Heliostat surface shape on-site detecting system and method

A field detection, heliostat technology, used in solar heating systems, measuring devices, solar ray concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

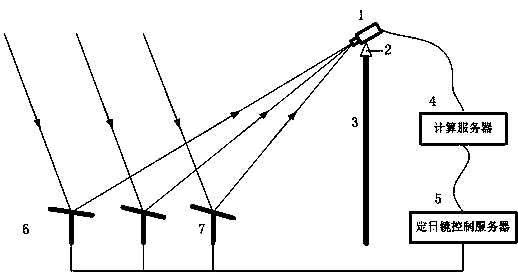

[0073] Such as figure 1 As shown, a heliostat surface shape on-site inspection system includes at least an image acquisition system 1 , a mounting bracket 2 , a computing server 4 and a heliostat control server 5 . The image acquisition system 1 is fixed on the support 3 (traditional heat collection tower, secondary reflection tower or other structure that can fix the image acquisition system 1 at a preset position) through the installation bracket 2, so that the image acquisition system 1 is higher than the heliostat At the center of the mirror, the image acquisition system 1 can be adjusted in pitch angle and azimuth angle through the mounting bracket 2 . The field of view of the image acquisition system 1 covers multiple target heliostats 7 in the mirror field 6, and is used to collect mirror images of the target heliostats 7 in d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com