Method for preparing aerated concrete product from solid wastes in calcium carbide industry

A technology for air-entrained concrete and solid waste, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of high cost and low economic benefit, and achieve the goal of realizing resource recycling and ash resource utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

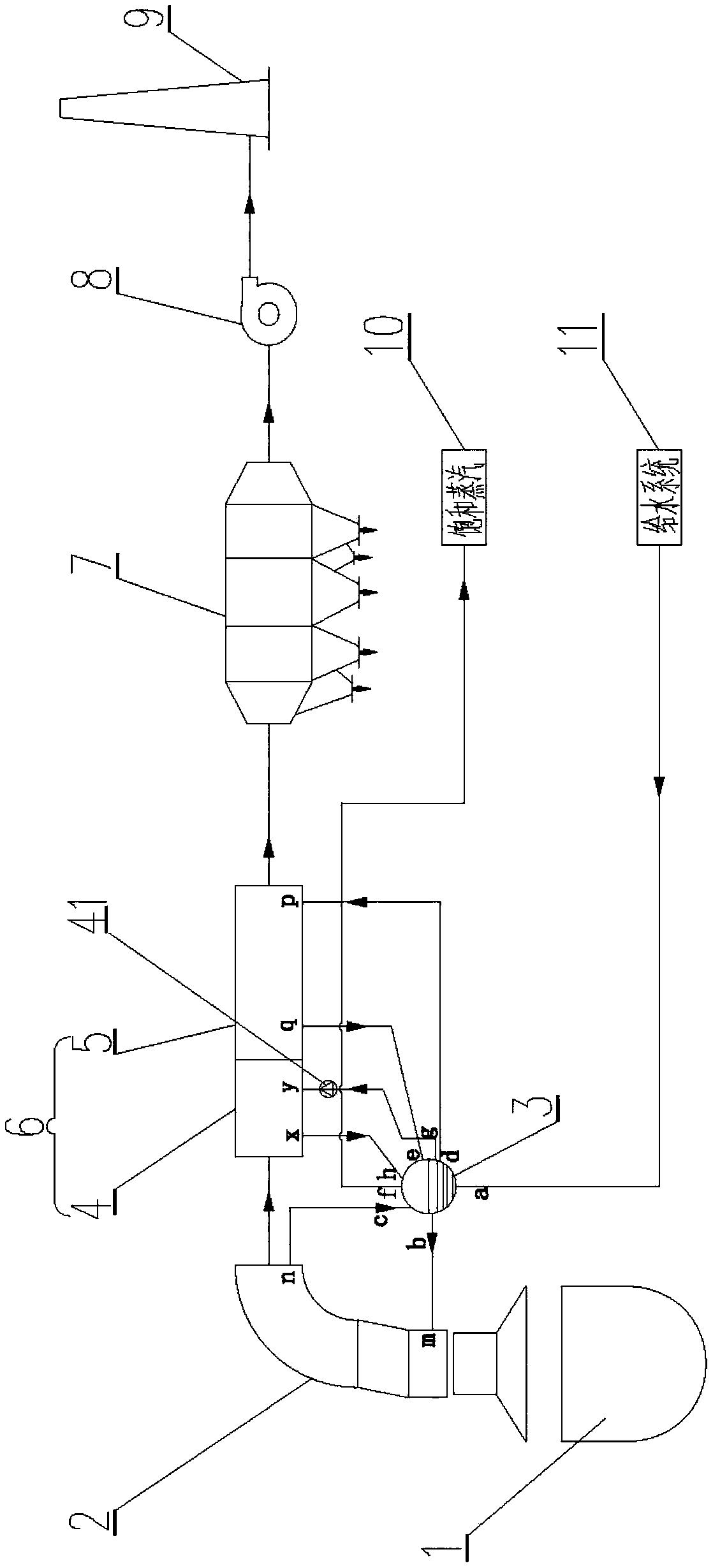

Image

Examples

Embodiment Construction

[0016] The method for preparing air-entrained concrete products from calcium carbide industrial solid waste is further described in conjunction with the following examples.

[0017] A specific implementation of the method for preparing aerated concrete products from calcium carbide industrial solid waste of the present application, the raw material weight percentage components of aerated concrete are: dedusting ash: 19-22%, purified ash: 18-20%, blue Charcoal powder: 30-32%, binder (with figure 1 Adjusting material in): 6-9%, cement: 7-10%, gypsum: 6-10%, aluminum powder: 8-11%, and the sum of the weight percentages of the components is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com