Water adding-free cosmetic preparation method

A technology for inspection of cosmetics and finished products, applied in the direction of cosmetic preparations, cosmetics, dressing preparations, etc., can solve the problems of large amount of preparation and high cost, and achieve the effect of improving the quality of care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

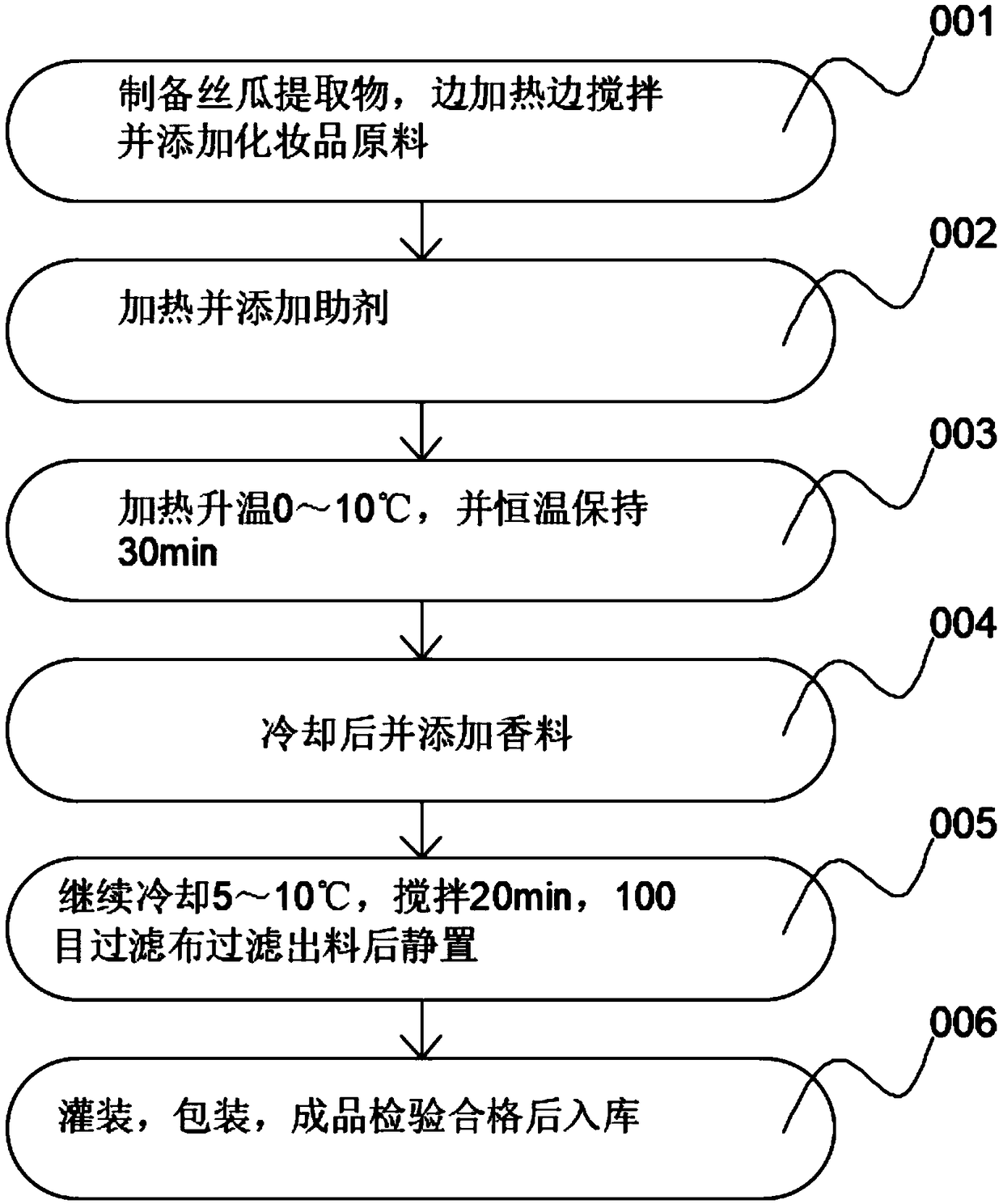

[0060] Such as figure 1 Shown, the present invention provides a kind of cosmetic preparation method without adding water, comprises the steps:

[0061] Step 100, preparing loofah extract, stirring while heating and adding cosmetic raw materials;

[0062] Step 200, heating and adding additives;

[0063] Step 300, heating up to 0-10°C, and keeping the temperature at a constant temperature for 30 minutes;

[0064] Step 400, cooling and adding spices;

[0065] Step 500, continue to cool at 5-10°C, stir for 20 minutes, filter the material with a 100-mesh filter cloth and leave it still;

[0066] Step 600, filling, packaging, and putting the finished product into storage after passing the inspection.

[0067] The temperature after heating in step 200 is 80-85°C; the temperature after cooling in step 400 is 45-55°C.

[0068] In the process of preparing lotion, the standard name of water named AQUA or WATER is not added as a solvent in the preparation process, but the extract of ...

Embodiment 2

[0070] For the preparation of anhydrous facial mask, the specific steps are:

[0071] Step 101. Heat 80-90 parts of loofah extract and keep stirring, add 0.0.1-0.15 parts of carbomer, 0.03-0.08 parts of sodium hyaluronate, 2-4 parts of propylene glycol, and 0.1 parts of hydroxyethyl cellulose in sequence -0.2 copies;

[0072] Step 102, heating to 80-85°C, adding 0.1-0.2 parts of panthenol, 0.1-0.2 parts of allantoin, 0.05 parts of methylparaben, 0.2-4 parts of jojoba wax, and 0.50 parts of PEG-120 esters in sequence;

[0073] Step 103, heating to 85-90°C, and keeping at constant temperature for 30 minutes;

[0074] Step 104, cooling to 45-50°C, adding 0.20 parts of bis(hydroxymethyl) imidazolidinyl urea, peppermint leaf extract, Geranium geranium extract, chamomile extract, Sophora flavescens root extract, and purslane in sequence A total of 0.05 parts of extract and Aloe vera extract, 0.4-0.60 parts of glycerol polymethacrylate, 1-2 parts of dextran; 0.10-0.14 parts of trie...

Embodiment 3

[0078] For preparing anhydrous toner, the specific steps are:

[0079] Step 201, heat 80-90 parts of loofah extract and keep stirring, then add 0.1 part of EDMA and 3-5 parts of glycerin in sequence;

[0080] Step 202, heating to 80-85 degrees, adding 0.15 parts of allantoin, 2-4 parts of propylene glycol, and 0.2-0.4 parts of glycerin polymethacrylate;

[0081] Step 203, heating to 85-90°C, and keeping the temperature constant for 30 minutes;

[0082] Step 204, cooling to 45-50°C, followed by 0.40 parts of DMDM hydantoin, 0-0.30 parts of essence, 0.30 parts of PEG-40 hydrogenated castor oil;

[0083] Step 205, cooling to 40°C, stirring for 20 minutes, filtering out with a 100-mesh filter cloth, and standing still.

[0084] Step 206, filling, packaging, and putting the finished product into storage after passing the inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com