A kind of compound sulfamethoxine microcapsule preparation and preparation method thereof

A technology of sulfamonomethoxine and methoxypyrim, which is applied in the field of compound sulfamonomethoxine microcapsule preparation and preparation thereof, can solve the problems of consumption of organic solvent, body stimulation and the like, and achieves simple production process, saving production cost, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

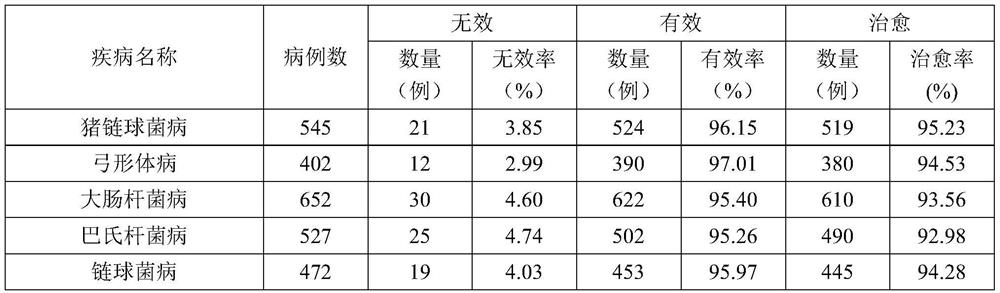

Examples

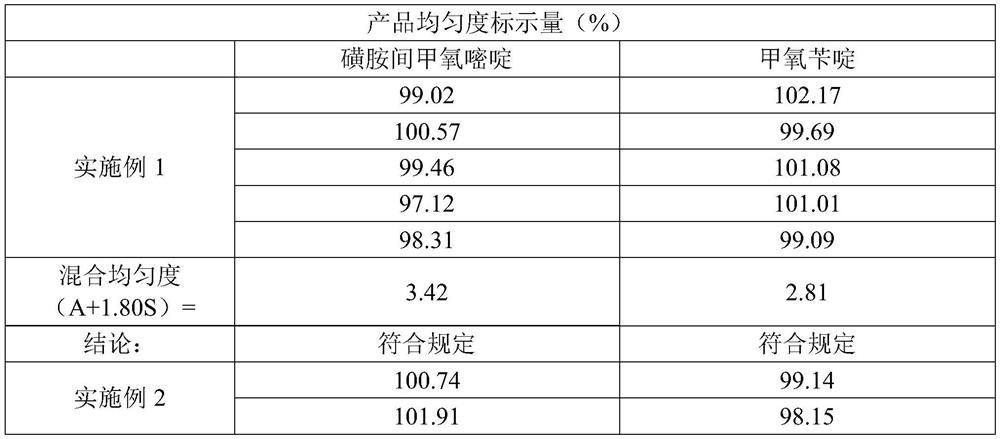

Embodiment 1

[0021] A compound sulfamethoxine microcapsule preparation prepared in parts by mass from the following raw materials: 10.0 parts by weight of sulfamethoxine, 2.1 parts by weight of trimethoprim, 61.9 parts by weight of a sustained-release agent, organic 6.0 parts by weight of solvent, and 20.0 parts by weight of filler.

[0022] The sustained-release agent is monoglyceride, the organic solvent is PEG4000, the filler is a mixture of starch and light calcium carbonate, and the mixing mass ratio of the two is 1:1.

[0023] Its preparation steps are:

[0024] 1) Set the water heating temperature of the emulsification tank to 95°C, put 61.9 parts by weight of monoglyceride and 6.0 parts by weight of PEG4000 into the emulsification tank, and when the temperature of the materials rises to about 80°C, start stirring to completely melt the materials.

[0025] 2) After the materials are completely melted, adjust the heating temperature of the water in the emulsification tank to 82°C, s...

Embodiment 2

[0029] A compound sulfamethoxine microcapsule preparation prepared in parts by mass from the following raw materials: 5.0 parts by weight of sulfamethoxine, 4.0 parts by weight of trimethoprim, 55.0 parts by weight of a sustained-release agent, organic 10.0 parts by weight of solvent, and 26.0 parts by weight of filler.

[0030] The sustained-release agent is monoglyceride, the organic solvent is PEG4000, the filler is a mixture of starch and light calcium carbonate, and the mixing mass ratio of the two is 1:1.

[0031] Its preparation steps are:

[0032] 1) Set the water heating temperature of the emulsification tank to 95°C, put 55.0 parts by weight of monoglyceride and 10.0 parts by weight of PEG4000 into the emulsification tank, and when the temperature of the materials rises to about 80°C, start stirring to completely melt the materials.

[0033] 2) After the materials are completely melted, adjust the heating temperature of the water in the emulsification tank to 82°C, ...

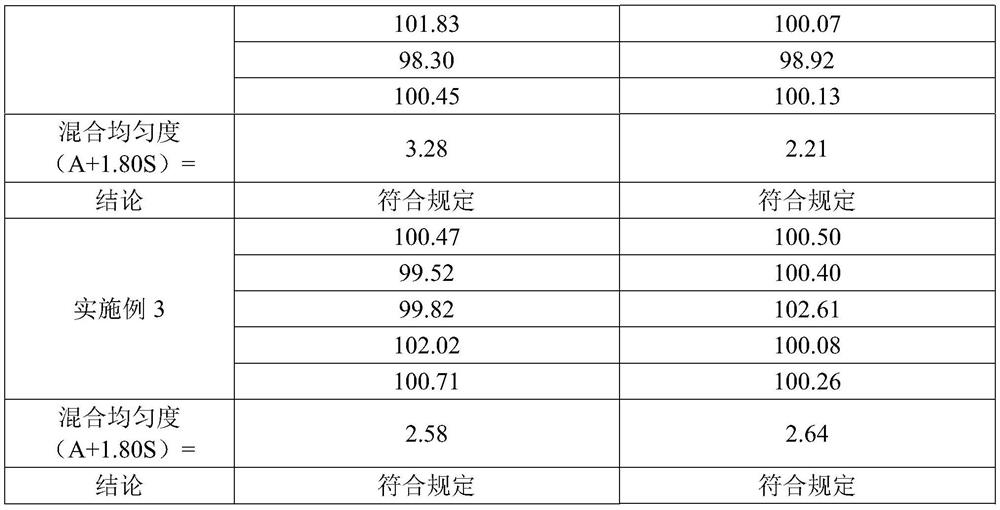

Embodiment 3

[0037] A compound sulfamethoxine microcapsule preparation prepared in parts by mass from the following raw materials: 20.0 parts by weight of sulfamethoxine, 1.0 parts by weight of trimethoprim, 65.0 parts by weight of a sustained-release agent, organic 4.0 parts by weight of solvent, and 10.0 parts by weight of filler.

[0038] The sustained-release agent is monoglyceride, the organic solvent is PEG4000, the filler is a mixture of starch and light calcium carbonate, and the mixing mass ratio of the two is 1:1.

[0039] Its preparation steps are:

[0040] 1) Set the heating temperature of the water in the emulsification tank to 95°C, put 65.0 parts by weight of monoglyceride and 4.0 parts by weight of PEG4000 into the emulsification tank, and when the temperature of the materials rises to about 80°C, start stirring to completely melt the materials.

[0041] 2) After the materials are completely melted, adjust the water heating temperature of the emulsification tank to 82°C, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com