Environment-friendly durable monolayer lining structure applicable to soft surrounding rock tunnel

A soft surrounding rock, durable technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of complex construction process, high engineering cost, and many construction consumables, etc., to achieve environmental protection in the production process, short construction period, and construction technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation of the present invention will be further described below in conjunction with examples.

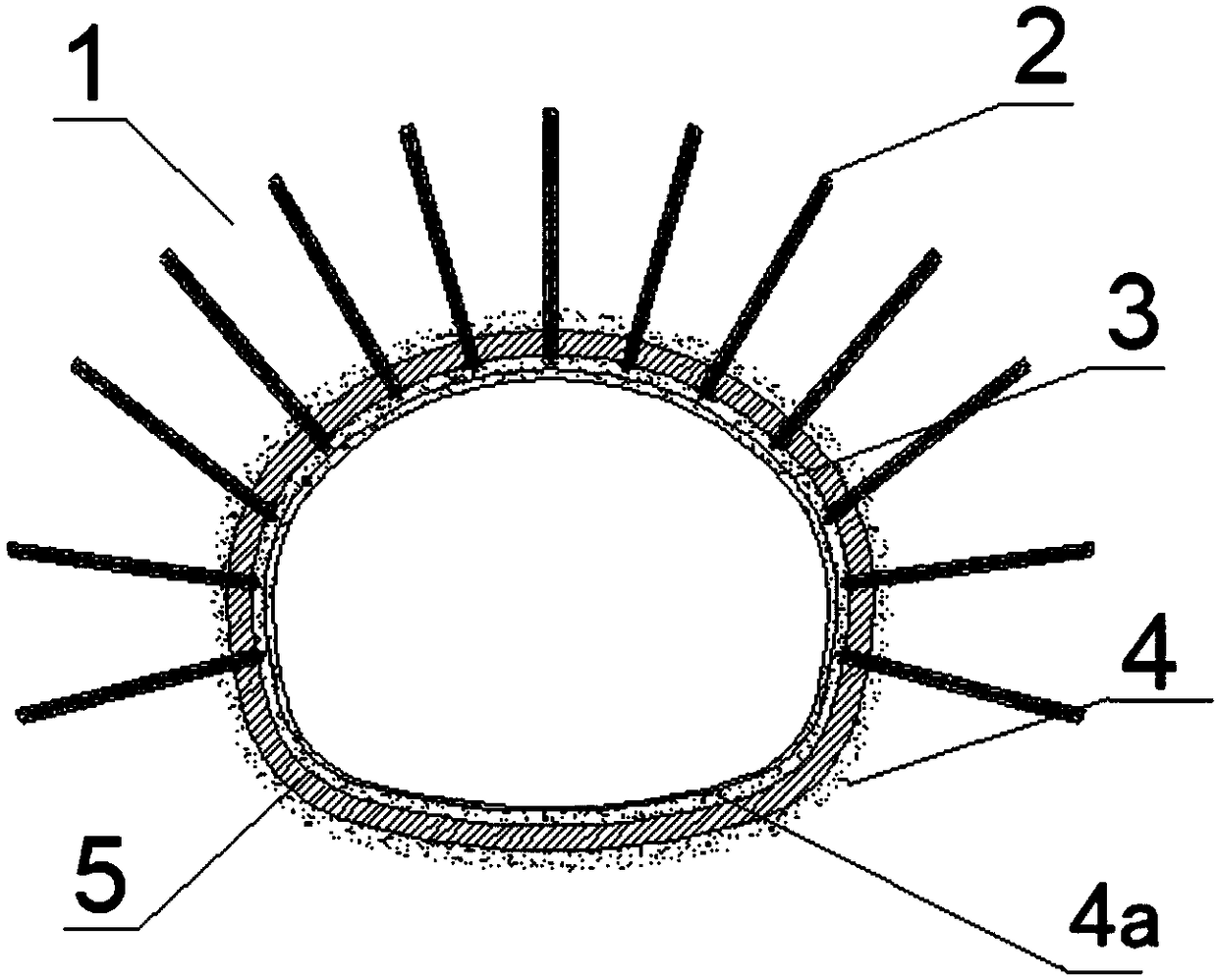

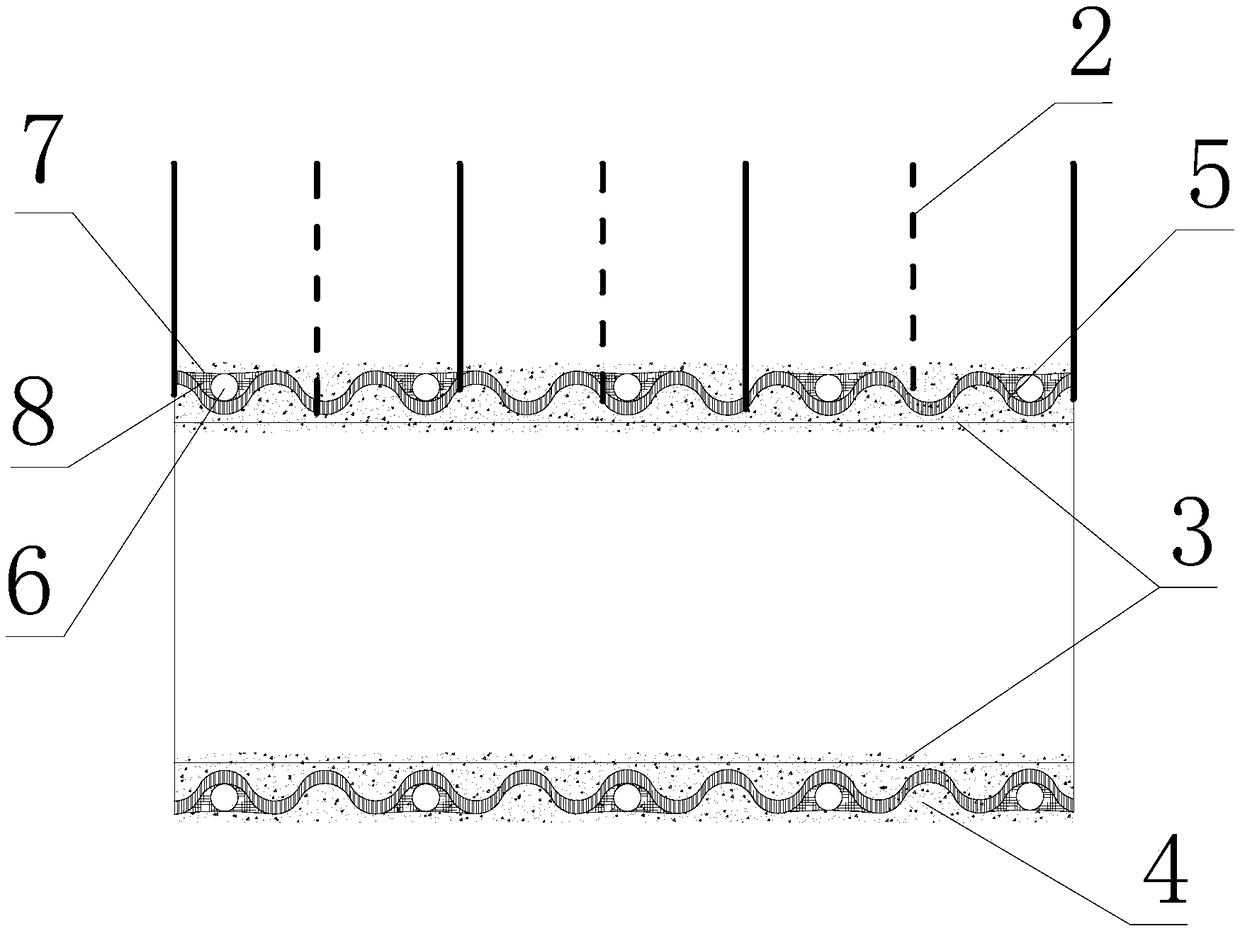

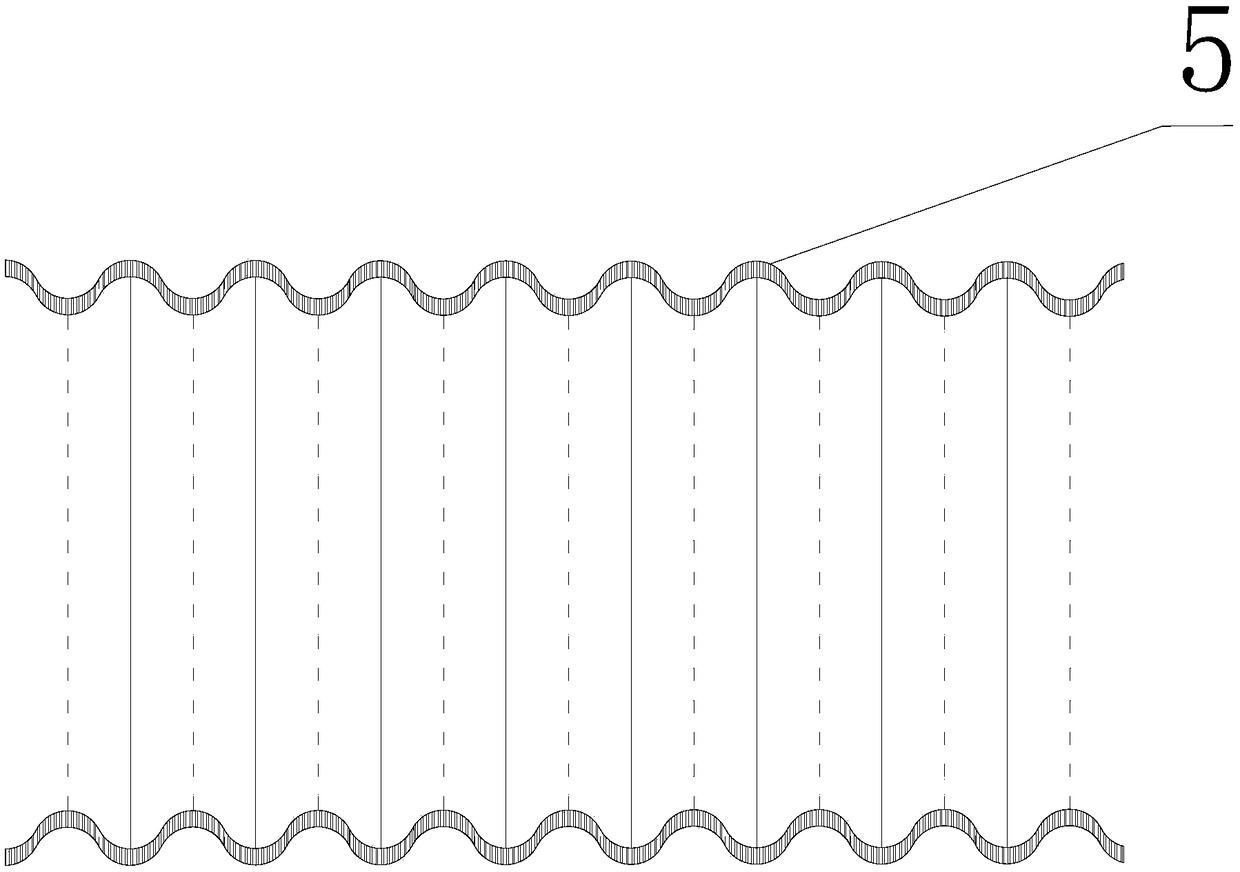

[0036] An environmentally friendly and durable single-layer lining structure suitable for weak surrounding rock tunnels described in the present invention is as follows: figure 1 As shown, it includes weak surrounding rock tunnel 1, (basalt) anchor rod 2, (basalt) steel mesh 3, shotcrete (mixed with basalt fibers) 4a, outer concrete 4, single-layer lining made of corrugated plates 5 , drain pipe 6, non-woven fabric 7, filter material 8, bolt 9, backing plate and bolt 10.

[0037] figure 1 , Figure 5 It shows an environmentally friendly and durable single-layer lining structure suitable for tunnels with weak surrounding rocks. After excavation, concrete 4a mixed with basalt fiber injection is arranged on the inner wall of tunnel 1 with weak surrounding rocks. A single-layer lining 5 composed of corrugated boards, a number of anchor rods 2 driven from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com