Negative active material for rechargeable lithium battery and rechargeable lithium battery including same

A negative electrode active material, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of long charging time users complain about inconvenience, and achieve the effect of excellent electrolyte impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

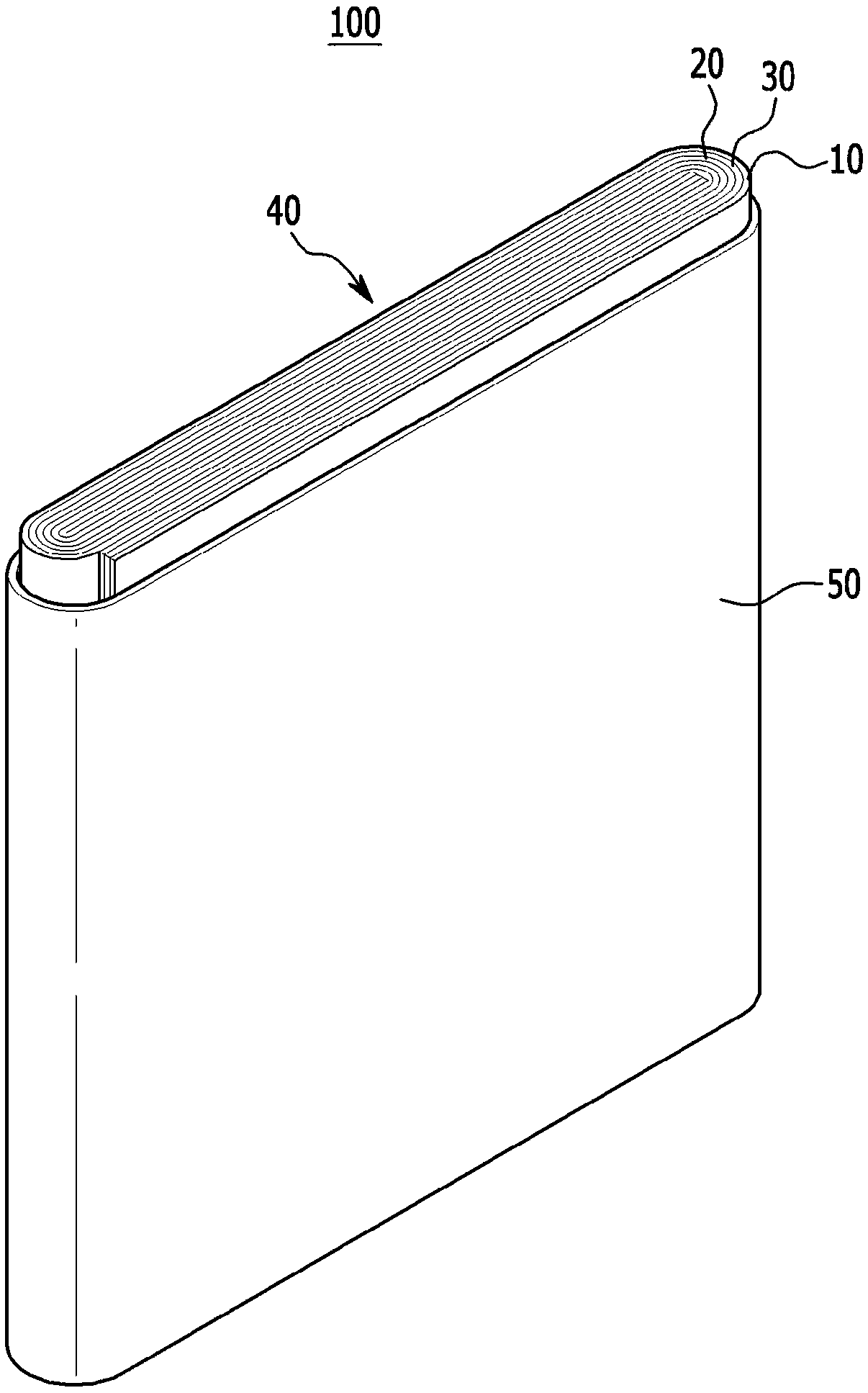

Image

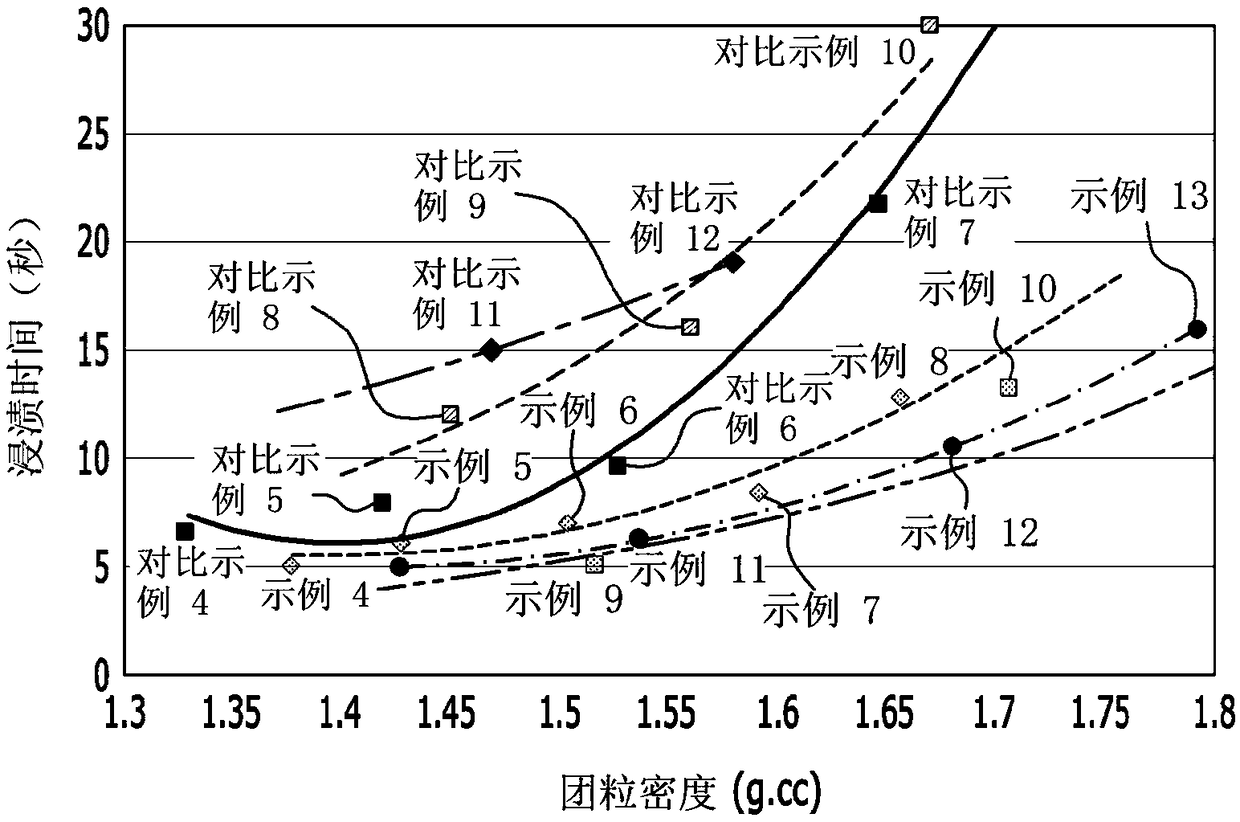

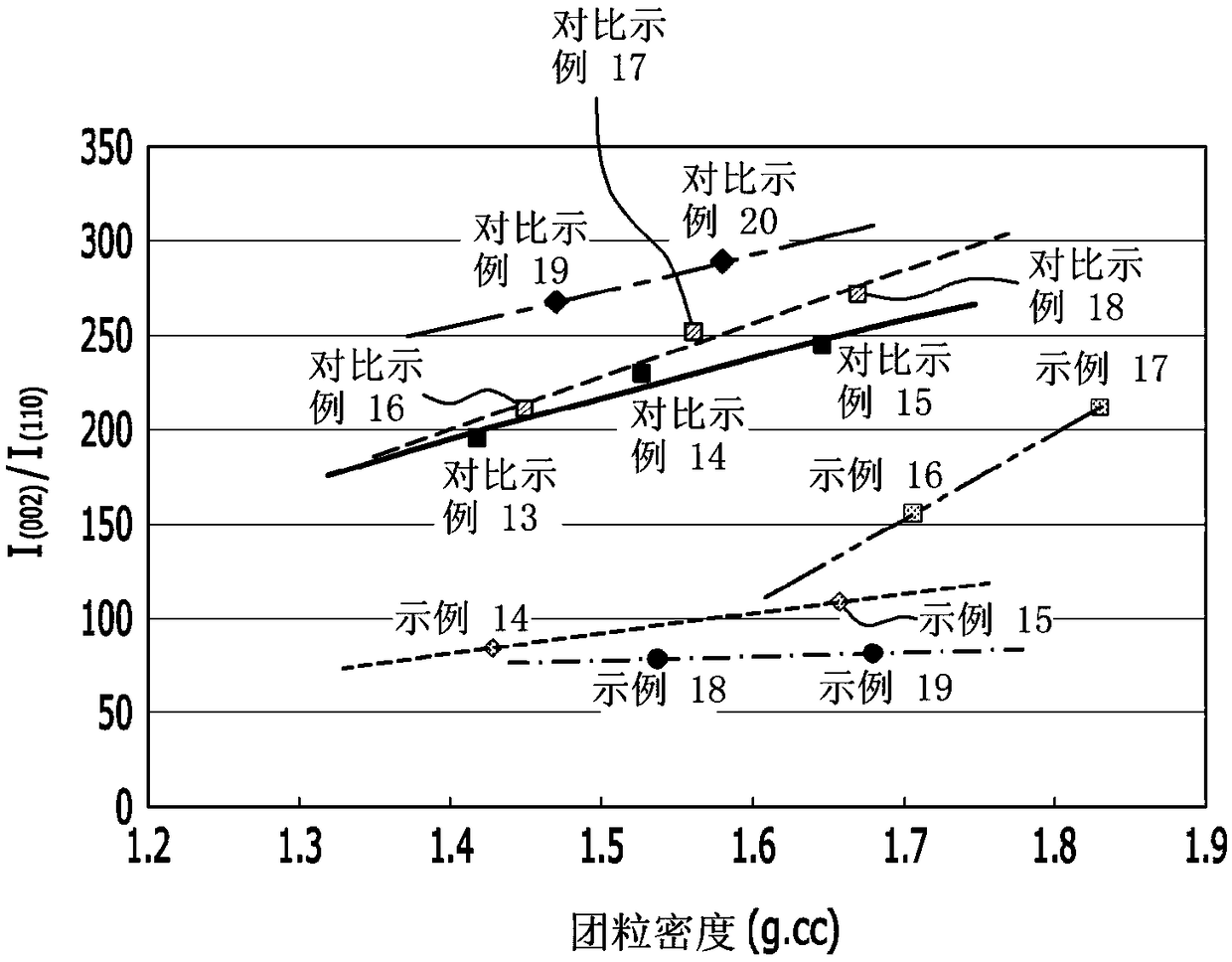

Examples

example 1

[0097] By mixing primary particles formed of needle coke-type artificial graphite and having an average particle diameter (D50) of 9.0 μm and an aspect ratio ranging from 1 to 5 with binder pitch in a weight ratio of 9:1 and making them Agglomerated to prepare a secondary particle negative active material having an average particle diameter (D50) of 20.5 μm. In the negative electrode active material, the ratio of the average particle diameter (D50) of the secondary particles / the average particle diameter (D50) of the primary particles was 2.28.

example 2

[0099] By mixing primary particles formed of needle coke-type artificial graphite and having an average particle diameter (D50) of 5.0 μm and an aspect ratio ranging from 1 to 5 with binder pitch in a weight ratio of 8:2 and making them Agglomerated to prepare a secondary particle negative active material having an average particle diameter (D50) of 13.5 μm. In the negative electrode active material, the average particle diameter (D50) of the secondary particles / average particle diameter (D50) of the primary particles was 2.70.

example 3

[0101] By mixing primary particles formed of needle coke-type artificial graphite and having an average particle diameter (D50) of 9.0 μm and an aspect ratio ranging from 1 to 5 with binder pitch in a weight ratio of 9:1 and making them Agglomerated to prepare a secondary particle negative active material having an average particle diameter (D50) of 18.4 μm. In the negative electrode active material, the average particle diameter (D50) of the secondary particles / average particle diameter (D50) of the primary particles was 2.04.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com