Molding and machining method of loose ceramic parts

A technology for forming and processing ceramic parts, applied in the field of forming and processing loose ceramic parts, can solve problems such as cracks and easy chipping, and achieve the effects of high cutting accuracy, improved processing efficiency, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

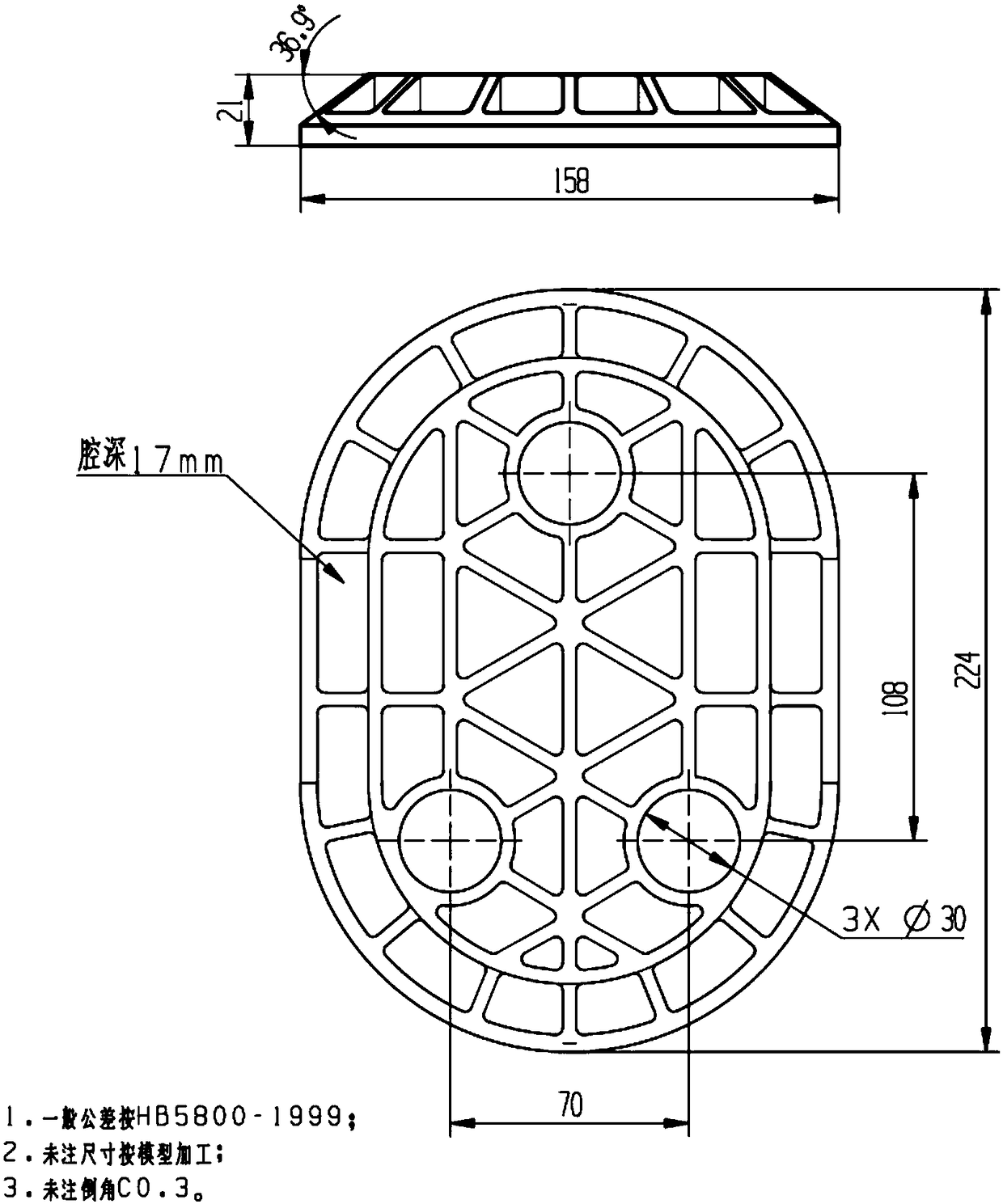

[0020] A method for forming and processing loose ceramic parts, the processing method comprising the following steps:

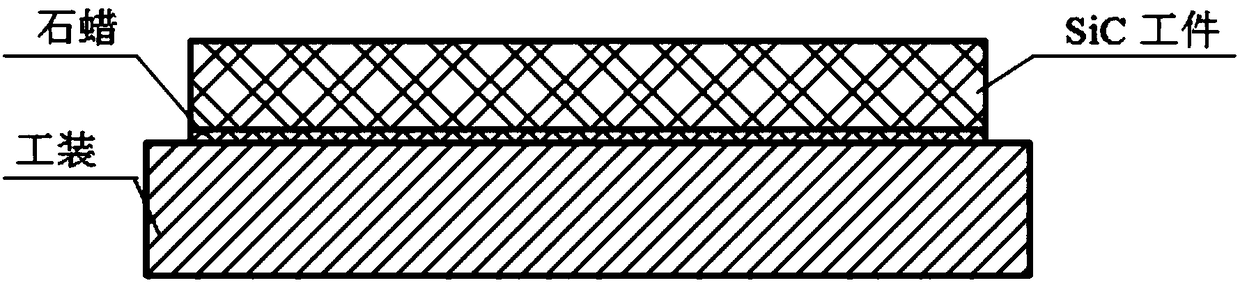

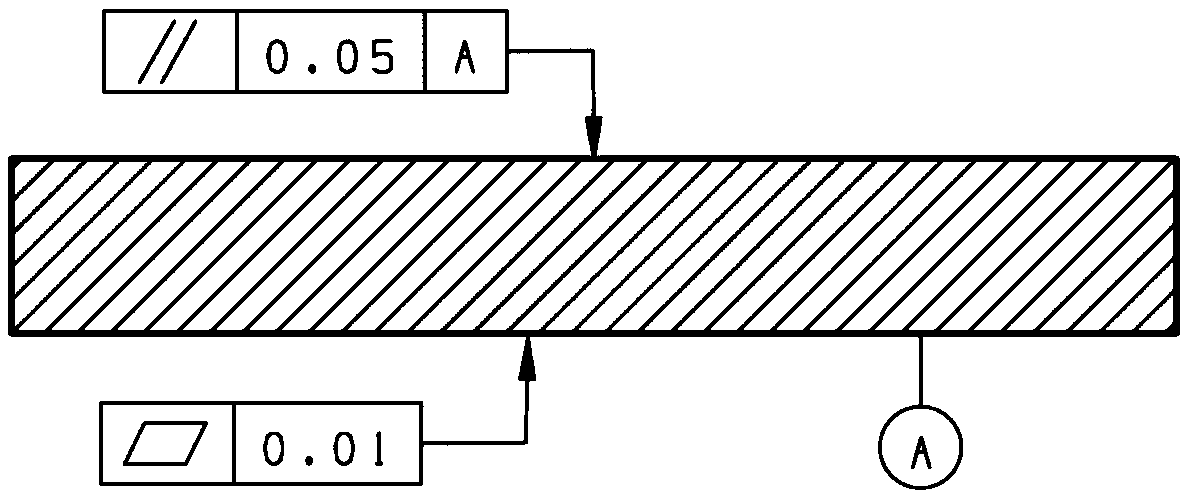

[0021] Step 1: Design the tooling base used to support the parts, and its flatness and parallelism are required to be within 0.01mm and 0.05mm respectively, such as figure 1 shown;

[0022] Step 2: Place the tooling base on the heating plate, and when the temperature of the tooling base reaches above 50°C, apply paraffin evenly on the assembly surface of the tooling base;

[0023] Step 3: If figure 2 As shown, place the loose ceramic body on the assembly surface of the tooling base, and take it off after cooling to room temperature;

[0024] Step 4: Use the mechanically processed combination fixture to complete the clamping of the bonded parts and perform mechanical processing;

[0025] Set the spindle speed (N), feed (f) and cutting amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com