Automatic surface defect detecting device and automatic surface defect detecting method for large-opening curved-surface optical elements

An automatic detection device and technology for optical components, applied in the direction of optical components, optical testing flaws/defects, measuring devices, etc., can solve problems such as poor subjective judgment accuracy, scratches, and affecting optical system performance, and achieve detection accuracy and detection Effects of improved efficiency, improved imaging contrast and signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

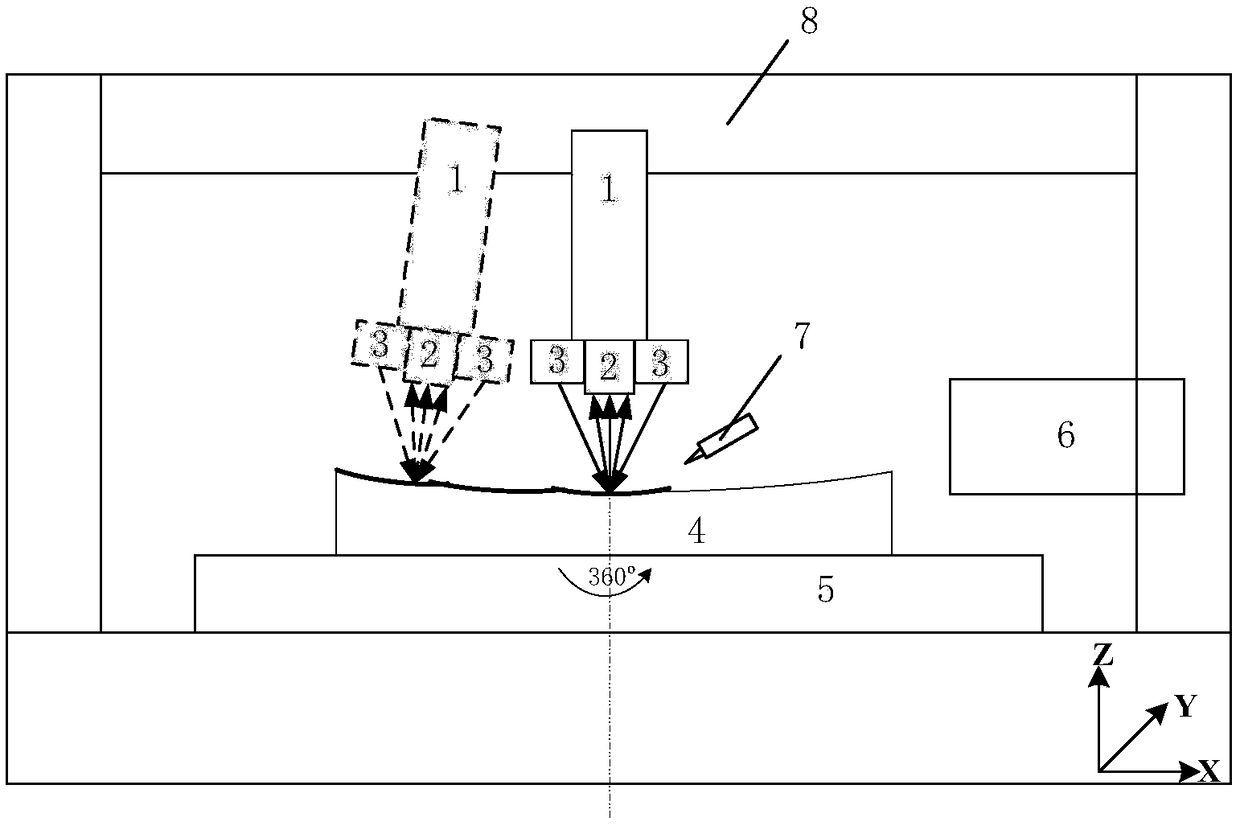

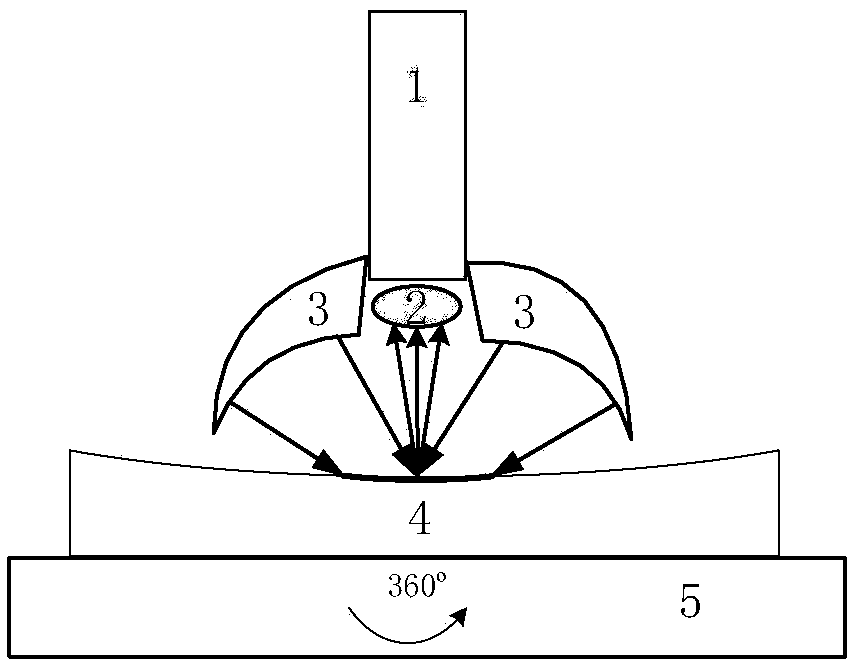

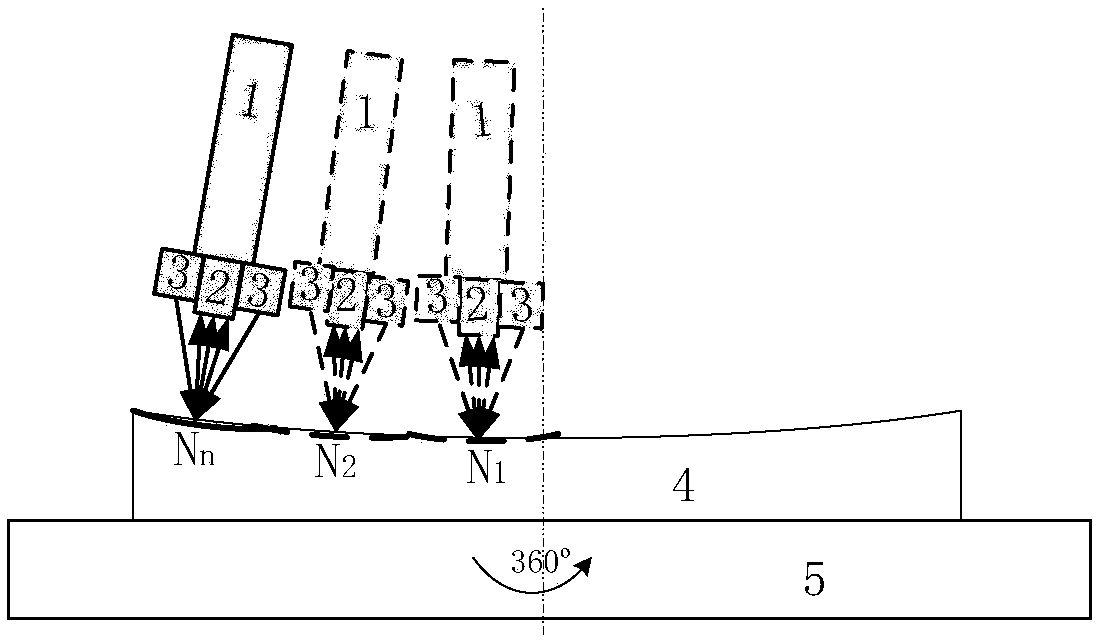

[0026] Such as figure 1 As shown, in the embodiment of the present invention, an automatic detection device for surface defects of a large-diameter curved optical element includes a sensor system 1, an imaging system 2, an illumination system 3, a large-diameter optical element 4, a rotating workpiece table 5, and an automatic sampling device 6. Spray device 7, guide rail 8. Among them, the large-diameter optical element 4 is placed on the workpiece table 5 that can rotate 360 degrees around the Z axis. The sensor system 1, the imaging system 2, and the lighting system 3 form a measuring head. The measuring head is vertically installed on the guide rail 8 to realize the large-diameter optical The multi-axis linkage of the component, including the translation along the X and Z axes and the swing around the Y axis, ensures that the optical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com