product requirements and quality requirements. For selection and adjustment, the welding described in the present invention preferably includes flash welding and / or air pressure welding, more preferably flash welding or air pressure welding. In order to better reduce the mechanical properties of joints reduced by welding of bainitic rails, the present invention can control the quantity and size of "white block" structures in microscopic regions under different conditions. Bainitic rail welded joints are obtained after heat treatment. The heat treatment of the present invention preferably includes three cooling steps. Wherein the heat treatment specifically preferably include...

Embodiment 1

[0100] Air-cool the welded joints of bainite rails with high residual temperature obtained by flash welding. When the welded joints are cooled from 1530°C to 180°C, use medium-frequency induction imitation electric heating coils to heat the entire section of the welded joints of the rails . Stop heating when the tread temperature of the rail reaches 950°C, and then immediately air-cool the obtained rail welded joint to 230°C, at this time, the temperature of the bainite rail welded joint at a lower temperature will rise to a certain extent, wait for the temperature When returning to the highest temperature, add a heat preservation cover, and then slowly cool the welded joint to room temperature (about 23° C.), so as to obtain the welded joint of bainite rail of the present invention through post-weld heat treatment.

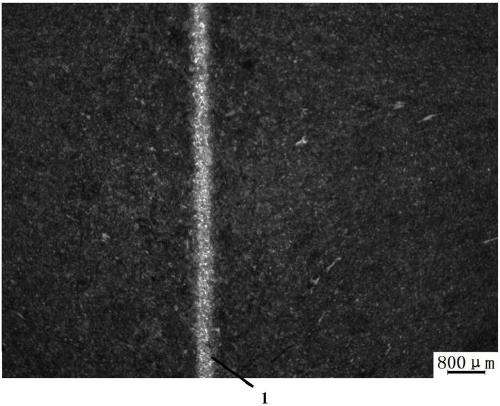

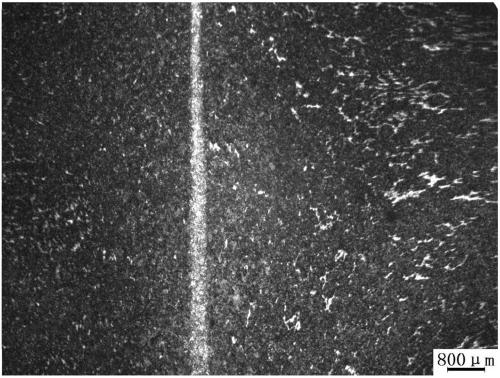

[0101] The bainite rail welded joint obtained in Example 1 was characterized.

[0102] The bainite rail welded joint obtained in this embodiment is machined int...

Embodiment 2

[0107] Air-cool the welded joints of bainite rails with high residual temperature obtained by flash welding. When the welded joints are cooled from 1550°C to 200°C, use an oxy-acetylene flame profiling heater to conduct a full-section inspection of the welded joints of the rails. heating. Stop heating when the tread temperature of the rail reaches 940°C, and then air-cool the welded joint of the rail to 240°C. At this time, the temperature of the welded joint of the bainite rail at a lower temperature will rise to a certain extent, and wait for the temperature to rise to the highest. temperature, add a heat preservation cover, and finally slowly cool the welded joint to room temperature (about 23° C.), thereby obtaining the welded joint of bainite rail of the present invention through post-weld heat treatment.

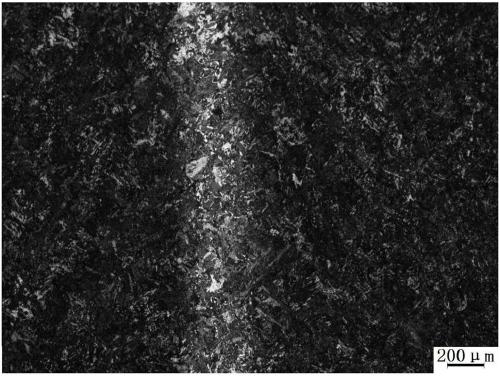

[0108] The bainite rail welded joint obtained in Example 2 was characterized.

[0109] The bainite rail welded joint obtained in this example is machined into a metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com