A clean production method of chitosan with high degree of deacetylation

A clean production and high deacetylation technology, applied in the field of marine chemical engineering, can solve problems such as heavy odor, low production efficiency, and difficulty in meeting the requirements of chitosan deacetylation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 500g chitin, add it into 2.5L NaOH solution with a mass fraction of 15%, soak at 40°C for 3h. Then the material was transferred to a 5L vacuum reaction autoclave, the vacuum pressure was -0.078MPa, and the temperature was 70°C for 2 hours. After the reaction was completed, 2.0 L of NaOH solution was recovered by suction filtration. The chitosan was washed with tap water until neutral, and dried at 105° C. for 4 hours to obtain 408 g of chitosan. The lotion is vacuum concentrated to 300mL, and the reclaimed lye and concentrated lye are combined to obtain 2.3L of NaOH lye (concentration 15%). Add 30g of solid NaOH and 200mL of water to obtain 2.5L of NaOH solution with a mass fraction of 15%. Prepare the next batch of chitosan.

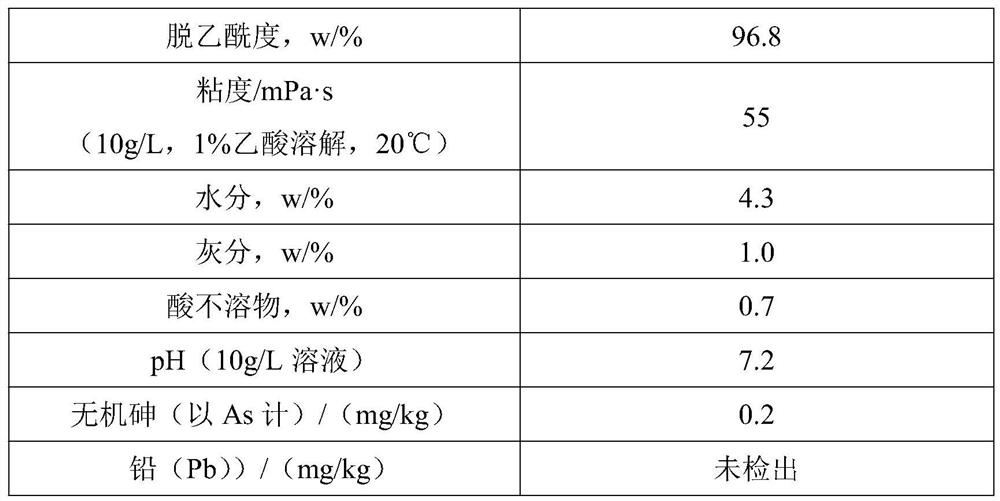

[0019] According to GB29941-2013 detection chitosan sample quality index, the results are as follows:

[0020]

[0021]

Embodiment 2

[0023] Weigh 500g of chitin, add it into 2.5L of KOH solution with a mass fraction of 20%, soak at 50°C for 3h. Then the material was transferred to a 5L vacuum reactor, the vacuum pressure was -0.080MPa, and the temperature was 73°C for 2 hours. After the reaction, 2.1 L of KOH solution was recovered by suction filtration. The chitosan was washed with tap water until neutral, and dried at 105° C. for 4 hours to obtain 400 g of chitosan. The lotion was vacuum-concentrated to 300mL, and the reclaimed lye and concentrated lye were combined to obtain 2.4L of KOH lye (concentration 19%). Add 44g of solid KOH and 100mL of water to obtain 2.5L of KOH solution with a mass fraction of 20%. Prepare the next batch of chitosan. After testing, the deacetylation degree of chitosan is 95.6%, and other indicators meet the requirements of GB29941-2013.

Embodiment 3

[0025] Weigh 500g of chitin, add it into 2.5L of KOH solution with a mass fraction of 25%, soak at 50°C for 1h. Then the material was transferred to a 5L vacuum reactor, the vacuum pressure was -0.085MPa, and the temperature was 80°C for 1.5h. After the reaction, 2.1 L of KOH solution was recovered by suction filtration. The chitosan was washed with tap water until neutral, and dried at 105° C. for 4 hours to obtain 397 g of chitosan. The lotion was vacuum-concentrated to 300mL, and the reclaimed lye and concentrated lye were combined to obtain 2.4L of KOH lye (concentration 23%). Add 73g of solid KOH and 100mL of water to obtain 2.5L of KOH solution with a mass fraction of 45%. Prepare the next batch of chitosan. After testing, the deacetylation degree of chitosan is 97.6%, and other indicators meet the requirements of GB29941-2013.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com