Preparation method of low-molecular chitosan

A low-molecular-weight chitosan and chitosan technology, applied in the field of chitosan degradation, can solve the problems of high-concentration alkali dosage, reduced chitosan performance, poor selectivity, etc., to reduce the amount of use and simplify repeated deacetylation the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

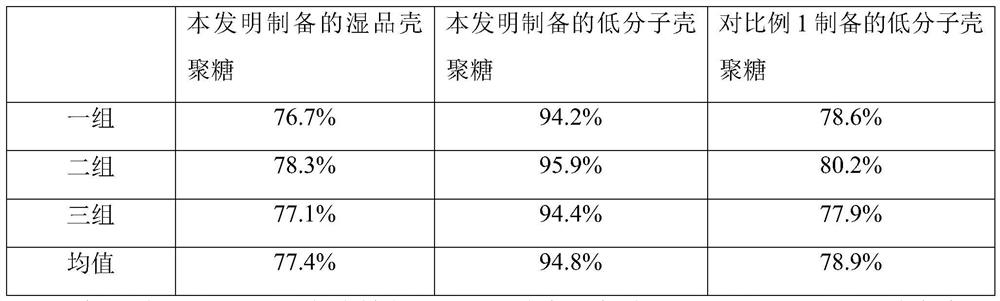

Examples

Embodiment 1

[0039] A preparation method of low-molecular chitosan, carried out as follows:

[0040] Step 1, prepare wet product chitosan

[0041] (1), acid treatment

[0042] Wash, dry, and crush the crab shells to a diameter of 0.5-1 cm, add 5% dilute hydrochloric acid aqueous solution, submerge the crab shells, turn on the ultrasound, raise the temperature to 50°C, keep for 2 hours, and then add deionized water to make the original dilute hydrochloric acid The concentration is reduced to 1%, then add benzoic acid aqueous solution with a mass concentration of 0.5%, form a mixed acid solution with dilute hydrochloric acid, the molar ratio of dilute hydrochloric acid and benzoic acid is 1:0.2, and continue ultrasonication for 2h;

[0043] (2), alkali treatment

[0044] After removing the acidic liquid by filtration, add an aqueous solution of sodium hydroxide with a mass concentration of 12% to the solid insolubles, heat-treat at 90°C for 1 hour, filter and wash with deionized water unti...

Embodiment 2

[0052] A preparation method of low-molecular chitosan, carried out as follows:

[0053] Step 1, prepare wet product chitosan

[0054] (1), acid treatment

[0055] Clean, dry, and crush the crab shells to a diameter of 0.5-1 cm, add a 2% aqueous solution of dilute hydrochloric acid to submerge the crab shells, turn on the ultrasonic wave, raise the temperature to 40°C, and keep it for 3 hours, then add deionized water to make the original dilute hydrochloric acid The concentration is reduced to 0.5%, and then benzoic acid aqueous solution with a mass concentration of 3% is added to form a mixed acid solution with dilute hydrochloric acid. The molar ratio of dilute hydrochloric acid and benzoic acid is 1:0.3, and the ultrasound is continued for 1h;

[0056] (2), alkali treatment

[0057] After removing the acidic liquid by filtration, add an aqueous solution of sodium hydroxide with a mass concentration of 8-12% to the solid insoluble matter, heat-treat at 80°C for 1.5h, filte...

Embodiment 3

[0065] A preparation method of low-molecular chitosan, carried out as follows:

[0066] Step 1, prepare wet product chitosan

[0067] (1), acid treatment

[0068] Wash, dry, and crush the crab shells to a diameter of 0.5-1 cm, add a 3% aqueous solution of dilute hydrochloric acid to submerge the crab shells, turn on the ultrasound, raise the temperature to 45°C, and keep it for 2.5 hours, then add deionized water to make the original dilute hydrochloric acid The concentration of the solution was reduced to 0.8%, and then an aqueous solution of benzoic acid with a mass concentration of 1.5% was added to form a mixed acid solution with dilute hydrochloric acid. The molar ratio of dilute hydrochloric acid to benzoic acid was 1:0.25, and the ultrasound was continued for 1.5h;

[0069] (2), alkali treatment

[0070] After removing the acidic liquid by filtration, add sodium hydroxide aqueous solution with a mass concentration of 10% to the solid insoluble matter, heat treatment a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com