High-speed gas hydrate synthesizer under electrostatic field action

A synthesis device, hydrate technology, applied in chemical/physical/physicochemical process of applying energy, method of chemically changing substances by using atmospheric pressure, chemical/physical process, etc., can solve slow growth rate, gas hydrate Long induction time and other problems, to achieve the effect of low device cost, easy upgrading and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

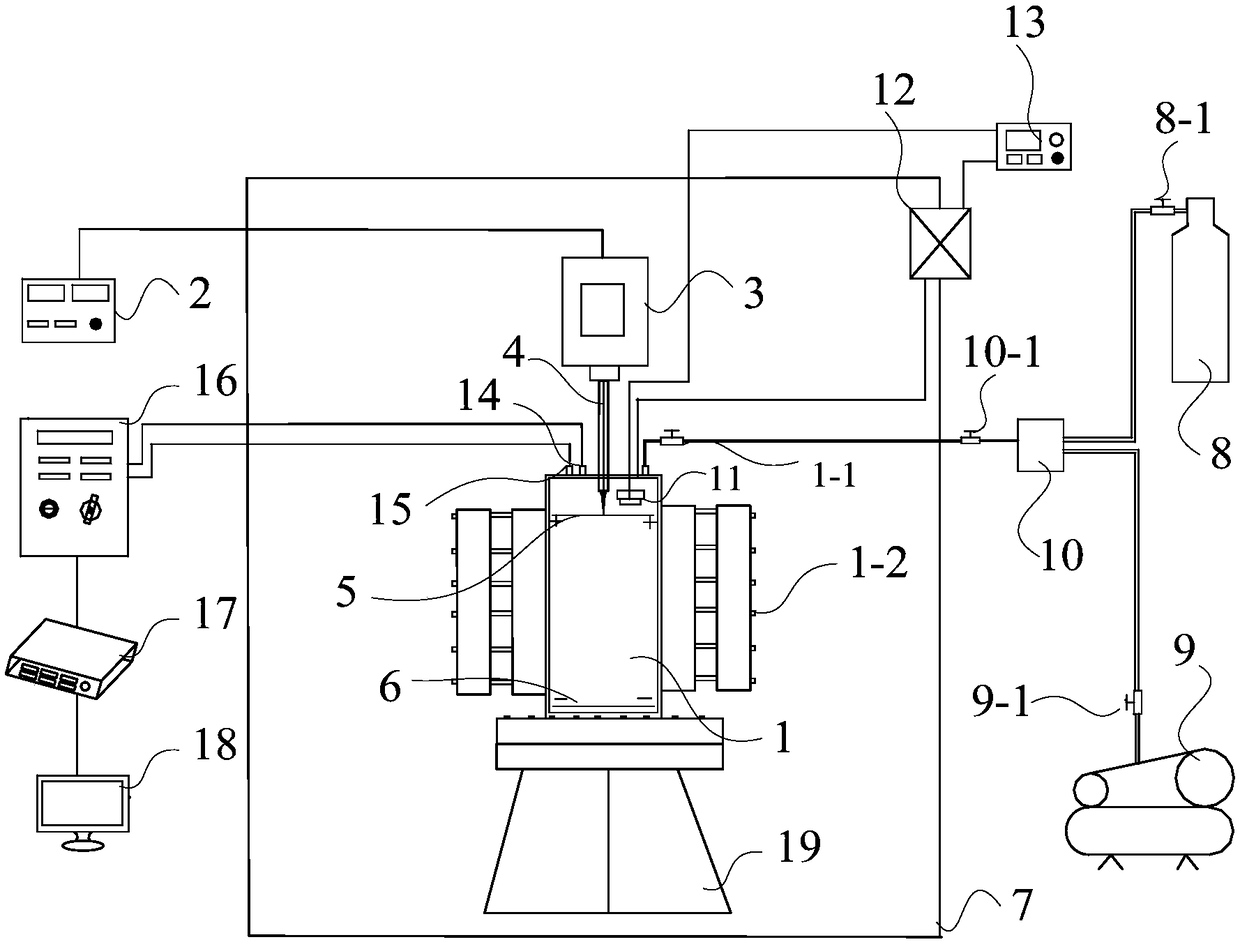

[0027] Specific embodiments: the present invention provides a high-speed gas hydrate synthesis device under the action of an electrostatic field, combining figure 1 As shown, it includes a high-pressure reactor 1, an electrostatic discharge industrial computer 2, an electrostatic discharger 3, a radiation needle 4, a positive electrode plate 5 and a negative electrode plate 6,

[0028] The high-pressure reactor 1 is used to generate gas hydrate under set conditions; the inner bottom of the high-pressure reactor 1 is provided with a negative electrode plate 6, and the port side of the high-pressure reactor 1 is provided with a positive electrode plate 5, a positive electrode plate 5 and a negative electrode plate 6 are respectively electrically connected to the positive pole and the negative pole of the electrostatic discharger 3; the positive electrode plate 5 is connected to the electrostatic discharger 3 through the radiation needle 4, and the tip of the radiation needle 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com