Compound sulfamonomethoxine microcapsule preparation and preparation method thereof

A technology of sulfa-metamethoxine and methoxine, which is applied in the field of compound sulfa-metamethoxine microcapsule preparation and its preparation, can solve the problems of organic solvent consumption, body stimulation, etc., and achieve simple production process, save production cost, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

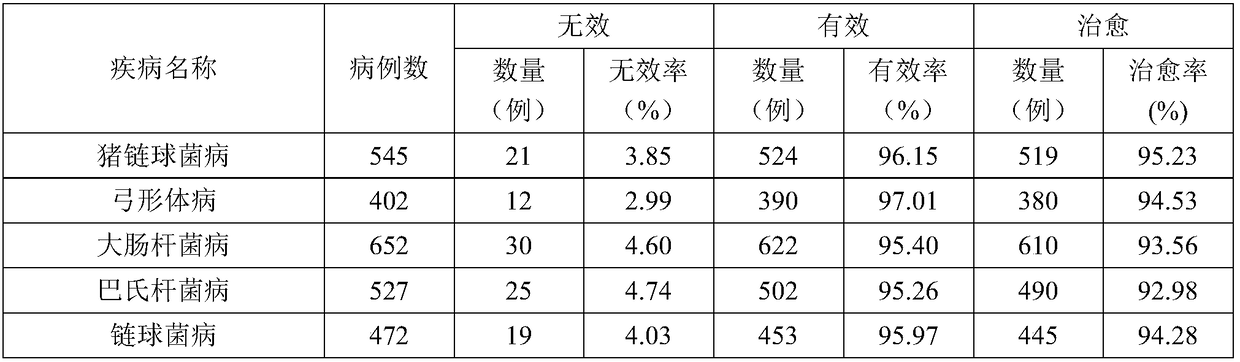

Examples

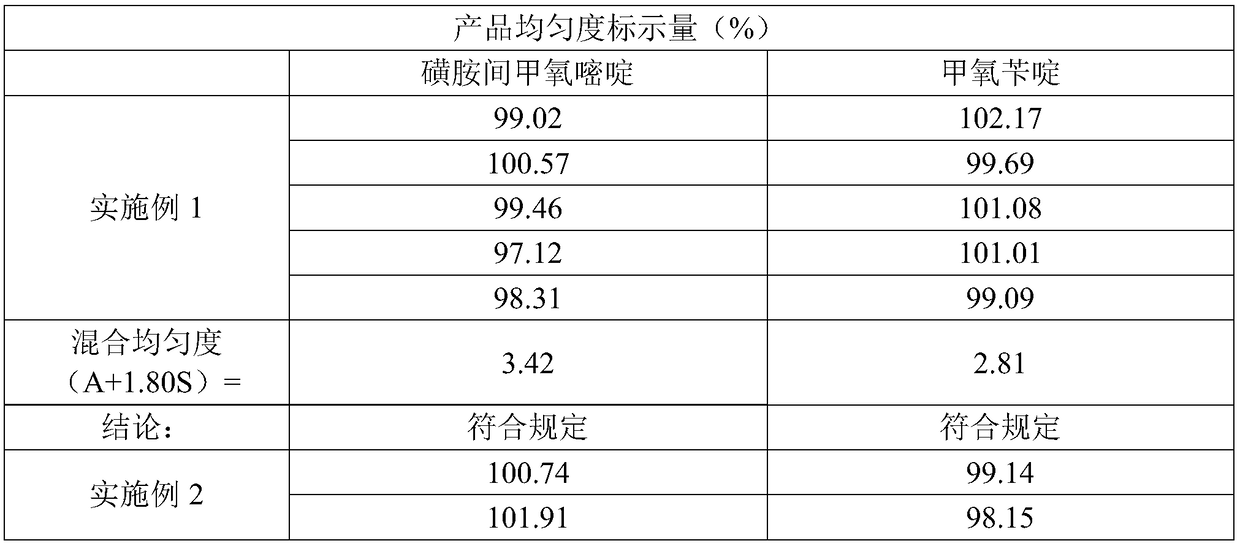

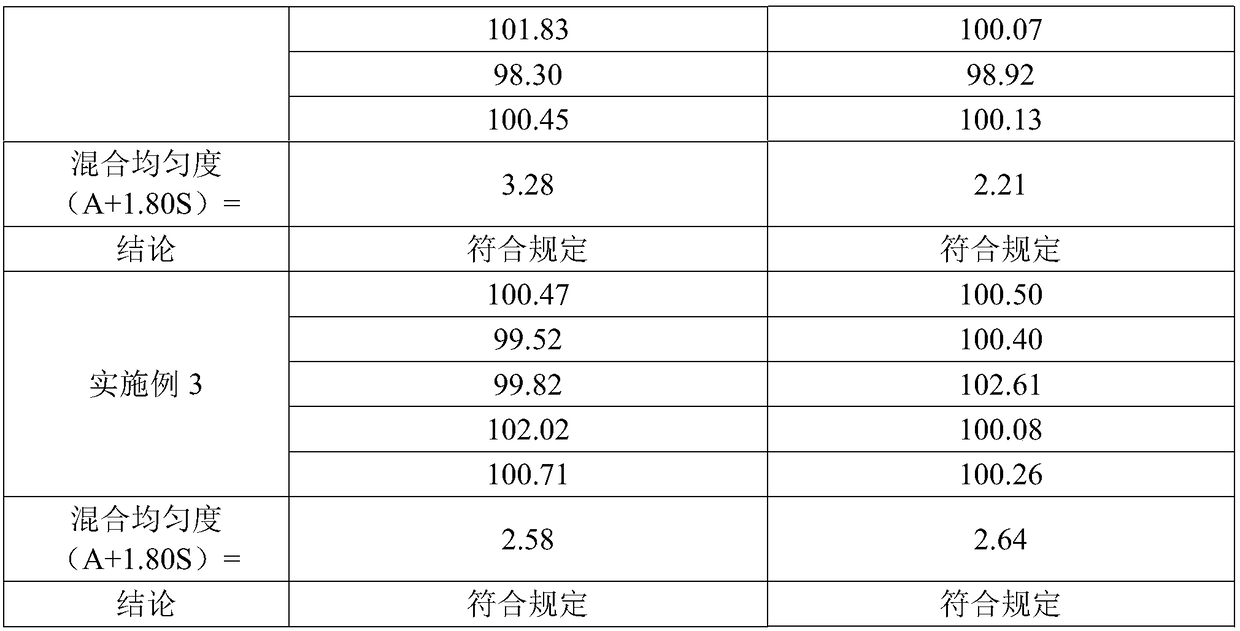

Embodiment 1

[0021] A compound sulfamonomethoxine microcapsule preparation, in parts by mass, prepared from the following raw materials: 10.0 parts by weight of sulfamethoxine, 2.1 parts by weight of trimethoprim, 61.9 parts by weight of sustained-release agent, and organic The solvent is 6.0 parts by weight and the filler is 20.0 parts by weight.

[0022] The sustained-release agent is monoglyceride, the organic solvent is PEG4000, and the filler is a mixture of starch and light calcium carbonate. The mixing mass ratio of the two is 1:1.

[0023] The preparation steps are:

[0024] 1) Set the water heating temperature of the emulsification tank to 95°C, put 61.9 parts by weight of monoglyceride and 6.0 parts by weight of PEG4000 into the emulsification tank, and when the temperature of the material rises to about 80°C, start stirring to make the material completely melted.

[0025] 2) After the materials are completely melted, adjust the emulsification tank water heating temperature to 82°C, turn...

Embodiment 2

[0029] A compound sulfamonomethoxine microcapsule preparation, based on parts by mass, prepared from the following raw materials: 5.0 parts by weight of sulfamethoxine, 4.0 parts by weight of trimethoprim, 55.0 parts by weight of sustained-release agent, and organic 10.0 parts by weight of solvent and 26.0 parts by weight of filler.

[0030] The sustained-release agent is monoglyceride, the organic solvent is PEG4000, and the filler is a mixture of starch and light calcium carbonate. The mixing mass ratio of the two is 1:1.

[0031] The preparation steps are:

[0032] 1) Set the water heating temperature of the emulsification tank to 95°C, put 55.0 parts by weight of monoglyceride and 10.0 parts by weight of PEG4000 into the emulsification tank, and when the temperature of the material rises to about 80°C, start stirring to make the material completely melted.

[0033] 2) After the materials are completely melted, adjust the emulsification tank water heating temperature to 82°C, turn ...

Embodiment 3

[0037] A compound sulfamonomethoxine microcapsule preparation, based on parts by mass, prepared from the following raw materials: 20.0 parts by weight of sulfamethoxine, 1.0 part by weight of trimethoprim, 65.0 parts by weight of sustained-release agent, and organic The solvent is 4.0 parts by weight, and the filler is 10.0 parts by weight.

[0038] The sustained-release agent is monoglyceride, the organic solvent is PEG4000, and the filler is a mixture of starch and light calcium carbonate. The mixing mass ratio of the two is 1:1.

[0039] The preparation steps are:

[0040] 1) Set the water heating temperature of the emulsification tank to 95°C, put 65.0 parts by weight of monoglyceride and 4.0 parts by weight of PEG4000 into the emulsification tank, and when the temperature of the material rises to about 80°C, start stirring to make the material completely melted.

[0041] 2) After the materials are completely melted, adjust the emulsification tank water heating temperature to 82°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com