Terylene multifunctional fancy yarns and preparation method thereof

A fancy yarn and multi-functional technology, applied in the textile field, can solve the problems of complex production process, single function, high cost, etc., and achieve the effect of excellent shading performance, comfortable hand feeling and strong sense of hierarchy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

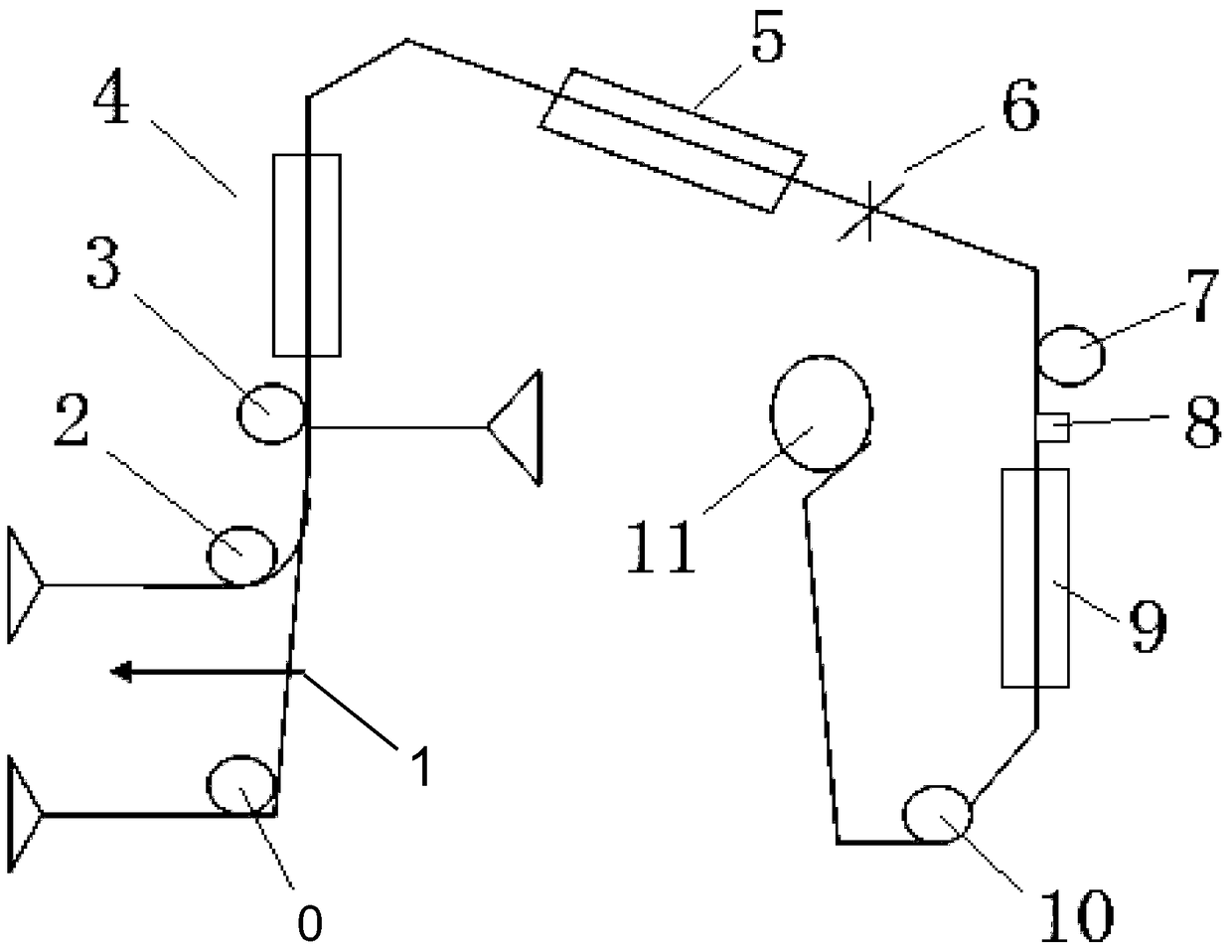

[0058] A preparation method of polyester multifunctional fancy yarn, comprising the following steps:

[0059] 1) The cationic MOY yarn is fed through the zero roller, and under the reciprocating swing of the swing rod, it is intermittently heated by the hot roller, and then enters the first roller. The draft ratio DR of cationic MOY yarn between zero roller and one roller 01 It is 1.55-1.65.

[0060] 2) At the same time, two kinds of fine denier porous flame-retardant POY yarns are pre-networked first, and then fed into the first roller after being fed by another zero roller. The draft ratio DR between zero roller and one roller of fine denier porous flame retardant POY yarn 02 0.98-1.0.

[0061] 3) The cationic MOY yarn, the fine denier porous flame-retardant POY yarn and the full-dull FDY yarn converge at a roller, and the main draft DR is 1.05-1.1. Then draw, deform (200-220°C), cool, false twist, network composite, shape (180-200°C), and wind in sequence to obtain poly...

Embodiment 1

[0064] The cationic MOY yarn was prepared by spinning, with a specification of 273dtex / 48f, a breaking strength of 1.75 cn / dtex, and a breaking elongation of 175%; a full-dull FDY yarn specification of 167 dtex / 72f, a breaking strength of 3.1cn / dtex, and a breaking elongation of 27 %; fine denier porous flame-retardant POY yarn, phosphorus content is 6600ppm, specifications are 365 dtex / 288 f, 142 dtex / 144f respectively, the breaking strength of the former is 2.05 cn / dtex, and the elongation at break is 128%; the breaking strength of the latter is 2.03 cn / dtex, elongation at break 125%.

[0065] The cationic MOY yarn passes through the zero roller, and under the action of the reciprocating swing bar, it is intermittently heated by the hot roller, and the other two specifications of the fine denier porous flame-retardant POY yarn pass through another zero roller without drafting and full extinction The FDY yarns meet at a roller, and are sequentially drawn, deformed, cooled,...

Embodiment 2

[0069] The cationic MOY yarn was prepared by spinning, with a specification of 205dtex / 48f, a breaking strength of 1.70 cn / dtex, and a breaking elongation of 180%. The full-dull FDY yarn had a specification of 111 dtex / 72f, a strength of 3.3cn / dtex, and an elongation of 25%. Fine-denier porous flame-retardant POY yarn with a phosphorus content of 6600ppm and specifications of 270dtex / 288f and 142dtex / 144f respectively. The breaking strength of the former is 2.08 cn / dtex and the elongation at break is 126%; The elongation at break is 125%.

[0070] In Example 2, the fine-denier porous flame-retardant POY yarns, cationic MOY yarns and full-dull FDY yarns are all made of polyester chips as raw materials through twin-screw extrusion and spinning. The preparation method of polyester chip is:

[0071] Preparation of silicon-titanium composite homogeneous catalyst: Add 74.4g (1.2mol) of ethylene glycol into a 500ml flask equipped with a magnetic stirring and condensation device, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com