A method for preparing self-healing materials based on aza-Michael addition

A self-healing material, a technology of diazabicyclo, which is applied in the field of self-healing material preparation based on aza-Michael addition, can solve problems such as damage and performance degradation, and achieve high reaction efficiency, improved service life, and reaction environment. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

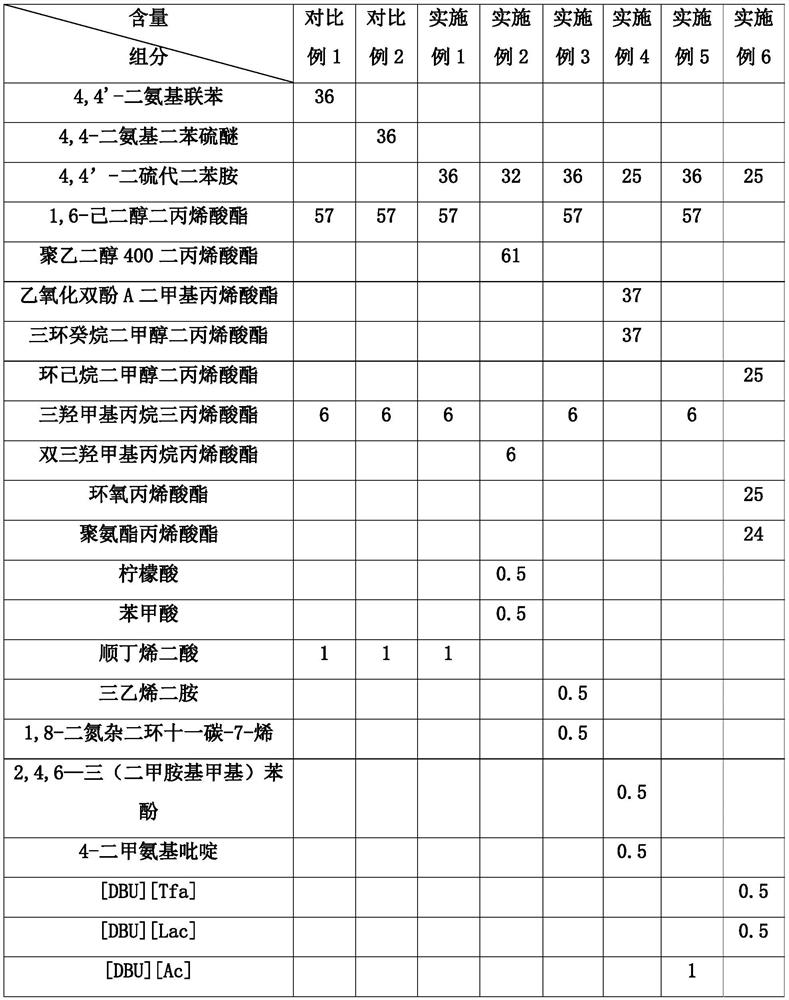

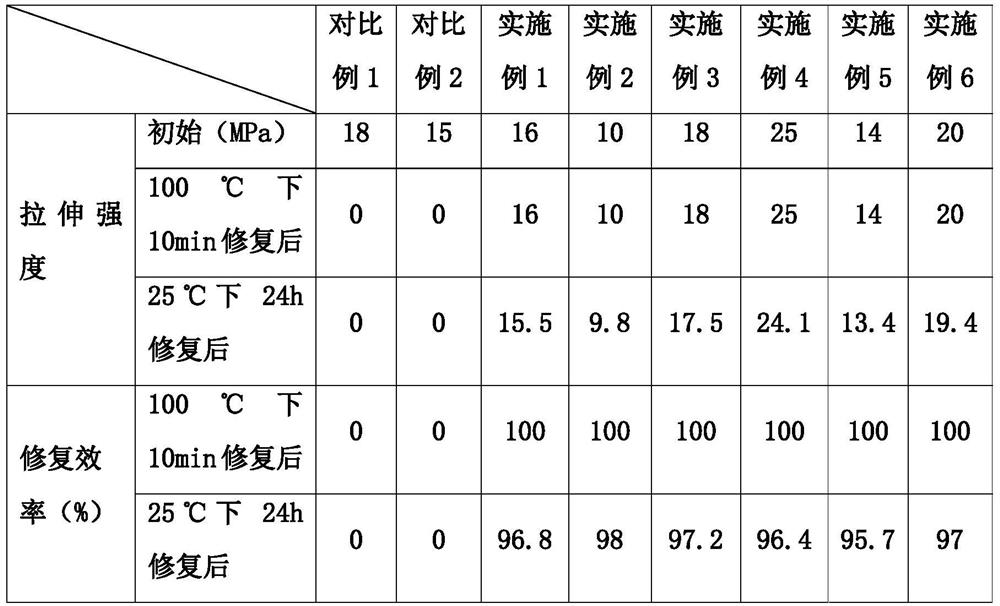

Embodiment 1

[0024] At 80°C, formulate the components according to Example 1 in Table 1, mix 4,4'-dithiodianiline, 1,6-hexanediol diacrylate and trimethylolpropane triacrylate at a low speed For 10 minutes, a homogeneous mixture was obtained. Maleic acid was then added and mixed uniformly by stirring at a low speed for 10 minutes at 150° C. to prepare a uniform prepolymer. Finally, put the prepared prepolymer into an oven at 150° C. for 10 hours to cure, and then the self-healing material of the present invention can be prepared.

Embodiment 2

[0026] At 80°C, formulate the components according to Example 2 in Table 1, mix 4,4'-dithiodianiline, polyethylene glycol 400 diacrylate and ditrimethylolpropane acrylate at low speed for 10 minutes , to obtain a homogeneous mixture. Then citric acid and benzoic acid were added and mixed uniformly by stirring at a low speed for 10 minutes at 150° C. to prepare a uniform prepolymer. Finally, put the prepared prepolymer into an oven at 150° C. for 10 hours to cure, and then the self-healing material of the present invention can be prepared.

Embodiment 3

[0028] At 80°C, formulate the components according to Example 3 in Table 1, mix 4,4'-dithiodianiline, 1,6-hexanediol diacrylate and trimethylolpropane triacrylate at a low speed For 10 minutes, a homogeneous mixture was obtained. Then triethylenediamine and 1,8-diazabicycloundec-7-ene were added, and the mixture was uniformly mixed by stirring at a low speed for 10 minutes at 150° C. to prepare a uniform prepolymer. Finally, put the prepared prepolymer into an oven at 150° C. for 10 hours to cure, and then the self-healing material of the present invention can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com