A variable voltage coagulation device for controlling the number of micro-nano particles

A particle number, micro-nano technology, applied in exhaust devices, noise reduction devices, machines/engines, etc., can solve the problem of low collection efficiency of small particle size particles, achieve particle size increase, improve collection efficiency, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention is further illustrated below with reference to the accompanying drawings.

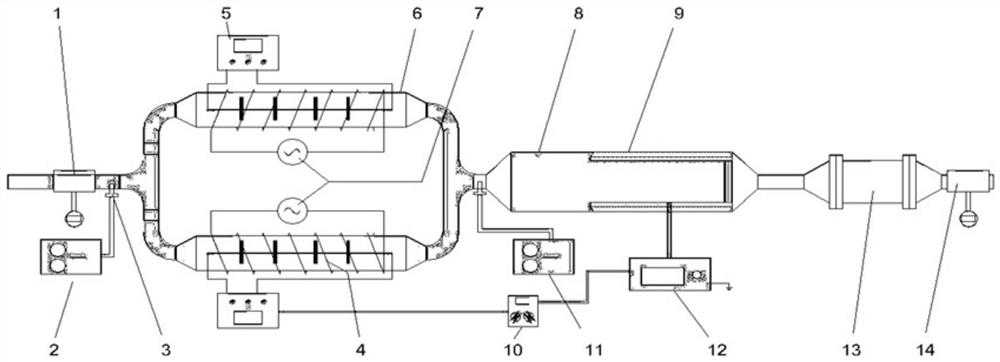

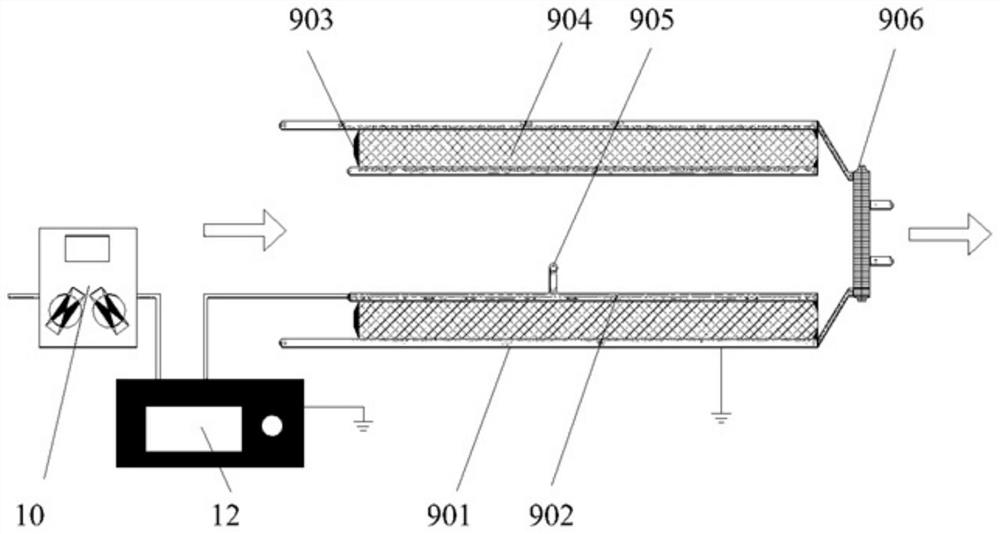

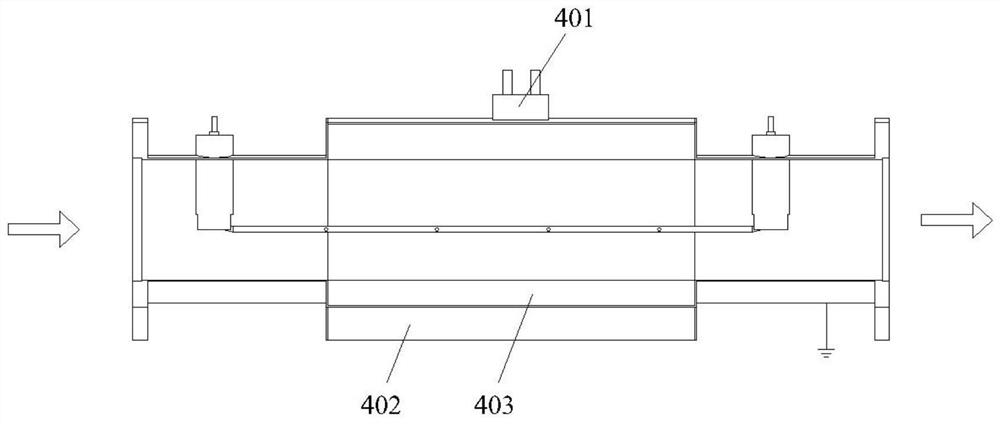

[0039]Such asfigure 1 As shown, the variable voltage reading and means for controlling the number of micro-nano-stage particles includes: mass flow meter (including first mass flow meter 1 and second mass flow meter 14), temperature sensor (including front temperature sensor 2, and after temperature sensor) 11), ceramic heater 4, particle load pad 6 and the particulate coinker 8, the high voltage power source 5, the Faraday barrel 9, the digital charger 12, the automatic controller 10, and the particle trap 13.

[0040]The first mass flow meter 1 is connected to the internal combustion engine exhaust end for measuring the initial exhaust mass flow, and the particles are partially adsorbed on the metal barrel wall after the bipolar particle porridge 6, the first mass flow meter. 1 Measure the change of the exhaust gas flow rate after the device is measured together with the second mass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com