Thermal barrier coating for gas turbine blades and preparation method of coating

A technology of thermal barrier coatings and turbine blades, applied in coatings, metal material coating processes, fusion spraying, etc., to achieve compact structure, improve overall performance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

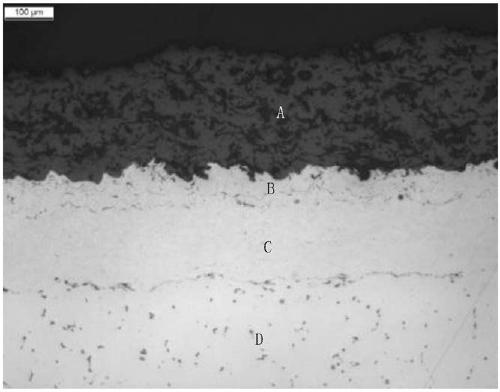

[0022] The thermal barrier coating is prepared with the superalloy substrate material of the first-stage turbine blade of the gas turbine as the carrier. The process flow is: inspection of incoming parts→degreasing with acetone→appearance inspection→dry sand blasting→cleaning→fixture protection→clamping→preheating→overheating Sonic spraying MCrAlY dense layer → supersonic spraying MCrAlY rough layer → heat treatment → plasma spraying YSZ surface layer → inspection.

[0023] The dry blasting treatment before spraying is to clean and activate the alloy surface of the parts, so as to improve the bonding strength between the MCrAlY bottom layer and the alloy matrix.

[0024] The coating preparation steps are:

[0025] 1) Supersonic spraying of MCrAlY (M=Ni) dense layer with a thickness of 0.13mm, and the particle size of MCrAlY powder used for spraying is -88+16μm;

[0026] 2) Supersonic spraying of MCrAlY (M=Ni) rough layer with a thickness of 0.07mm, the particle size of MCrAlY...

Embodiment 2

[0031] The difference with Example 1 is:

[0032] The thickness of supersonic spraying MCrAlY (M=Ni+Co) dense layer is 0.09mm; the thickness of supersonic spraying MCrAlY (M=Ni+Co) rough layer is 0.05mm; after the rough layer is sprayed, the surface roughness Ra is 12μm; plasma spraying The thickness of YSZ surface layer is 0.35mm. The thermal barrier coating has the advantages of good oxidation and corrosion resistance, high interface bonding strength and the like.

Embodiment 3

[0034] The difference with Example 1 is:

[0035] The thickness of supersonic spraying MCrAlY (M=Co) dense layer is 0.15mm; the thickness of supersonic spraying MCrAlY (M=Co) rough layer is 0.06mm; after the rough layer is sprayed, the surface roughness Ra is greater than 10μm; the thickness of plasma spraying YSZ surface layer is 0.45mm. The thermal barrier coating has the advantages of good oxidation and corrosion resistance, high interface bonding strength and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com