Preparation technology of fly maggot chitin and chitosan

A technology of fly maggot chitin and chitosan, applied in the biological field, can solve the problems of poor product quality, environmental pollution and high cost, and achieve the effects of low water content, shortened reaction time and high degree of deacetylation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

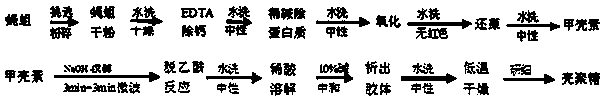

[0102] Present embodiment is the preparation technology of fly maggot chitin, prepares according to the following steps:

[0103] (1) Raw material pretreatment

[0104] Crush the dried fly maggots, wash them with water, wash off a large amount of protein components, and filter and collect the remaining maggot skins for later use;

[0105] (2) EDTA decalcification

[0106] Weigh the clean and dry fly maggot skins obtained in step (1), soak them in (0.3mol / L) saturated EDTA solution for 24 hours to remove calcium, then filter to remove EDTA (recycling), and remove the maggot skins Wash with water until neutral;

[0107] (3) Dilute alkali to remove protein

[0108] Use 10% NaOH aqueous solution on the maggot skin treated in step (2) and boil water bath for 2 hours to hydrolyze the protein. Stir continuously during heating, and replace the lye every half hour. After heating, remove the lye and wash with water until neutral , to obtain crude chitin;

[0109] (4) Refin...

Embodiment 2

[0112] Present embodiment is the preparation technology of fly maggot chitin, prepares according to the following steps:

[0113] (1) Raw material pretreatment

[0114] Crush the dried fly maggots, wash them with water, wash off a large amount of protein components, and filter and collect the remaining maggot skins for later use;

[0115] (2) EDTA decalcification

[0116] Weigh the clean and dry fly maggot skins obtained in step (1), soak them in saturated EDTA solution for 20 hours, remove calcium, filter to remove EDTA (recycling), and wash the maggot skins with water until neutral;

[0117] (3) Dilute alkali to remove protein

[0118] Use 8% NaOH aqueous solution on the maggot skin treated in step (2) and boil water bath for 1.5h to hydrolyze the protein. Stir continuously during the heating period and replace the lye every half hour. properties, to obtain crude chitin;

[0119] (4) Refined finished products

[0120] The crude chitin obtained in step (3) was ...

Embodiment 3

[0122] Present embodiment is the preparation technology of fly maggot chitin, prepares according to the following steps:

[0123] (1) Raw material pretreatment

[0124] Crush the dried fly maggots, wash them with water, wash off a large amount of protein components, and filter and collect the remaining maggot skins for later use;

[0125] (2) EDTA decalcification

[0126] Weigh the clean and dry fly maggot skins obtained in step (1), soak them in saturated EDTA solution for 30 hours, remove calcium, filter to remove EDTA (recyclable reuse), and wash the maggot skins with water until neutral;

[0127] (3) Dilute alkali to remove protein

[0128] Use 12% NaOH aqueous solution on the maggot skins treated in step (2) for 3 hours in a boiling water bath to hydrolyze the protein, stir continuously during heating, and replace the lye every half an hour. After heating, remove the lye and wash with water until neutral , to obtain crude chitin;

[0129] (4) Refined finished p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com