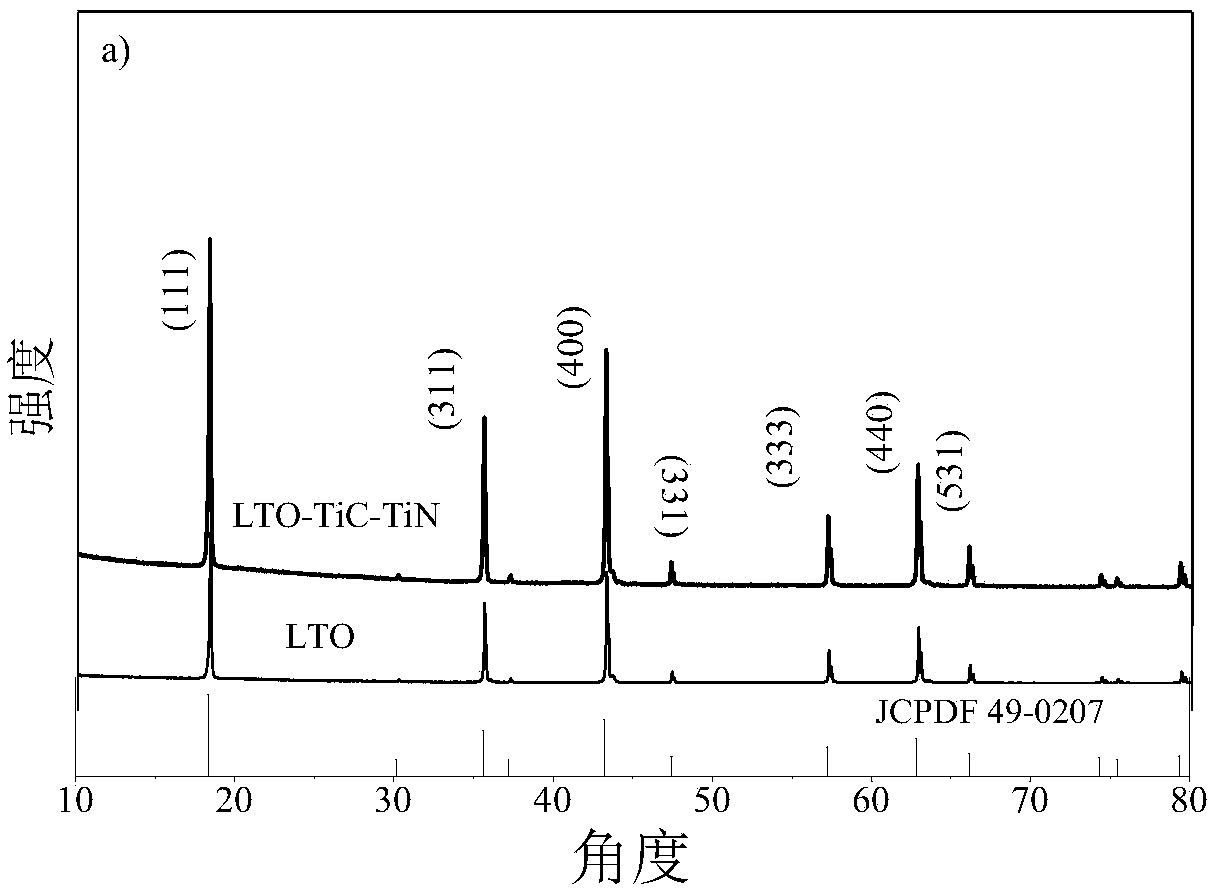

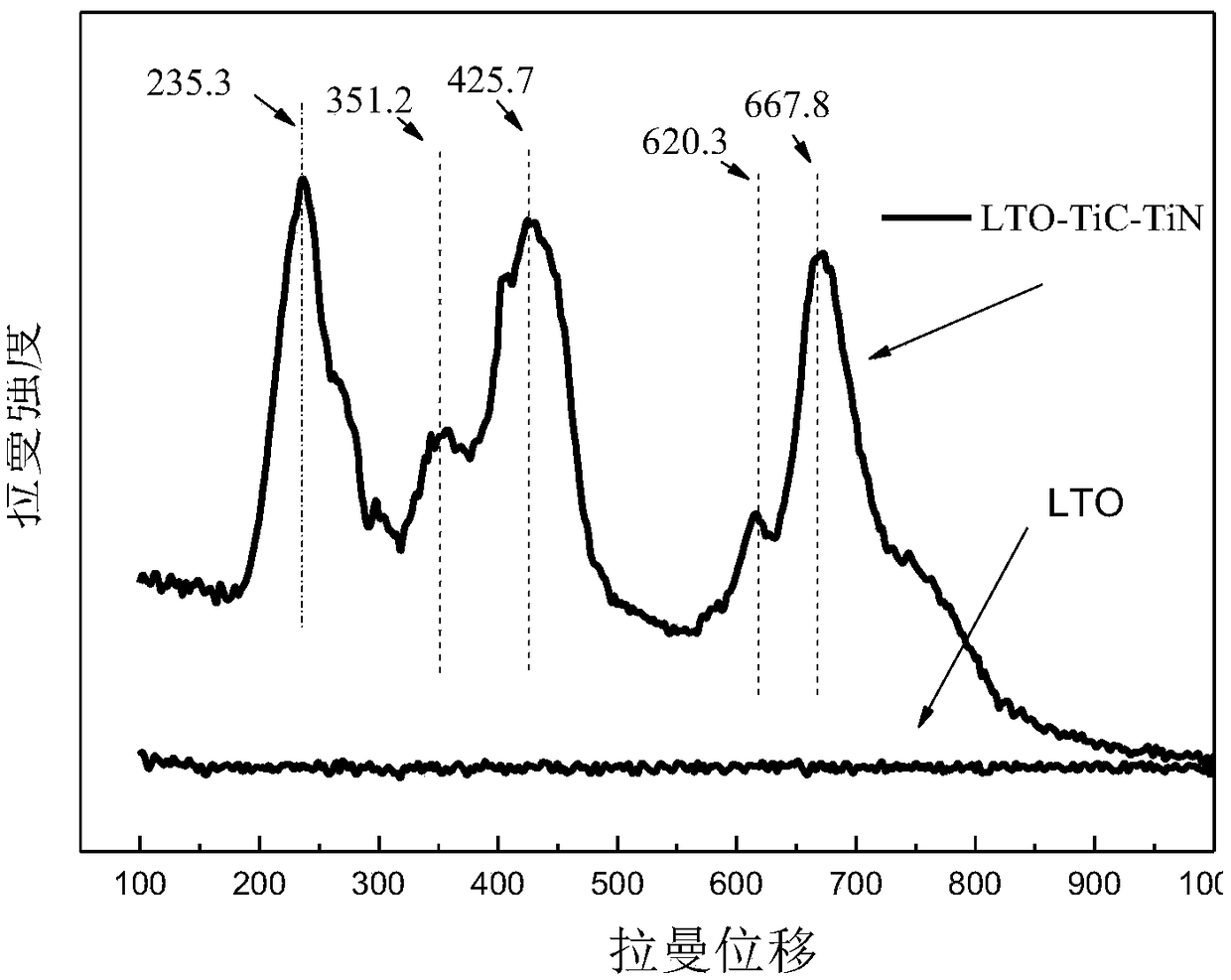

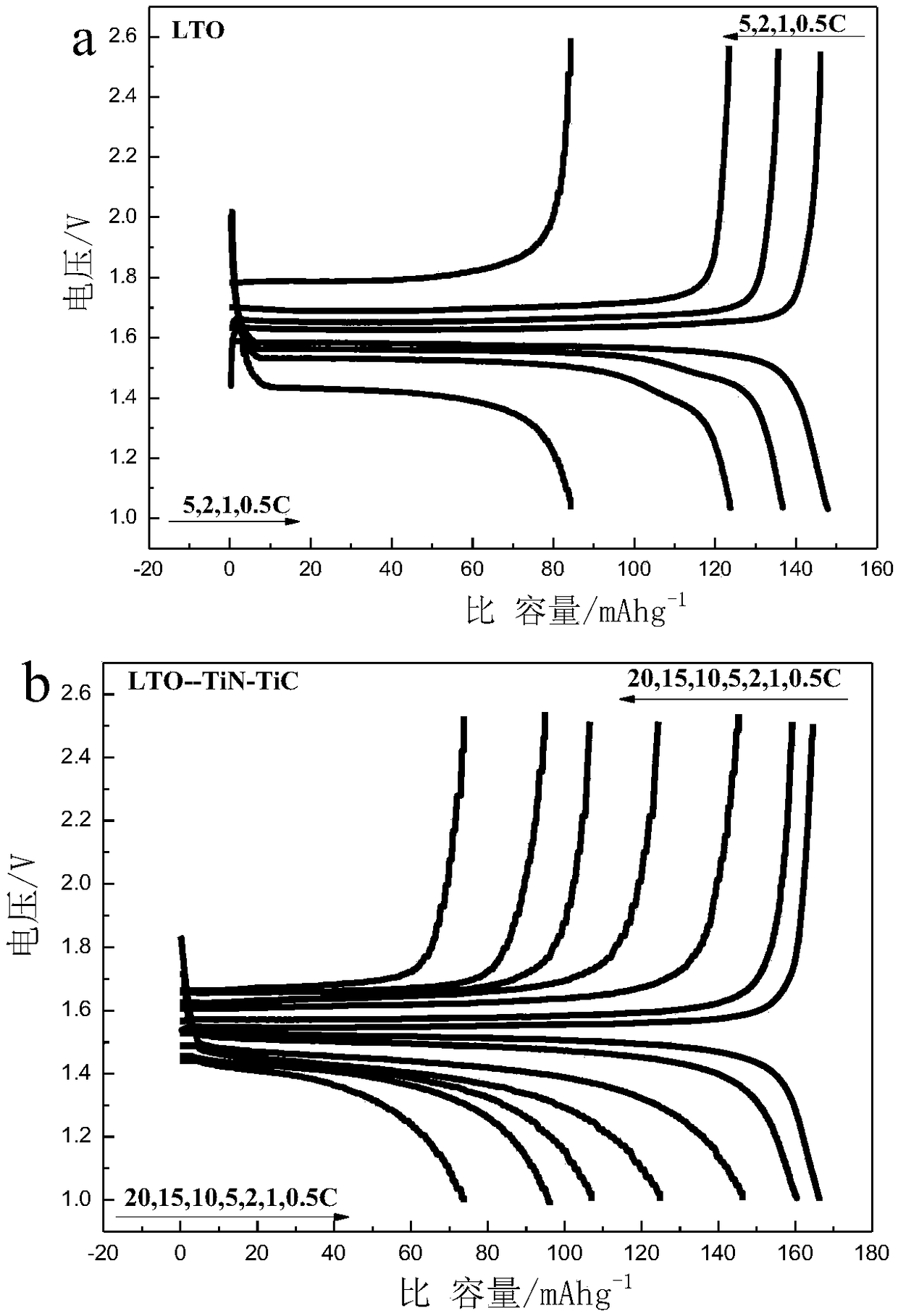

Li4Ti5O12-TiN-TiC material and preparation method thereof

A metal and total mass technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as complicated preparation process and expensive medicines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] With 13.1g TiO 2 As the initial titanium source for the reaction, 4.88gLi 2 CO 3 As the initial lithium source for the reaction, 4% metallic titanium powder and 2% graphite powder were added, and in an agate mortar, TiO 2 and Li 2 CO 3 Use an agate grinding rod to mix evenly, then add graphite powder and metal titanium powder to the mixture in proportion, and then use a stainless steel medicine spoon to mix evenly, put the above materials into a tube furnace, 2 Under the protection of gas, calcined at the highest calcination temperature of 850°C for 6h to obtain Li 4 Ti 5 o 12 -TiN-TiC composite material.

Embodiment 2

[0024] With 13.1g TiO 2 As the initial titanium source for the reaction, 4.88gLi 2 CO 3 As the initial lithium source for the reaction, 3% metallic titanium powder and 1% graphite powder were added. In an agate mortar, TiO 2 and Li 2 CO 3 Use an agate grinding rod to mix evenly, then add graphite powder and metal titanium powder to the mixture in proportion, and then use a stainless steel medicine spoon to mix evenly, put the above materials into a tube furnace, 2 Under the protection of gas, under the condition of the highest calcination temperature of 900 ℃, calcined for 8h to obtain Li 4 Ti 5 o 12-TiN-TiC composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap