Oil-gas separator assembly of crankcase ventilation system and vehicle

An oil-gas separator and crankcase ventilation technology, which is applied in the field of vehicles, can solve problems such as engine oil loss, increased air pollution, and oil leakage from seals, and achieve the effects of increasing the flow cross-sectional area, increasing the flow rate, and improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

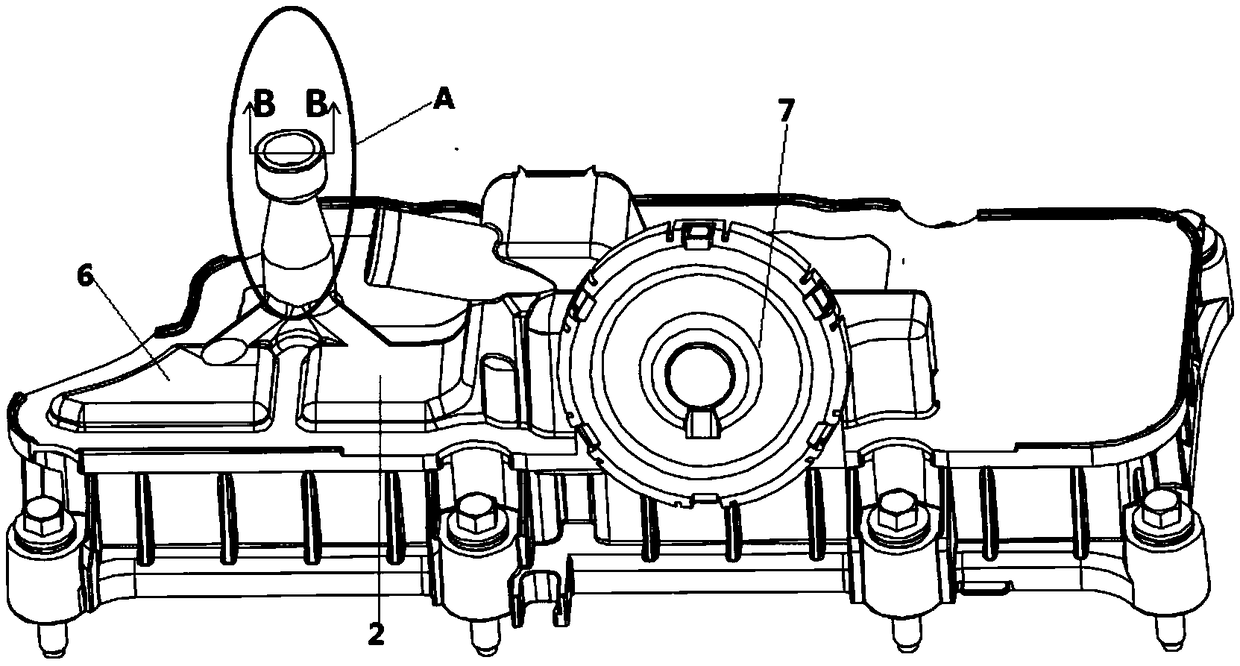

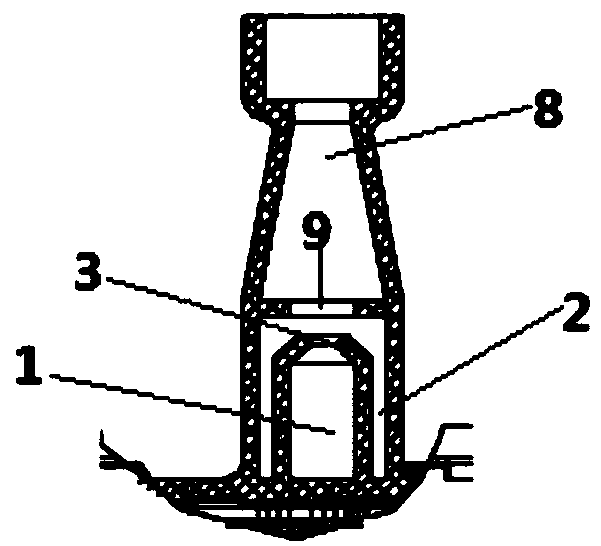

[0031] figure 2 is a three-dimensional schematic diagram of an oil-gas separator according to an embodiment of the present invention, image 3 yes figure 2 A schematic cross-sectional view along the B-B line in A area. see image 3 , see also figure 2 , this embodiment takes image 3 To explain to the Lord. The crankcase ventilation system oil-air separator assembly includes a booster chamber 1 and a separation chamber 2 . The gas inlet of the boost chamber 1 communicates with the supercharger for accommodating fresh air pressurized by the supercharger when the supercharger is in a transitional state. The separation chamber 2 communicates with the gas outlet 3 of the pressurization chamber 1 and is used to accommodate the waste gas separated by the oil-gas separator. Wherein, the flow area of the gas outlet 3 of the pressurized chamber 1 is smaller than the flow area of the gas inlet, so that the speed of the pressurized fresh air flowing out from the gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com