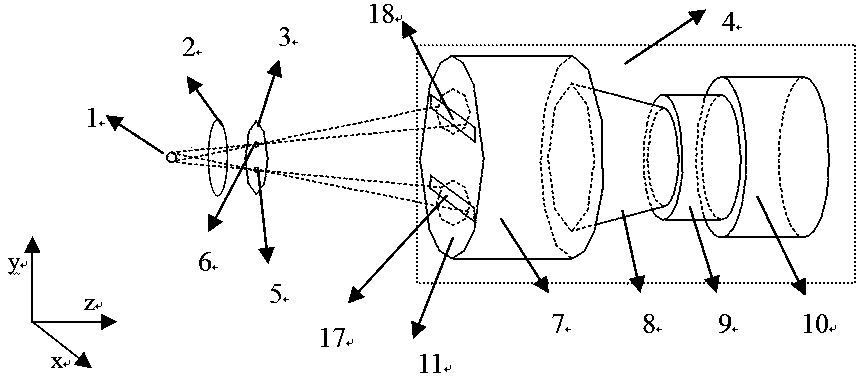

Laser implosion diagnosis system

A diagnostic system and laser technology, applied in the field of laser fusion research, can solve the problems of not being able to obtain target pellets, and achieve the effects of compact structure, broad application prospects, and large dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

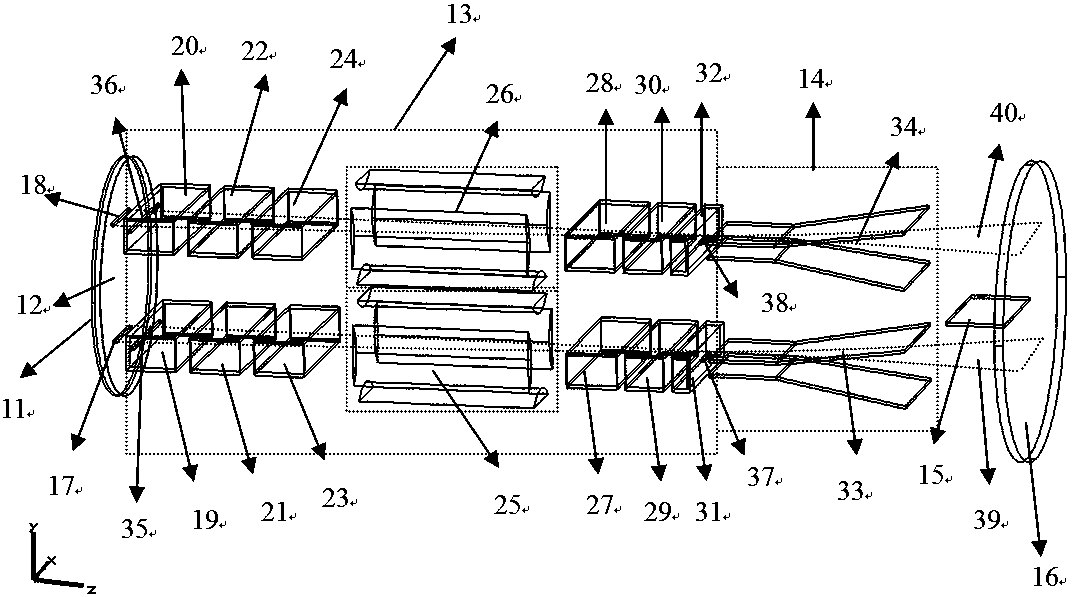

Embodiment 1

[0043]In this embodiment, photocathode 12, grid I19, grid II20, time-direction pre-focus electrode I21, time-direction pre-focus electrode II22, time-direction pre-anode I23, time-direction pre-anode II24, electric quadrupole lens I25, electric four Polar lens focusing II26, main anode in time direction I27, main anode in time direction II28, main focusing electrode in time direction I29, main focusing electrode in time direction II30, anode hole electrode I31, anode hole electrode II32, deflection electrode I33 and deflection electrode II34 There is a corresponding working voltage, so that the electronic focusing lens is formed to focus, image and scan and deflect the electrons emitted by the photocathode 12 . Preferably, the working voltage of the photocathode 12 is -12kV; grid I19, grid II20, time direction pre-anode I23, time direction pre-anode II24, time direction main anode I27, time direction main anode II28, anode hole electrode I31 and The anode hole electrode II32 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com