Centralized heat supply system and method

A technology of central heating and heat exchange system, applied in hot water central heating system, heating system, heating method, etc., can solve the problems such as inability to carry out, difficult to withstand the temperature and pressure of high temperature hot water, poor matching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

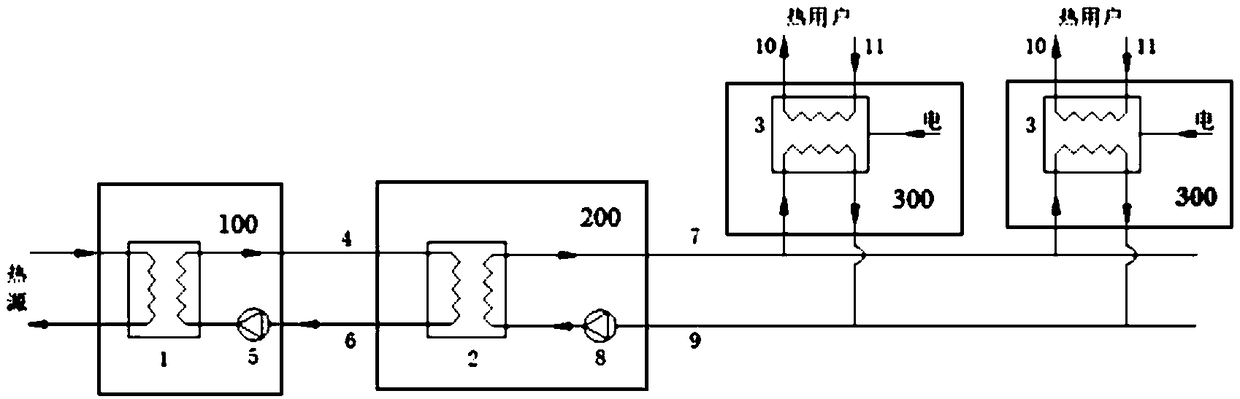

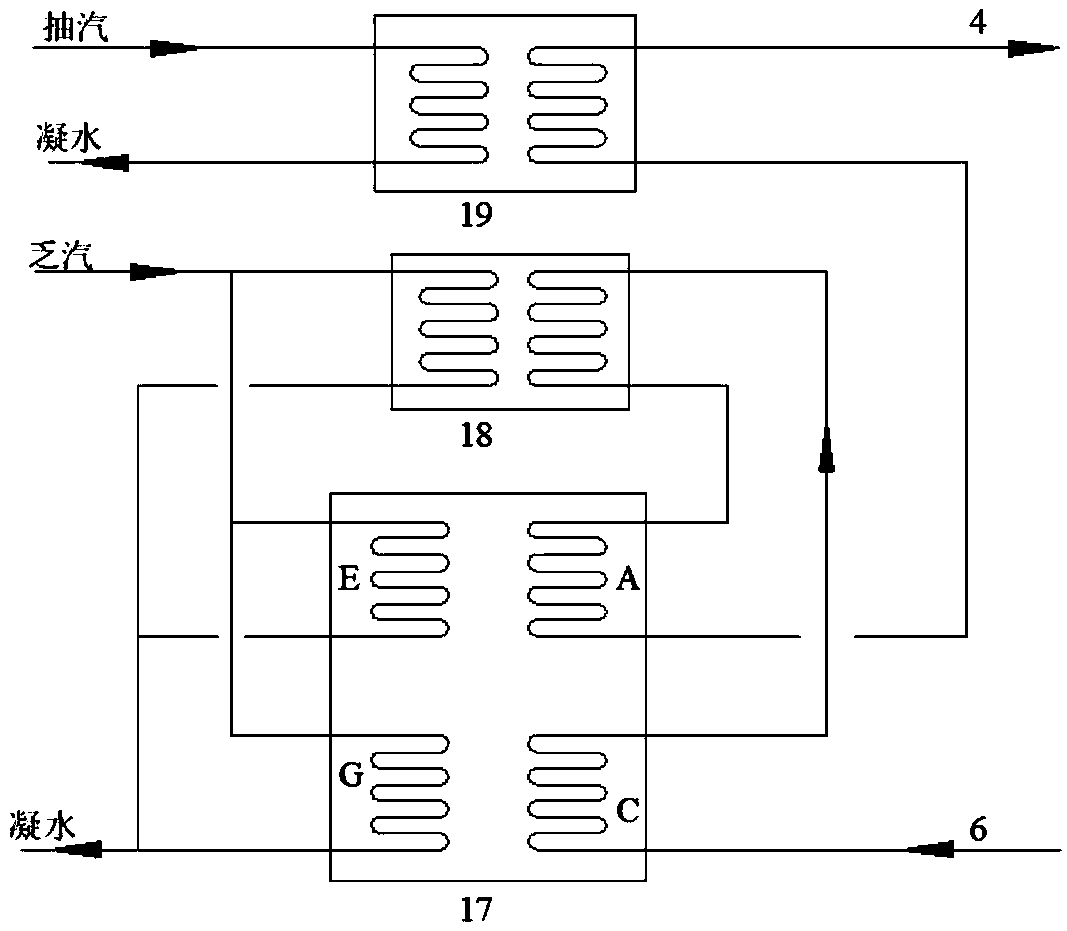

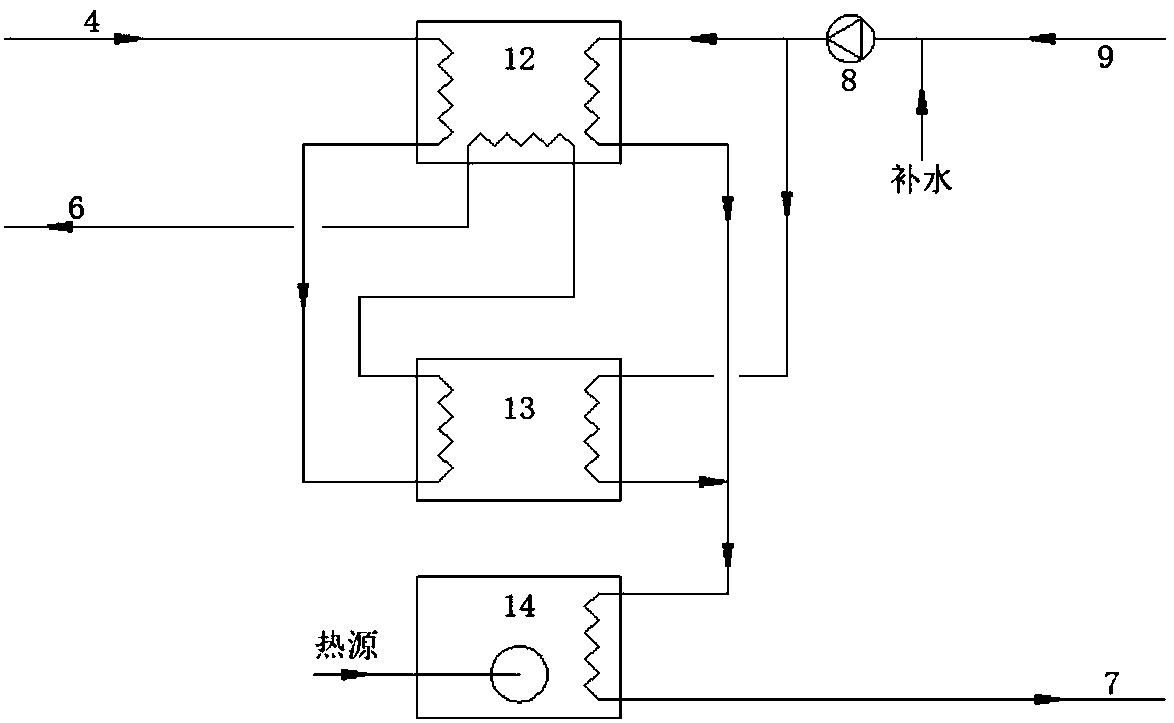

[0062] Embodiment 1: A central heating system

[0063] Generally speaking, central heating system of the present invention such as figure 1 and Figure 5 As shown, the central heating system includes a heat source heat exchange system 100, multiple absorption heat exchange systems 200 and multiple compression heat exchange systems 300, and the heat release side of the heat source heat exchange system 100 is used to communicate with the heat supply of the heat source The medium inlet and outlet pipes; the heat-taking side of the heat source heat exchange system 100 and the heat-releasing side of the absorption heat exchange system 200 are connected through the primary network water supply pipe 4 and the primary network return water pipe 6; the absorption heat exchange system 200 The heat extraction side and the heat release side of the compression heat exchange system 300 are connected through the secondary network water supply pipeline 7 and the secondary network return water...

Embodiment 2

[0084] Embodiment 2: Central heating system different from the heat source heat exchange device in Embodiment 1

[0085] On the basis of Example 1, the heat source heat exchange device 1 of the central heating system provided by this example is as follows: Figure 6 and Figure 7 As shown, the heat source heat exchange device 1 includes N steam turbine condensers 15-1, 15-2, ... 15-N and a second peak regulation heater 16, N steam turbine condensers 15-1, 15-2, ... 15-N are connected in series through pipelines from front to back, the water inlet of the steam turbine condenser 15-N at the end is connected with the water outlet of the first circulation pump 5, and the water outlet of the steam turbine condenser 15-1 at the front is connected with the water outlet of the first circulating pump 5 The water inlet of the second peak regulation heater 16 is connected, and the water outlet of the second peak regulation heater 16 is connected with the water inlet of the primary netwo...

Embodiment 3

[0091] Embodiment 3, a kind of central heating method

[0092] Adopt the centralized heating system that above-mentioned embodiment 1 or embodiment 2 provide, as figure 1 As shown, the central heating method generally includes the following steps:

[0093] Step A: exchanging heat between the heat source medium and the primary net water;

[0094] Step B: Circulate the network water once;

[0095] Step C: exchanging heat between the primary mesh water and the secondary mesh water;

[0096] Step D: Circulating secondary network water;

[0097] Step E: exchanging heat between the secondary mesh water and the tertiary mesh water;

[0098] Step F: Perform three network water supply and return water.

[0099] Specifically, step A includes the following steps:

[0100] Step A1: The inlet of the heat release side of the heat source heat exchange device 1 receives the heat source heating medium transported by the heat supply pipeline of the heat source, and transmits the heat ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com