Konjak and kapok fiber moisturizing wet tissue and preparation method thereof

A technology of kapok fiber and konjac, which is applied in fiber treatment, ultrasonic/sonic fiber treatment, physical treatment, etc. It can solve the problems of poor mechanical strength, weak water-locking performance, and easy evaporation of water, so as to achieve enhanced binding force and excellent Water absorption performance, effect of increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

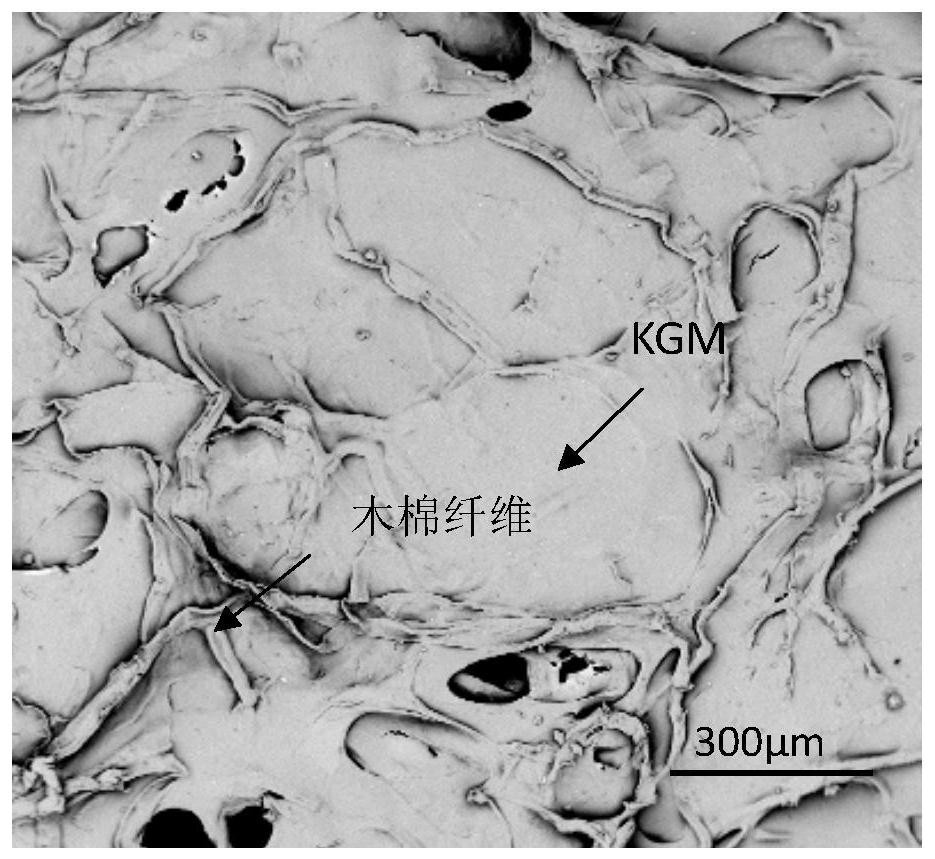

[0042] The invention provides a preparation method of konjac kapok fiber moisturizing wet tissue, which combines konjac glucomannan macromolecule with light industrial papermaking field, and kapok fiber and glucomannan are cross-linked to obtain a dense network similar to paper Cellulose wipes with high stability, good air permeability and high moisture retention. Including the following steps:

[0043] Pretreatment of kapok fiber: take 3 to 3.5 parts of kapok fiber in terms of parts by mass, put it into a low-temperature plasma processor, set the normal pressure treatment atmosphere to oxygen or nitrogen, and the treatment time is 30 to 60s;

[0044] Alkali treatment of kapok fiber: dissolve the pretreated kapok fiber in 96-100 parts of pure water, put it in a mixer at 1000-1500r / min and stir for 10-15 minutes until it is uniform, add 0.48-0.5 parts of anhydrous sodium carbonate Dissolve; add 0.96~1 part of konjac glucomannan after dissolving anhydrous sodium carbonate and p...

Embodiment 1

[0052] This embodiment includes the following steps:

[0053] Kapok fiber pretreatment: put 3.2 parts of kapok fiber into a low-temperature plasma treatment instrument by mass parts to carry out low-temperature plasma pretreatment; the atmosphere used in the low-temperature plasma pretreatment is nitrogen, and the time is 45s; The surface etching degree of kapok fiber after low-temperature plasma pretreatment is 70%, and the etching depth is

[0054] Preparation of mixed solution: disperse the kapok fibers pretreated by low-temperature plasma in 98 parts of water, stir evenly at a speed of 1200r / min for 10min, then add 0.48 parts of anhydrous sodium carbonate until dissolved, and then add 0.98 parts of konjac grape Mannan and 1.2 parts of glycerin were homogeneously swollen for 28 min at a rotating speed of 5000 r / min, and obtained konjac kapok fiber mixed solution after centrifugal degassing;

[0055] Inverted plate film making: spread the prepared konjac kapok fiber mixed...

Embodiment 2

[0077] This embodiment includes the following steps:

[0078]Kapok fiber pretreatment: put 3.2 parts of kapok fiber into a low-temperature plasma treatment instrument by mass parts to carry out low-temperature plasma pretreatment; the atmosphere used in the low-temperature plasma pretreatment is nitrogen, and the time is 45s; The surface etching degree of kapok fiber after low-temperature plasma pretreatment is 70%, and the etching depth is

[0079] Preparation of mixed solution: disperse the kapok fibers pretreated by low-temperature plasma in 98 parts of water, stir evenly at a speed of 1200r / min for 10min, then add 0.48 parts of anhydrous sodium carbonate until dissolved, and then add 0.98 parts of konjac grape Mannan and 1.2 parts of glycerin were homogeneously swollen for 28 min at a rotating speed of 5000 r / min, and obtained konjac kapok fiber mixed solution after centrifugal degassing;

[0080] Inverted plate film making: spread the prepared konjac kapok fiber mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com